Adjusting platform installed on workbench

A technology for adjusting platforms and worktables, applied in the directions of worktables, manufacturing tools, workpiece clamping devices, etc., can solve problems such as the inability to guarantee the flatness of the platform, the inconvenience of the plastic platform, and the displacement of the plastic platform, so as to avoid discomfort and injury. , to avoid phantom, to avoid the effect of easy displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

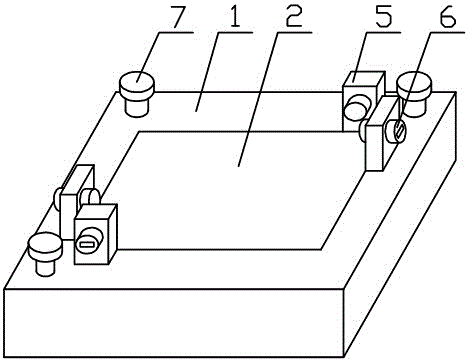

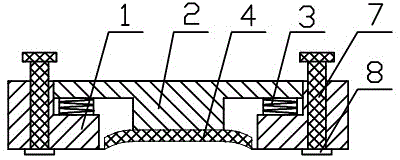

[0013] The present invention includes a loading seat 1, a loading platform 2, a spring 3, an elastic suction pad 4, a positioning block 5, a fixing screw 6, a level adjustment screw 7, and a support gasket 8. When installing, first install the four level adjustment screws 7 respectively At the four corners of the loading seat 1, install the supporting spacer 8 on the lower end of the horizontal adjustment screw 7, install the clamping screw on the positioning block 5, install the positioning block 5 on the loading seat 1, and then place the elastic suction The pad 4 is installed on the lower end of the loading platform 2, and finally the loading platform 2 is installed on the upper end of the loading seat 1 through the spring 3.

Embodiment 2

[0015] When in use, the present invention is first placed on the workbench, and then the load is placed on the upper end of the loading platform 2 after being leveled by the horizontal adjustment screw 7, and the loading platform 2 is moved downward by the gravity of the load, and the compression spring 3 The pressure received by the loading seat 1 is buffered, which greatly buffers the interaction force between the loading platform 2 and the loading seat 1. At the same time, the elastic suction pad 4 at the lower end of the loading seat 1 also moves downward until the elastic suction pad 4 and the loading The seat 1 is sucked together, so that the loading platform 2 and the workbench are fixed together, and finally the loading is fixed by the fixing screw 6 on the positioning block 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com