New vegetable fermentation production method

A production method and vegetable technology, applied in the directions of bacteria, food science, and application used in food preparation, can solve the problems of inability to produce flavor, single flora, and uniqueness, and achieve shortened fermentation time, good product quality, and flavor. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

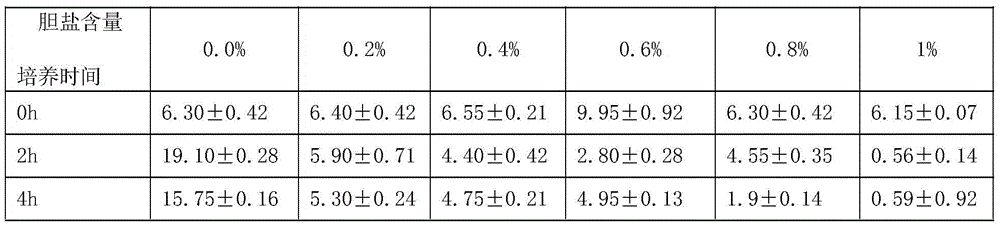

Embodiment 1

[0046] The main steps of the present invention include: adding the kimchi production container after cleaning the vegetables, adding the kimchi fermentation liquid according to 40% of the mass of the vegetable raw materials, a mixture bag of salt and spices with 2% of the mass of the vegetable raw materials, and sealing the container; controlling the temperature at 24-26°C Carry out 8 hours of fermentation; then add 0.6% of the vegetable raw material mass of Lactobacillus plantarum CGMCC11763 bacterial powder to control the temperature of 6 ~ 7 ° C fermentation for 18 hours of fermentation; after fermentation, seasoning: take out kimchi, add mixed seasoning, and then vacuum pack and refrigerate Sales.

[0047] The spice mix package mainly includes peppercorns, star anise, kaempferia, papaya or other spices;

[0048] Mixed seasonings include garlic, paprika, fresh ginger, monosodium glutamate or other seasonings;

[0049] The kimchi fermentation liquid is prepared with referen...

Embodiment 2

[0051] Embodiment 2 is basically the same as Example 1

[0052] The main steps of the present invention include: adding the kimchi production container after cleaning the vegetables, adding the last kimchi fermentation liquid according to 50% of the quality of the vegetable raw materials, a mixture bag of salt and spices with 1% of the quality of the vegetable raw materials, and sealing the container; controlling the temperature at 28°C Carry out 6 hours of fermentation; then add 2% of the vegetable raw material mass of Lactobacillus plantarum CGMCC11763 bacterial powder to control the temperature of 7 ~ 8 ° C fermentation for 15 hours; after fermentation, seasoning: take out kimchi, add mixed seasoning, and then vacuum pack and refrigerate Sales.

[0053] The spice mix package mainly includes peppercorns, star anise, kaempferia, papaya or other spices;

[0054] Mixed seasonings include garlic, paprika, fresh ginger, monosodium glutamate or other seasonings;

[0055] The kim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com