Two-dimensional oscillation of a continuous casting mould

A technology of mold and continuous casting machine, applied in the field of mold (also known as continuous casting mold) oscillation, can solve the problems of high complexity and difficult to use, and achieve the effect of effective lubrication and improved lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

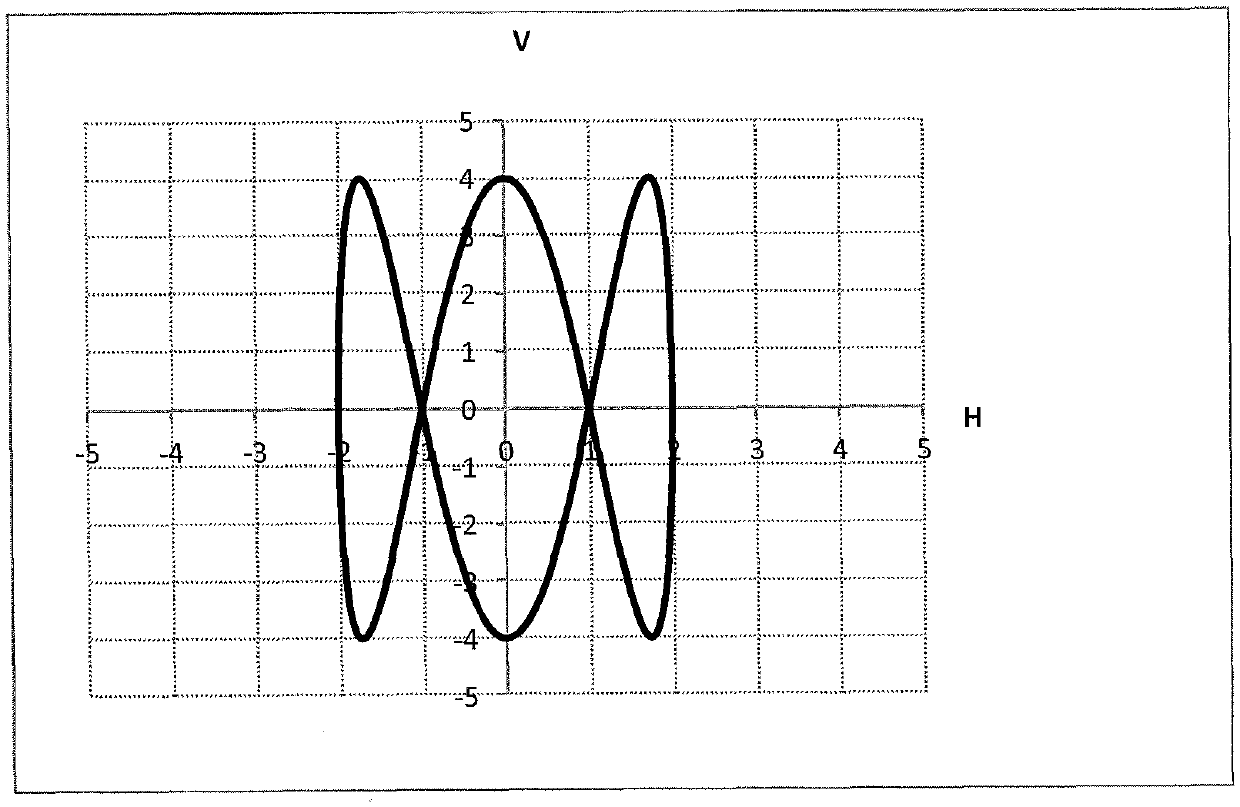

[0042] exist figure 1 shows the trajectory curve (also referred to as motion trajectory) with respect to the broad side of a vertically oscillating mold according to the prior art during one-dimensional oscillation. It can be seen directly from the trajectory curve that the direction of movement of the mold—and thus also of the broad side plates—reverses correspondingly in the top dead center OT and in the bottom dead center; moreover, v≡0 holds true for the velocity v of the mold in the two dead centers OT and UT. Furthermore, the acceleration of the mold in the dead points OT and UT has exactly a maximum value (if for example s=A.sin(ω.t) holds for a displacement s along the vertical y direction), then For the velocity v and the acceleration a, apply v= =A.ω.cos(ω.t) and a= =-A.ω 2 .sin(ω.t). By having │a│=A.ω in the dead points OT and UT 2 Due to the higher acceleration a and the higher friction associated therewith: the strand shell or the casting powder which is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com