Array base plate, preparation method thereof and display panel

A technology of array substrate and base substrate, which is applied in the fields of display panel, its preparation and array substrate, and can solve problems such as defectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

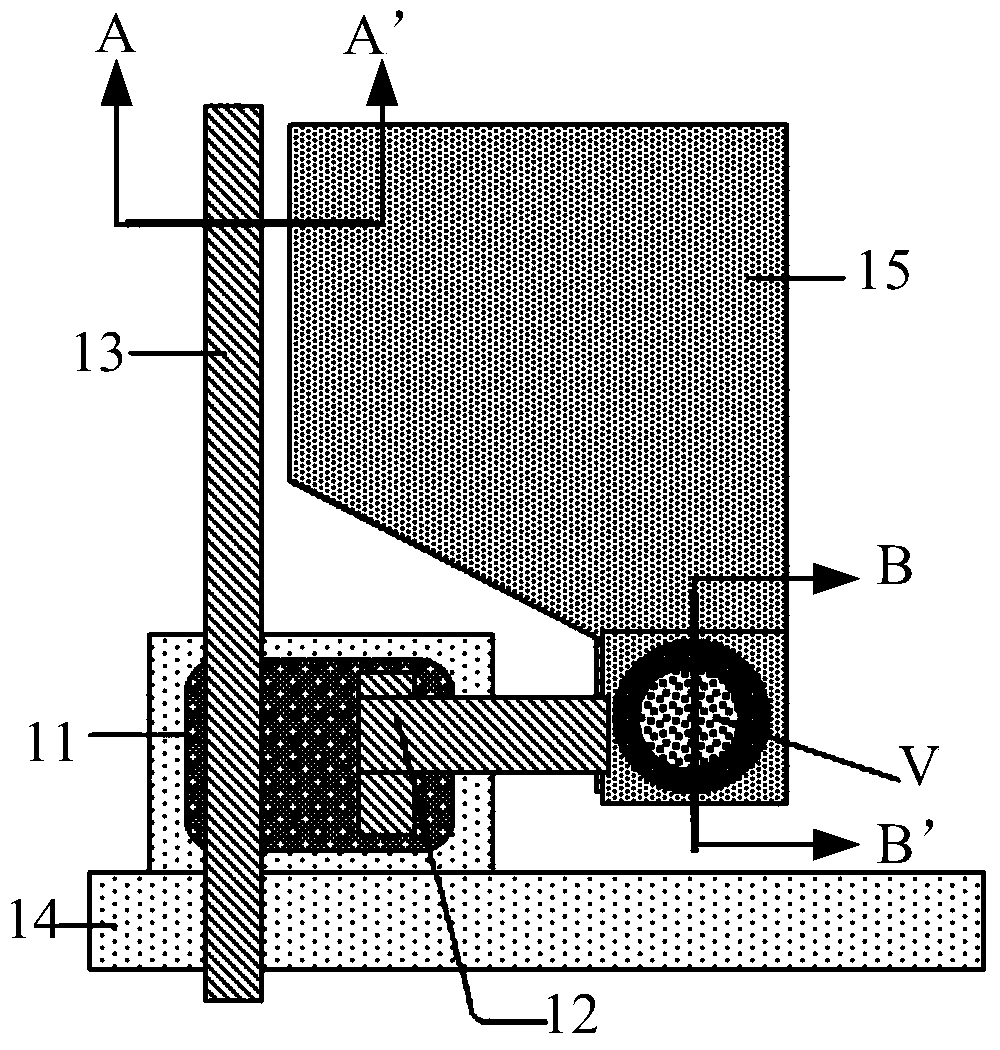

[0062] Based on the same inventive concept, an embodiment of the present invention also provides a method for preparing any one of the above-mentioned array substrates, such as Image 6 As shown, the following steps may be included:

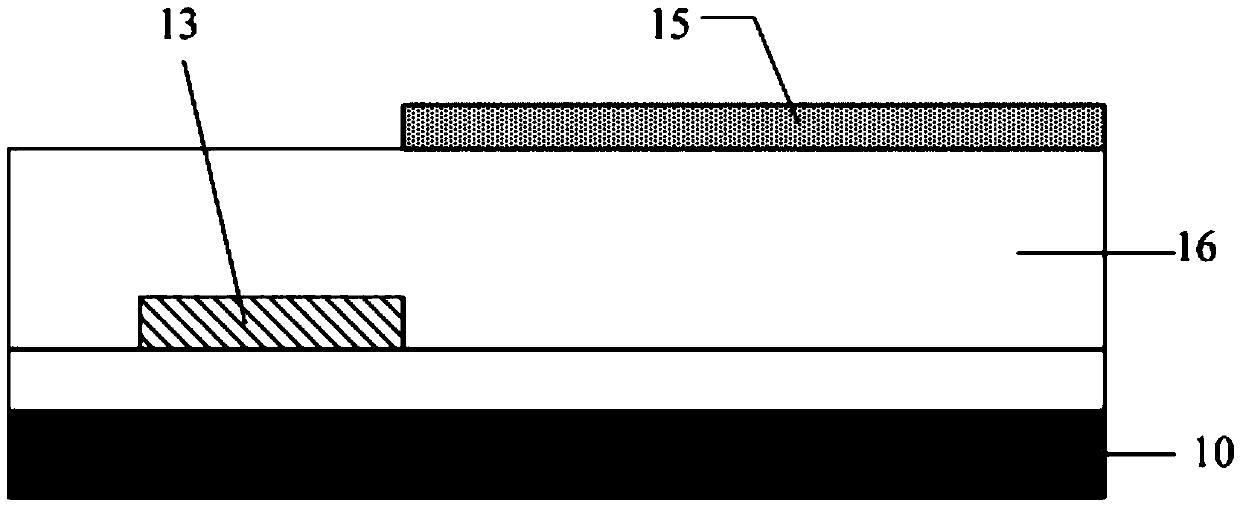

[0063] S601, forming a pattern of the first conductive layer on the base substrate;

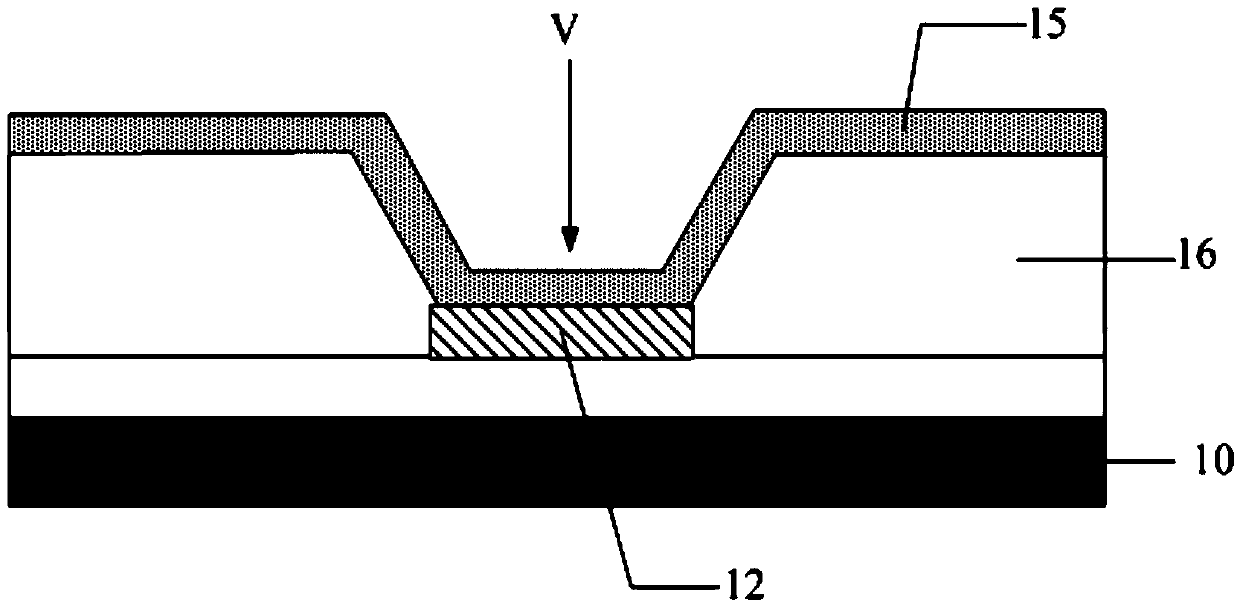

[0064] S602, forming a pattern of an insulating layer on the base substrate formed with the first conductive layer; wherein, the insulating layer has a via area, a semi-reserved area outside the via area, and a pattern surrounding the semi-reserved area and the via area The fully reserved area of the area, the via area is a via hole penetrating the insulating layer, and the vertical distance between the upper surface of the semi-reserved area of the insulating layer and the upper surface of the first conductive layer is smaller than the upper surface of the fully reserved area of the insulating layer the vertical distance from the upper surface of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com