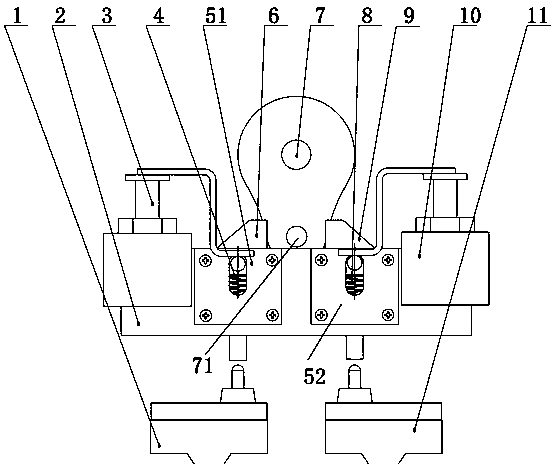

Single-motor three-station actuator and mechanical locking protection device thereof

An operating mechanism and mechanical locking technology, applied in the direction of air switch components, etc., can solve the problems of ineffective protection of the switch body and low debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

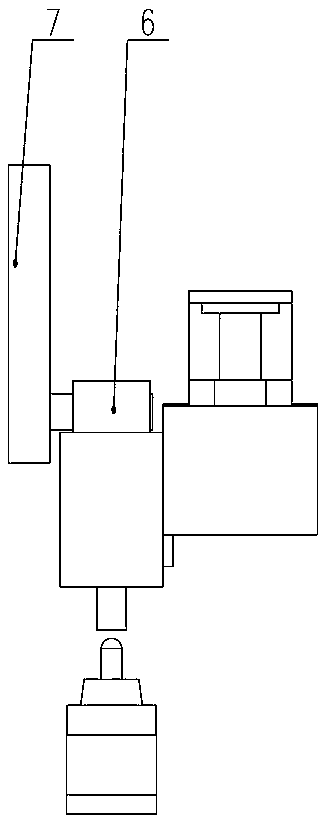

Method used

Image

Examples

Embodiment 2

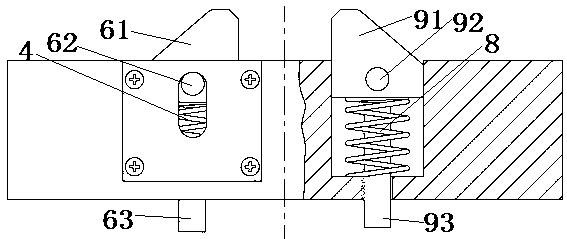

[0031] Embodiment 2: the difference between this embodiment and embodiment 1 is only: as Figure 5 , Figure 6 As shown, the baffle is not provided with a long waist hole, the guide shaft of the baffle is set at the end in contact with the travel switch, the notch of the square groove on the support block is provided with a pair of relative limit ribs, and the automatic return spring When installed in the square groove, the automatic return spring under the limit of the limit convex edge has a certain pre-compression force. Other parts of the implementation are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com