Circular shielding control towline cable and production method thereof

A towline cable, circular technology, applied in the field of circular shielded control towline cable and its preparation, can solve the problem of limited service life, bending resistance and tear resistance, and the integrity of wires and cables cannot be guaranteed and affected. The physical and electrical performance of the cable can be solved to achieve the effect of good structural integrity of the wire and cable, uniform internal and external forces, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

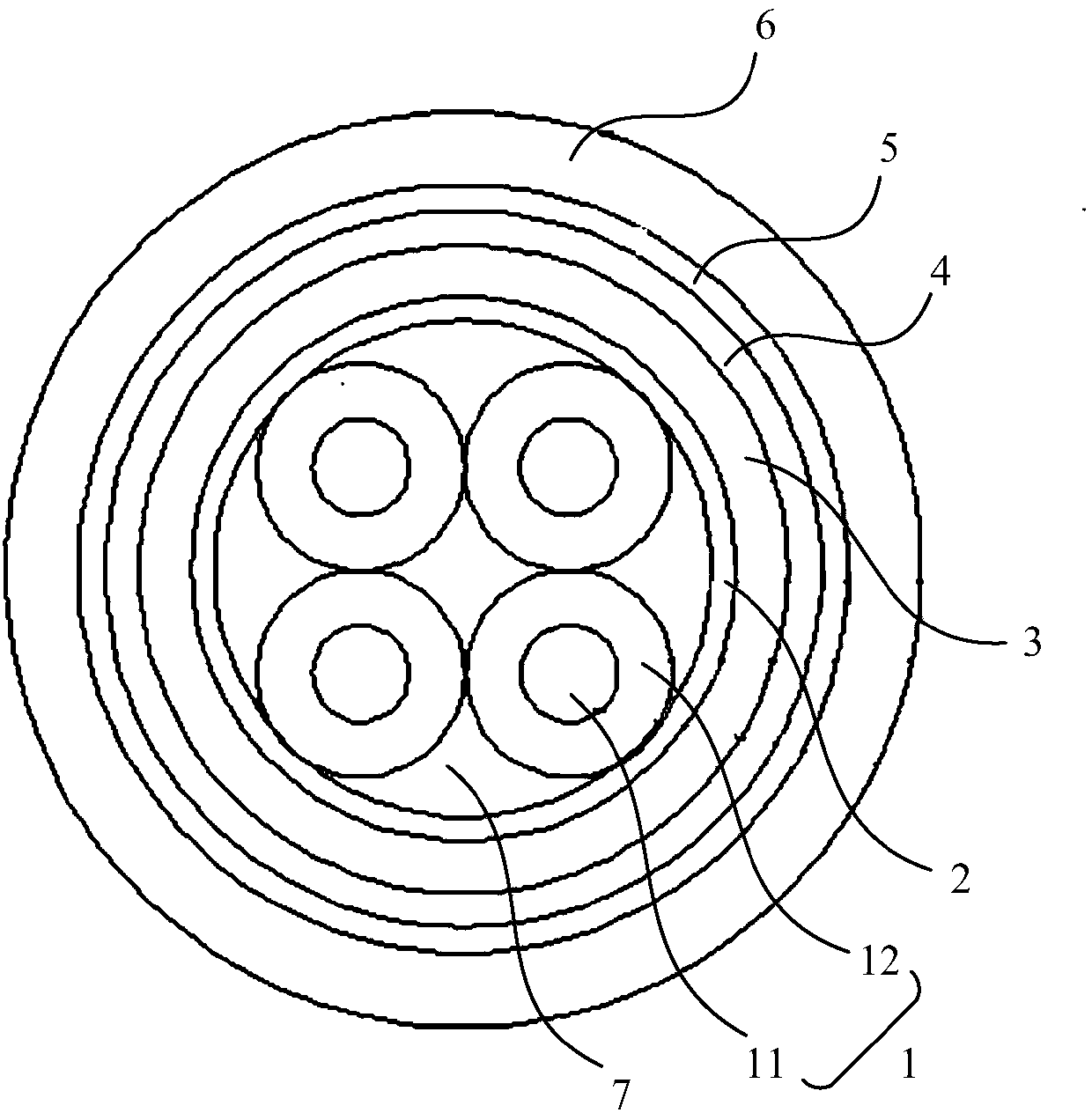

[0027] Aiming at the shortcomings of the circular shielded control towline cable in the prior art, such as poor integrity, easy looseness, insufficient bending resistance, and relatively short life, the present invention provides a circular shielded control towline cable and its preparation The method is to wrap a layer of the first wrapping layer made of fiber paper tape on the outside of the wire core, which has a good fixing effect on the wire core twisted with multiple insulated wire cores, and can ensure that the wire core is The core becomes a whole to ensure that the insulated core is not scattered and prolong the service life of the wire and cable; by adding a second wrapping layer made of tissue paper or cotton cloth between the braid and the outer sheath, the braid and the outer sheath can be reduced. The internal resistance when bending and moving between the outer sheaths, so as to ensure that the internal and external forces of the wire and cable are uniform, there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com