Concrete strain meter having temperature sensing function

A temperature sensor and concrete technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurately obtaining the stress and strain data of concrete structures and large data deviations, so as to improve accuracy and reliability, facilitate temperature compensation, and avoid Effects of Engineering Accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

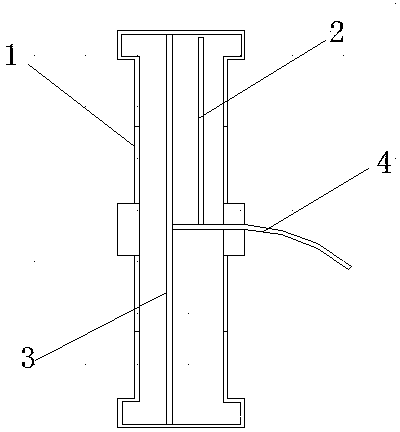

[0008] refer to figure 1 , a new type of concrete strain gauge with temperature sensing function, which includes a housing 1, a temperature sensor 2, a strain sensor 3, and a cable 4, the housing 1 is provided with a temperature sensor 2, a strain sensor 3, and the middle of the housing 1 is provided with The cable 4 is connected with the temperature sensor 2 and the strain sensor 3 .

[0009] The present invention adds a temperature sensor inside the ordinary concrete strain gauge, and the temperature sensor and the strain sensor transmit the measured data to the outside through the cable, because a temperature sensor is set, so that the stress inside the concrete structure can be measured The strain data is measured at the same time as the temperature data. After the two data are transmitted to the technicians, the technicians compensate the stress and strain data according to different temperatures, thereby improving the accuracy of the stress and strain monitoring data ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com