Environmentally friendly discharge treatment system for industrial waste liquid

A treatment system and waste liquid technology, applied in the direction of emission prevention, combustion product treatment, combustion method, etc., can solve the problems of surrounding soil environment, atmospheric environment damage, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

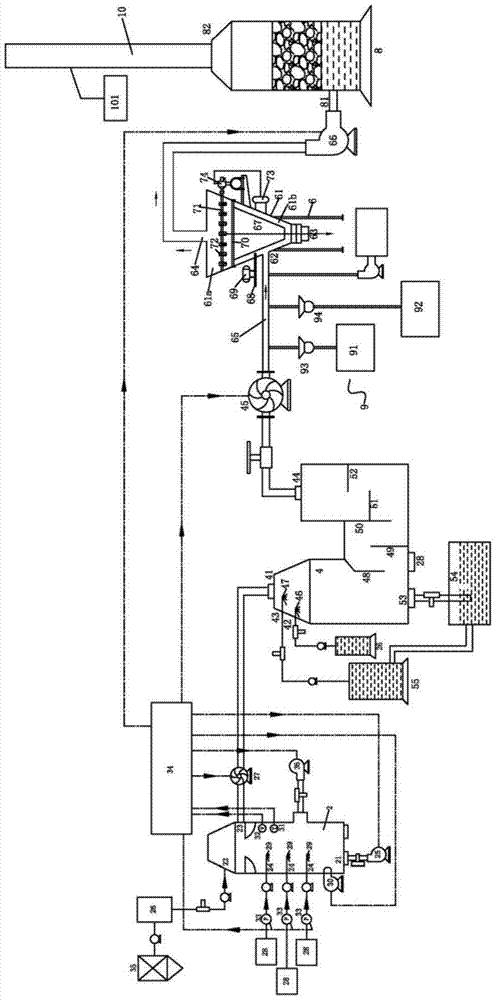

[0035] Such as figure 1 As shown, this embodiment discloses an environmentally friendly discharge treatment system for industrial waste liquid, including a combustion furnace 2, a quenching neutralization absorption tower 4, a deacidification adsorption device 9, a bag dust removal device 6, and a water cycle deacidification and dust removal system arranged in sequence. Scrubber 8 and chimney 10.

[0036] The high-temperature combustion of the waste liquid is completed in the combustion furnace 2. The waste liquid sprayed in the form of mist fully contacts the high-temperature rotating and rising smoke in the combustion furnace. The water in the waste liquid is heated and evaporated, and most of the waste liquid is poisonous. Hazardous substances are completely burned at high temperature, and a large amount of smoke, CO2, and various corresponding acid gases are produced when they are burned out. By adjusting the combustion environment in the combustion chamber, the generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com