Frequency-conversion-type automatic constant-pressure water supplying system and method

A technology of automatic water supply and control system, applied in water supply pipeline system, pump control, water supply device, etc., can solve problems such as high water pressure, waste of electric energy resources, and inability to guarantee constant pressure water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

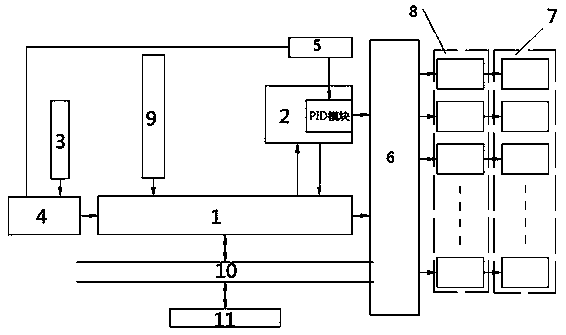

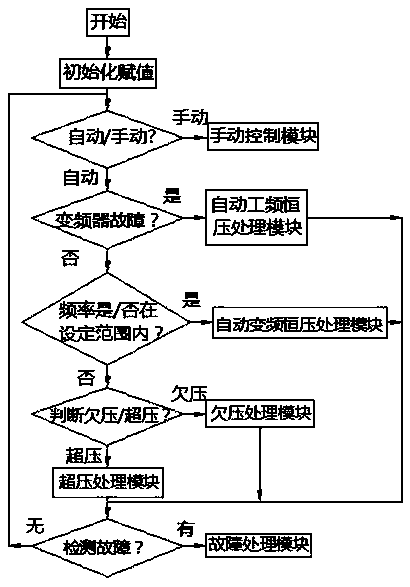

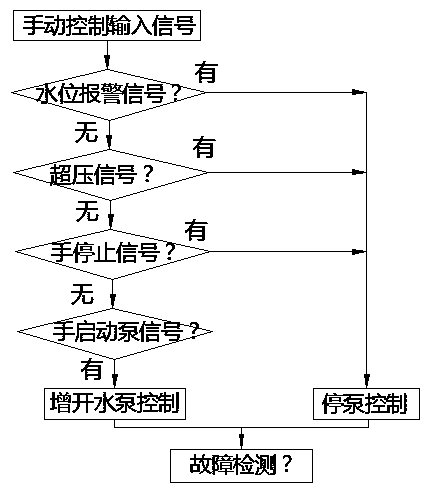

[0074] Embodiment 1: as Figure 1-10 As shown, a variable frequency constant pressure automatic water supply control system includes PLC1, frequency converter 2, liquid level sensor 3, analog output module 4, pressure sensor 5, contactor switching circuit 6, water pump 7, motor 8, manual control Module 9;

[0075] The analog output module 4, the frequency converter 2 and the manual control module 9 are connected to the PLC1 respectively, the output signal detected by the liquid level sensor 3 is connected to the analog output module 4, and the output signal detected by the pressure sensor 5 is connected to the analog output signal respectively. The output module 4 is connected to the PID module of the inverter 2, the PLC1 and the PID module of the inverter 2 are respectively connected to the contactor switching circuit 6, the contactor switching circuit 6 is connected to the motor 8, and the motor 8 drives the water pump 7 to run and supply water.

[0076] It also includes a ...

Embodiment 2

[0114] Embodiment 2: as Figure 1-10 As shown, a variable frequency constant pressure automatic water supply control system includes PLC1, frequency converter 2, liquid level sensor 3, analog output module 4, pressure sensor 5, contactor switching circuit 6, water pump 7, motor 8, manual control Module 9;

[0115] The analog output module 4, the frequency converter 2 and the manual control module 9 are connected to the PLC1 respectively, the output signal detected by the liquid level sensor 3 is connected to the analog output module 4, and the output signal detected by the pressure sensor 5 is connected to the analog output signal respectively. The output module 4 is connected to the PID module of the inverter 2, the PLC1 and the PID module of the inverter 2 are respectively connected to the contactor switching circuit 6, the contactor switching circuit 6 is connected to the motor 8, and the motor 8 drives the water pump 7 to run and supply water.

[0116] A frequency convers...

Embodiment 3

[0153] Embodiment 3: as Figure 1-10 As shown, a variable frequency constant pressure automatic water supply control system includes PLC1, frequency converter 2, liquid level sensor 3, analog output module 4, pressure sensor 5, contactor switching circuit 6, water pump 7, motor 8, manual control Module 9;

[0154] The analog output module 4, the frequency converter 2 and the manual control module 9 are connected to the PLC1 respectively, the output signal detected by the liquid level sensor 3 is connected to the analog output module 4, and the output signal detected by the pressure sensor 5 is connected to the analog output signal respectively. The output module 4 is connected to the PID module of the inverter 2, the PLC1 and the PID module of the inverter 2 are respectively connected to the contactor switching circuit 6, the contactor switching circuit 6 is connected to the motor 8, and the motor 8 drives the water pump 7 to run and supply water.

[0155] It also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com