Washing machine filtering assembly and washing machine

A filter assembly and washing machine technology, applied in the field of washing machines, can solve the problems of short service life, troublesome cleaning and replacement, large space occupation, etc., and achieve the effect of solving lint fouling and facilitating online cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

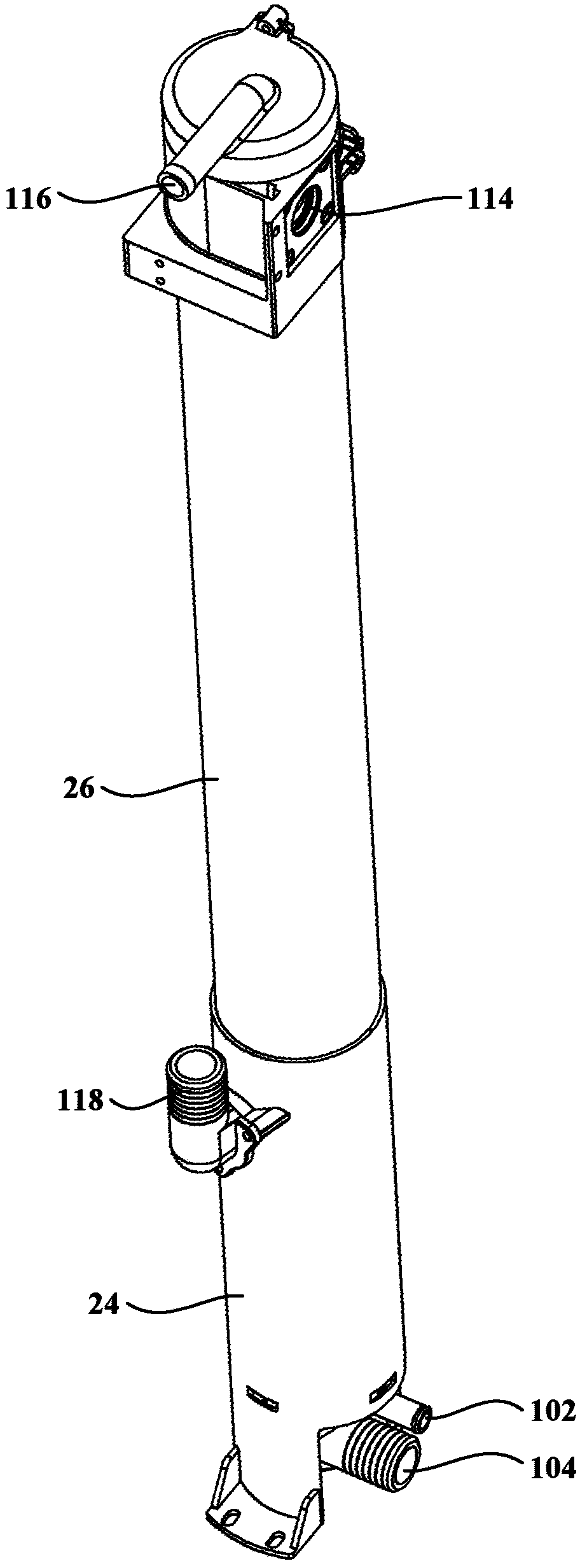

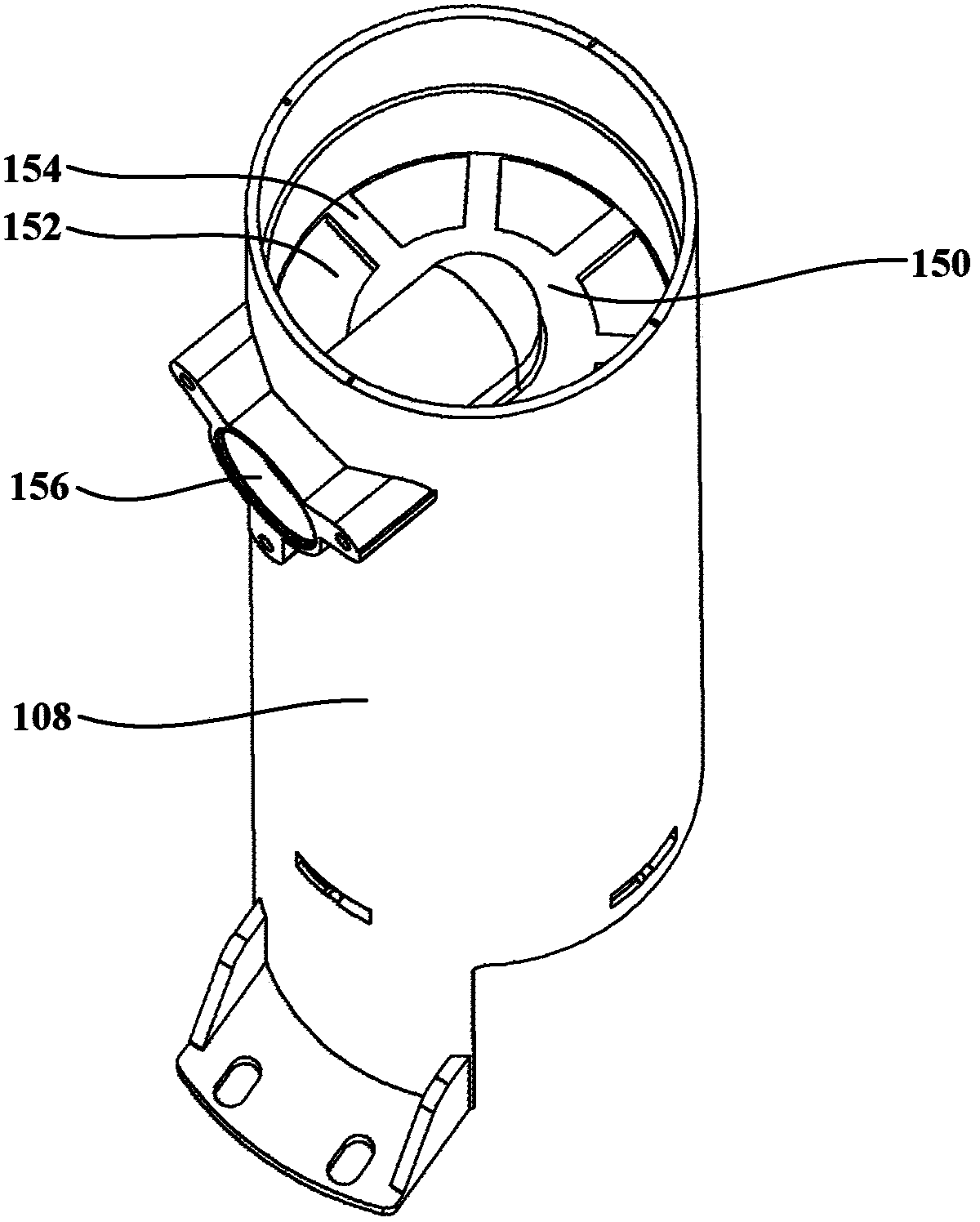

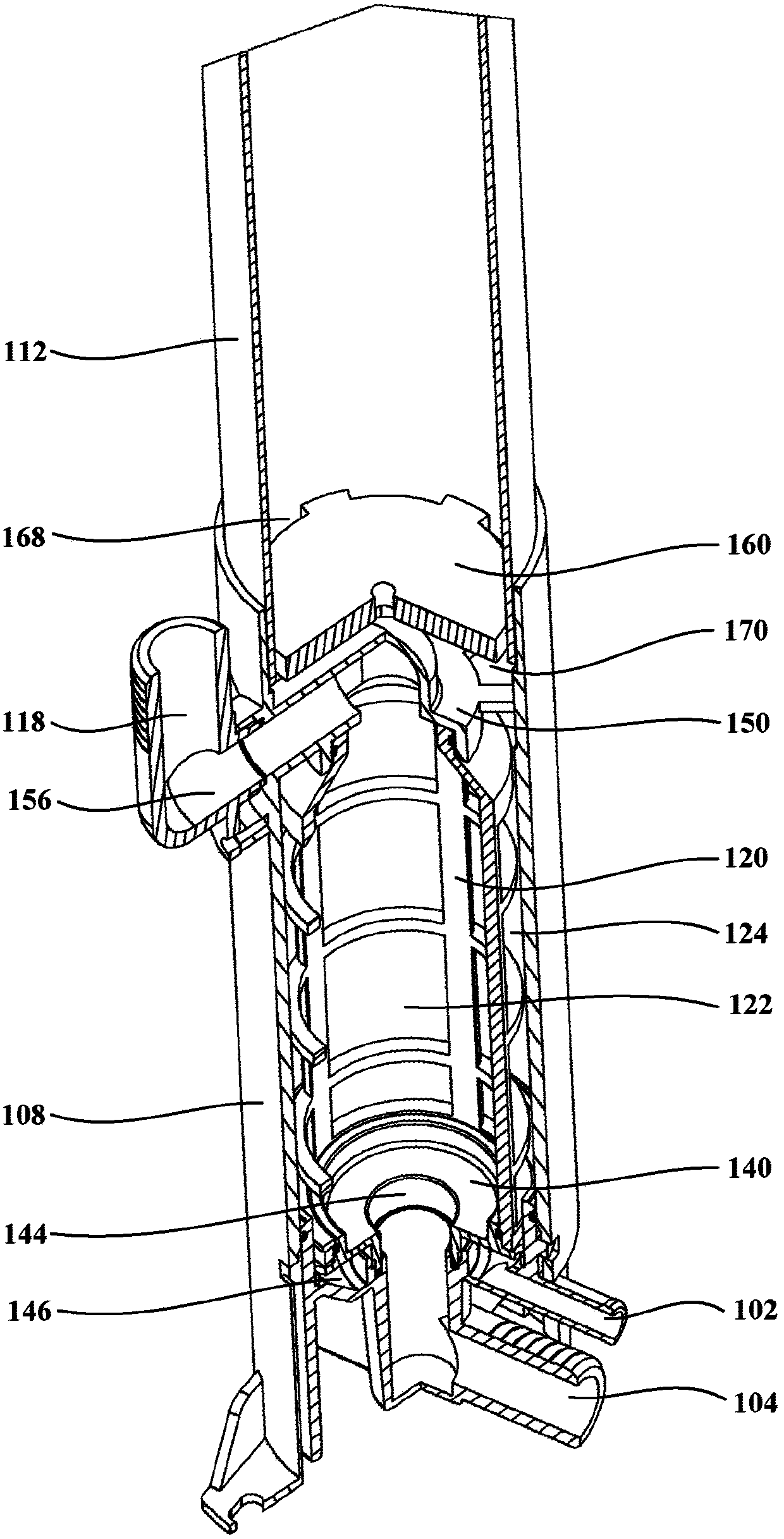

[0049] see Figure 1-Figure 3 , the filter assembly used in the washing machine in the embodiment of the present invention may include a pre-filter 24 and a filter membrane assembly 26 . A water and air distribution member 160 is provided in the fluid passage between the filter membrane module 26 and the pre-filter 24, so that the fluid flowing out from the water production port of the pre-filter 24 is diverted by the water and air distribution member 160 and then flows into the filter. Membrane assembly 26.

[0050] The inventors of the present application have found that if the water flowing out from the water production port of the pre-filter 24 directly enters the filter membrane assembly 26, since the water from the water production port of the pre-filter 24 concentrates on the top of the water production port of the pre-filter and enters the filter Membrane module 26 will lead to greater filtration burden in the local area of the membrane filaments inside the filter mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com