A method for preparing metal arsenic block

A technology for metal arsenic and simple arsenic, which is applied in the intersecting fields of metallurgical engineering and environmental engineering, can solve the problems of inefficient and environmentally friendly production, high toxicity of arsenic oxide, and difficulty in storage, so as to eliminate huge safety risks, considerable economic benefits, and sales volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

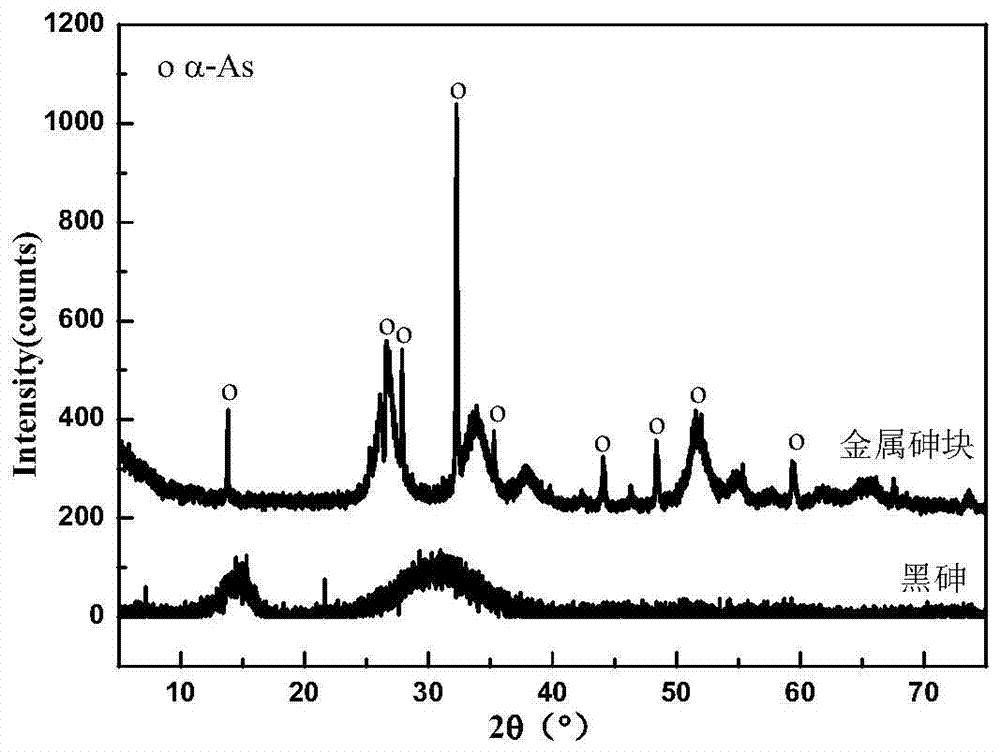

Embodiment 1

[0023] Taking arsenic oxide, an associated product of a non-ferrous smelter in Hunan Province, as raw material, add 10g of arsenic oxide to a 2mol / L hydrochloric acid solution heated to 50°C, and dissolve the arsenic oxide after 0.5h. Add stannous chloride in a molar ratio of n(Sn): n(As) at a ratio of 1. After reacting for 1 hour, filter and wash with black arsenic. After the black arsenic was dried in an oven at 105°C for 4 hours, the polyacrylate was added to the black arsenic at a mass ratio of black arsenic to thermal adhesive of 20:1, mixed and then put into a mold. The thickness of the manufactured module is 0.04m. After the molding is completed, the steel mold is placed in the hot pressing furnace, first pressed to 100Mpa and maintained at the pressure, and then the temperature is rapidly increased to 400°C, and the hot pressing reaction is performed for 1 hour. After the hot pressing is completed, the steel mold is taken out, and the metal arsenic block is obtained aft...

Embodiment 2

[0025] Using arsenic oxide, an associated product of a non-ferrous smelter in Hunan, as raw material, 10g of arsenic oxide was added to a 5mol / L hydrochloric acid solution heated to 70°C, and the arsenic oxide was completely dissolved after 0.5h. Stannous chloride was added in a molar ratio of n(Sn): n(As) at a ratio of 1.2. After the reaction for 1.5 hours, black arsenic was obtained by filtering and washing with water. After the black arsenic was dried in an oven at 105°C for 4 hours, polyurethane was added to the black arsenic at a ratio of 50:1 by mass of the black arsenic to the thermal adhesive. The thickness of the module is 0.05m. After the molding is completed, the steel mold is placed in the hot pressing furnace, first press to 150Mpa and maintain the pressure, and then rapidly increase the temperature to 450°C, and react with hot pressing for 1 hour. After the hot pressing is completed, the steel mold is taken out, and the metal arsenic block is obtained after natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com