Anti-bacterial and anti-mildew cleaning treatment agent for communication facilities and preparation method of anti-bacterial and anti-mildew leaning treatment agent

A communication facility and anti-mildew technology, applied in the field of cleaning agent, can solve the problems of poor cleaning effect, prone to mildew, no antibacterial, etc., and achieve the effect of strong cleaning ability, low cleaning cost and strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

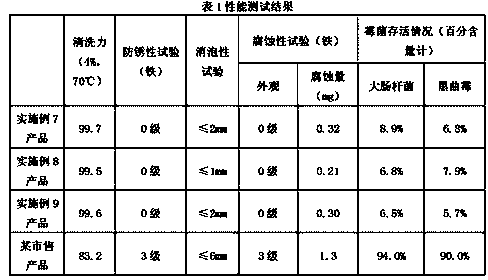

Examples

Embodiment 1

[0019] Embodiment 1, the raw materials of the antibacterial and mildew-proof cleaning treatment agent for communication facilities include 50 to 54 parts of primary alcohol polyoxyethylene ether, 52 to 56 parts of sodium petroleum sulfonate, didecyl dimethyl 48 to 52 parts of ammonium chloride, 52 to 56 parts of sucrose fatty acid ester, 48 to 52 parts of tert-butyl hydroxyanisole, 52 to 56 parts of cetyl dimethyl benzyl ammonium chloride , 48-52 parts of octylphenol polyoxyethylene ether, 54-58 parts of sodium hypochlorite, 48-52 parts of 2-ethylhexyl sulfosuccinate, 48-52 parts of tartaric acid, 52-56 parts of oxalic acid 48 to 52 parts of stearic acid monoglyceride, 52 to 56 parts of peppermint essential oil, 48 to 52 parts of ethoxylated nonylphenol ether, 52 to 56 parts of alkyl ether amine oxide, 48 parts of tetrachloroethylene 52 to 52 parts, 48 to 52 parts of sodium nitrite, 52 to 56 parts of zinc epoxy acid, 48 to 52 parts of chitin, 52 to 56 parts of carbendazim, 4...

Embodiment 2

[0020] Embodiment 2, the raw materials of the antibacterial and mildew-proof cleaning treatment agent for communication facilities include 50 parts or 54 parts of primary alcohol polyoxyethylene ether, 52 parts or 56 parts of sodium petroleum sulfonate, didecyl dimethyl 48 or 52 parts of ammonium chloride, 52 or 56 parts of sucrose fatty acid ester, 48 or 52 parts of tert-butyl hydroxyanisole, 52 or 56 parts of cetyl dimethyl benzyl ammonium chloride , 48 or 52 parts of octylphenol polyoxyethylene ether, 54 or 58 parts of sodium hypochlorite, 48 or 52 parts of 2-ethylhexyl sulfosuccinate, 48 or 52 parts of tartaric acid, 52 or 56 parts of oxalic acid 48 or 52 parts of stearic acid monoglyceride, 52 or 56 parts of peppermint essential oil, 48 or 52 parts of ethoxylated nonylphenol ether, 52 or 56 parts of alkyl ether amine oxide, 48 parts of tetrachloroethylene or 52 parts, 48 or 52 parts of sodium nitrite, 52 or 56 parts of zinc epoxy acid, 48 or 52 parts of chitin, 52 or 56...

Embodiment 3

[0021] Embodiment 3, as the optimization of above-mentioned embodiment, the raw material of antibacterial anti-mildew cleaning treatment agent primary of communication facilities comprises 52 parts of alcohol polyoxyethylene ethers, 54 parts of petroleum sodium sulfonates, didecyl dimethyl 50 parts of ammonium chloride, 54 parts of sucrose fatty acid ester, 50 parts of tert-butyl hydroxyanisole, 54 parts of cetyl dimethyl benzyl ammonium chloride, 50 parts of octylphenol polyoxyethylene ether, sodium hypochlorite 56 parts, 50 parts of 2-ethylhexyl sulfosuccinate, 50 parts of tartaric acid, 54 parts of oxalic acid, 50 parts of hard resinous monoglyceride, 54 parts of peppermint essential oil, 50 parts of ethoxylated nonylphenol ether, 54 parts of base ether amine oxide, 50 parts of tetrachlorethylene, 50 parts of sodium nitrite, 54 parts of zinc epoxy acid, 50 parts of chitin, 54 parts of carbendazim, 50 parts of chlorothalonil, 15000 parts of water, alkanolamide 54 parts and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com