A kind of preparation method of fully water-soluble solid ammonium polyphosphate

A kind of ammonium polyphosphate, water-soluble technology, applied in chemical instruments and methods, phosphate fertilizers, phosphorus compounds, etc., can solve the problems of phosphorus resource value not reflected, high storage and transportation costs, concentration, long polymerization time, etc., to achieve convenience Transportation and subsequent use, reduced transportation costs, and good subsequent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

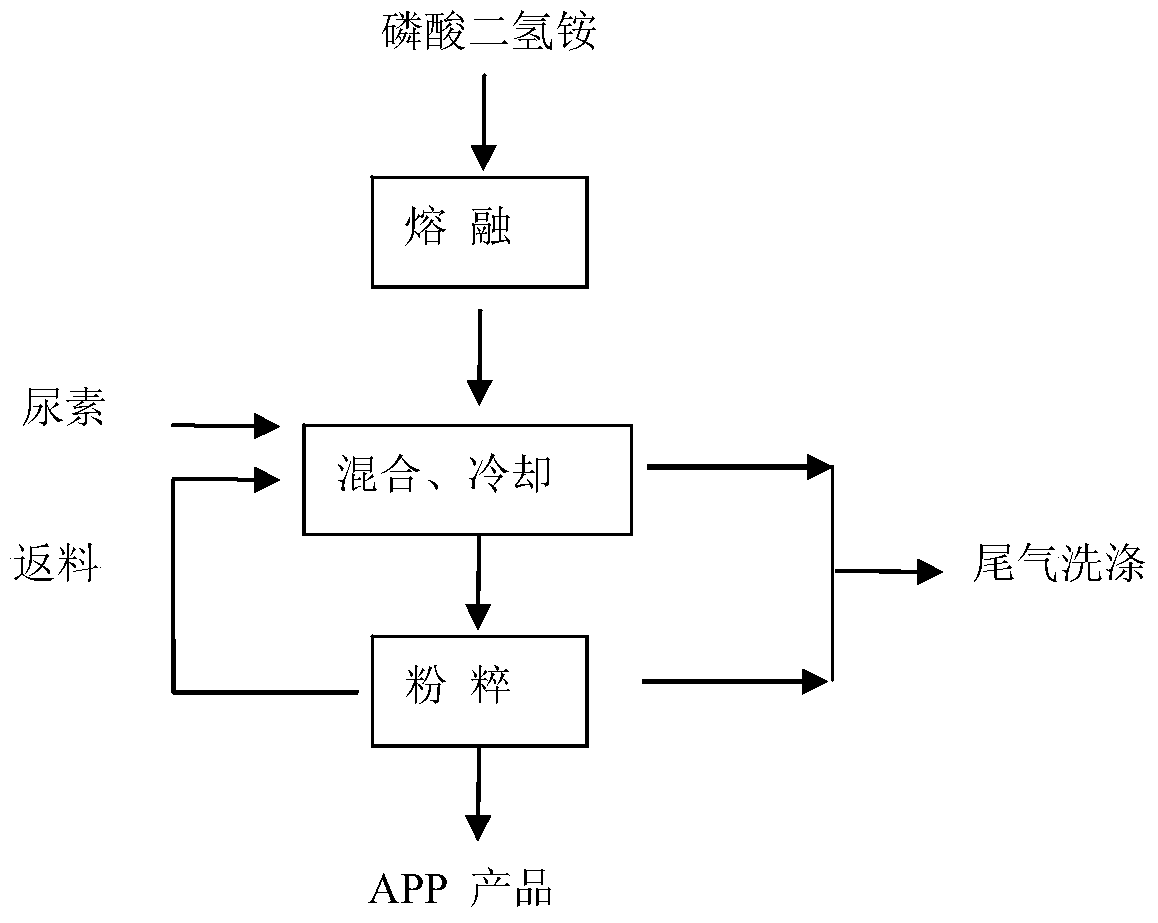

[0026] The preparation method of water-soluble solid ammonium polyphosphate of the present invention can be implemented in the following steps:

[0027] a. Melt ammonium dihydrogen phosphate at 190-350°C and keep it for 10-60 minutes to obtain molten slurry;

[0028] b. Add the molten slurry obtained in step a into the reaction vessel, then add urea to stir and react to obtain the reaction slurry, then add the reaction slurry to the water-soluble solid ammonium polyphosphate and stir at the same time, and the reaction is completed to obtain a polymerized cured product , the temperature of the reaction system is controlled at not higher than 80°C during the reaction;

[0029] c. Crushing and packaging: pulverize the polymerized and solidified material obtained in step b, and seal and package to obtain water-soluble solid ammonium polyphosphate.

[0030] In actual operation, you can first add urea into the molten slurry to react, and stir to defoam to obtain a reaction slurry w...

Embodiment 1

[0031] Embodiment one uses the inventive method to prepare ammonium polyphosphate

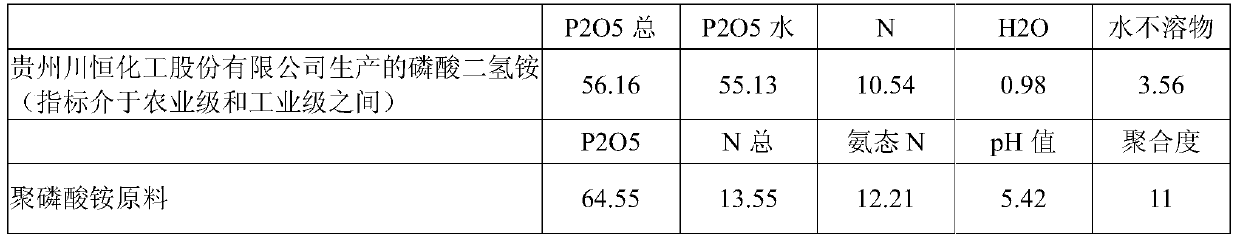

[0032] Ammonium dihydrogen phosphate with a nutrient of 66 (11-55-0) is used as a raw material, and the indicators are as shown in Table 1.

[0033] Table 1 raw material composition index (unit: mass %)

[0034]

[0035]Weigh 2000g of the above-mentioned ammonium dihydrogen phosphate, heat it to 200°C in a stainless steel heating vessel with a stirring device to melt, and keep it for 50 minutes to keep the material with good fluidity. According to the calculation of urea: P=0.5 (molar ratio), weigh 475g of urea, slowly add it into the molten ammonium slurry, and control the reaction temperature to 200°C to obtain the reaction slurry. Then weigh about 4120g of powdered ammonium polyphosphate and pour it into a mixer with stirring device. The reaction slurry is dispersed by centrifugal atomization equipment and evenly spread on the ammonium polyphosphate. After the material is cooled, it is ...

Embodiment 2

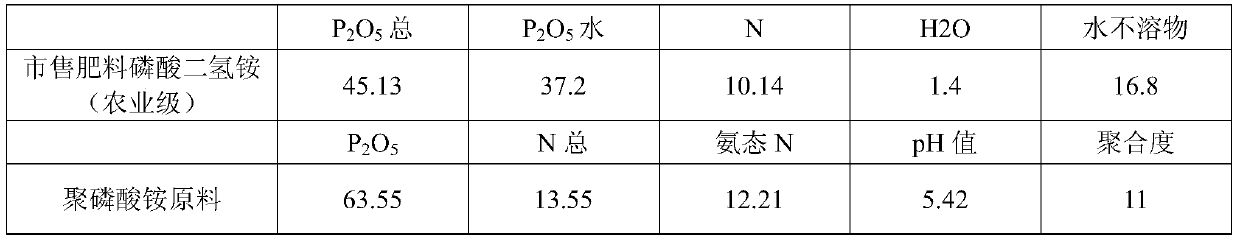

[0036] Embodiment two uses the inventive method to prepare ammonium polyphosphate

[0037] The same monoammonium as in Example 1 was used as a raw material, and the raw material index is shown in Table 1.

[0038] Weigh 2000g of ammonium dihydrogen phosphate, heat it in a stainless steel heating vessel with high-speed stirring at 250°C and melt it, and keep it for 35 minutes, so as to control and keep the material with good fluidity. According to the calculation of urea: P=1.0 (molar ratio), weigh 950g of urea, slowly add it into the molten ammonium slurry, and control the reaction temperature to 250°C to obtain the reaction slurry. Then weigh about 3620g of powdered ammonium polyphosphate and pour it into a mixer with stirring device. The reaction slurry is dispersed by centrifugal atomization equipment and evenly spread on the ammonium polyphosphate. After the material is cooled, it is pulverized to obtain the product. The product has good physical properties, does not abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com