Universal composite bony windscreen wiper

A composite, large bone protection technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve cumbersome problems, reduce installation work, avoid driving risks, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

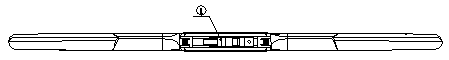

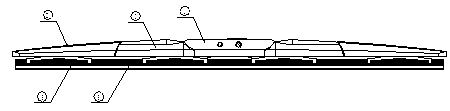

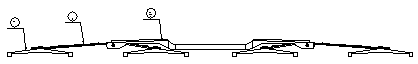

[0016] The device includes a large bone 9, the two ends of the large bone 9 are connected to the middle bone 4 through a plastic rotating shaft, the middle bone 4 is connected to the wing foot 7 through the shaft hole, and the lower end of the wing foot 7 is connected to the rubber strip 6 through the arc-shaped flat wire 5, such as figure 1 , figure 2 , image 3 As shown, the big bone 9 is connected to the big bone guard 3 , both ends of the big bone guard 3 are connected to the side bone guard 2 , and the big bone guard 3 is connected to the multifunctional joint 1 .

[0017] The big bone guard 3 is provided with a buckle, and the buckle on the big bone guard 3 is connected to the big bone 9, and the side bone guard 2 is connected to the middle bone 4 through the hole axis of the big bone guard 3, and the side The bone guard 3 is provided with a buckle connected to the middle bone 4 .

[0018] The design that one joint is suitable for seven kinds of scraper arms solves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com