A large-scale composite tension-compression hydraulic forming machine

A molding machine and hydraulic technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of inability to press and meet industrial production, and achieve the effects of simple operation, convenient and fast movement, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

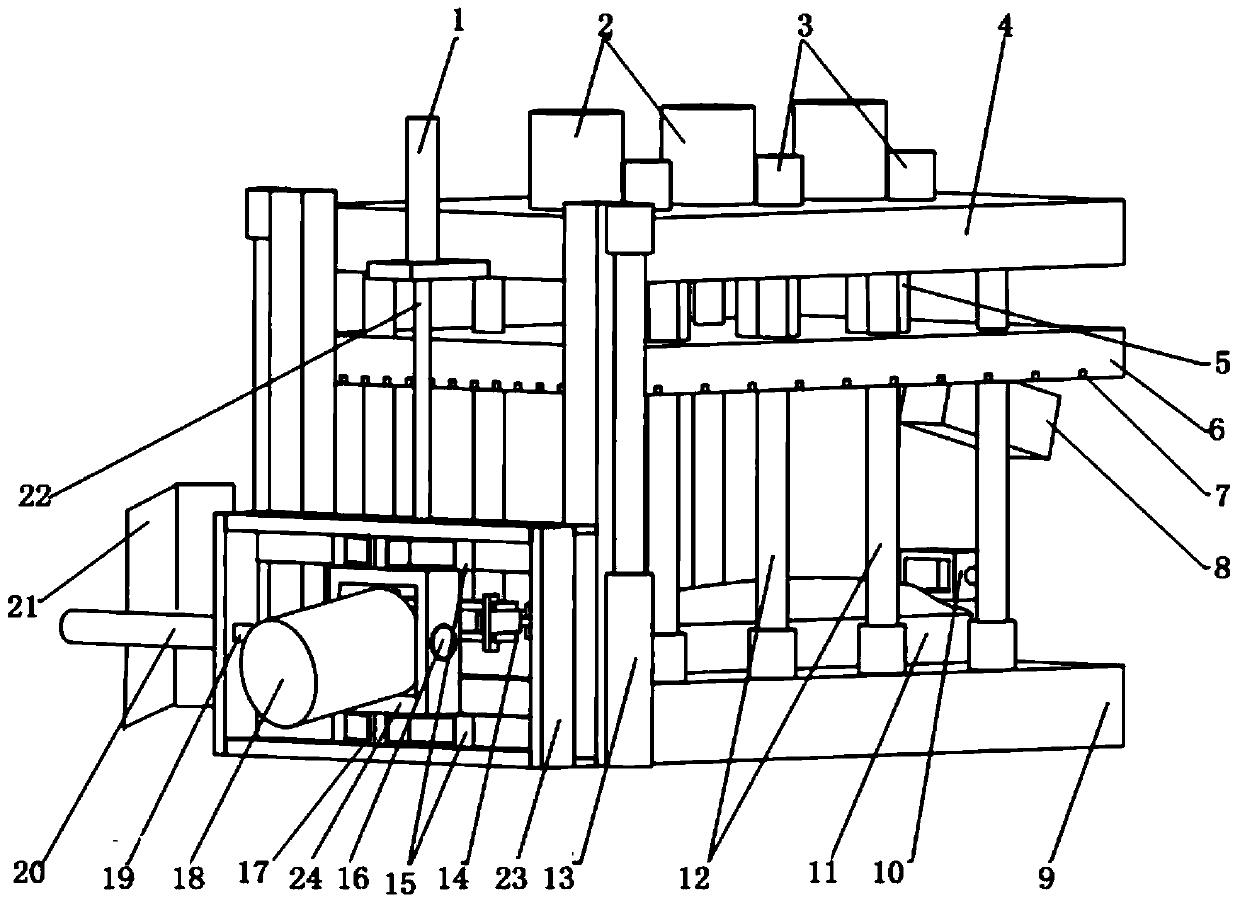

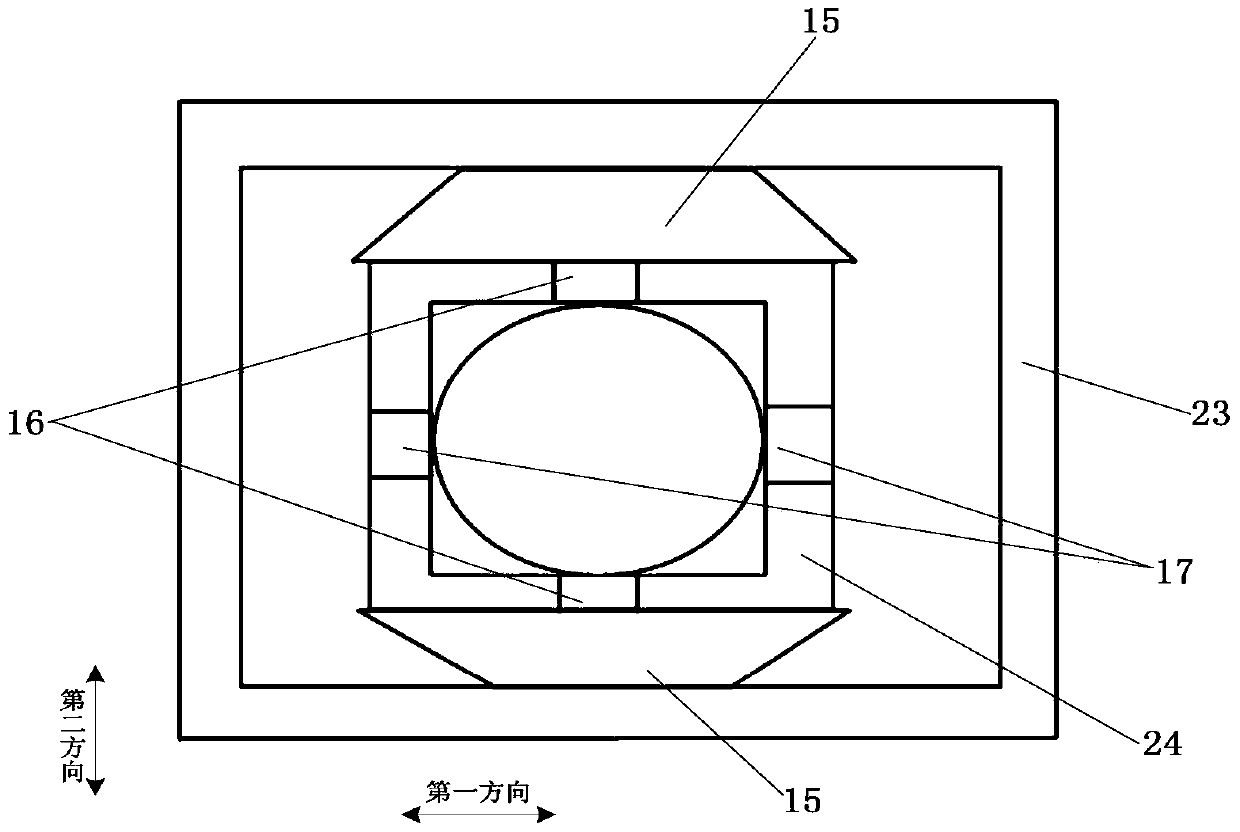

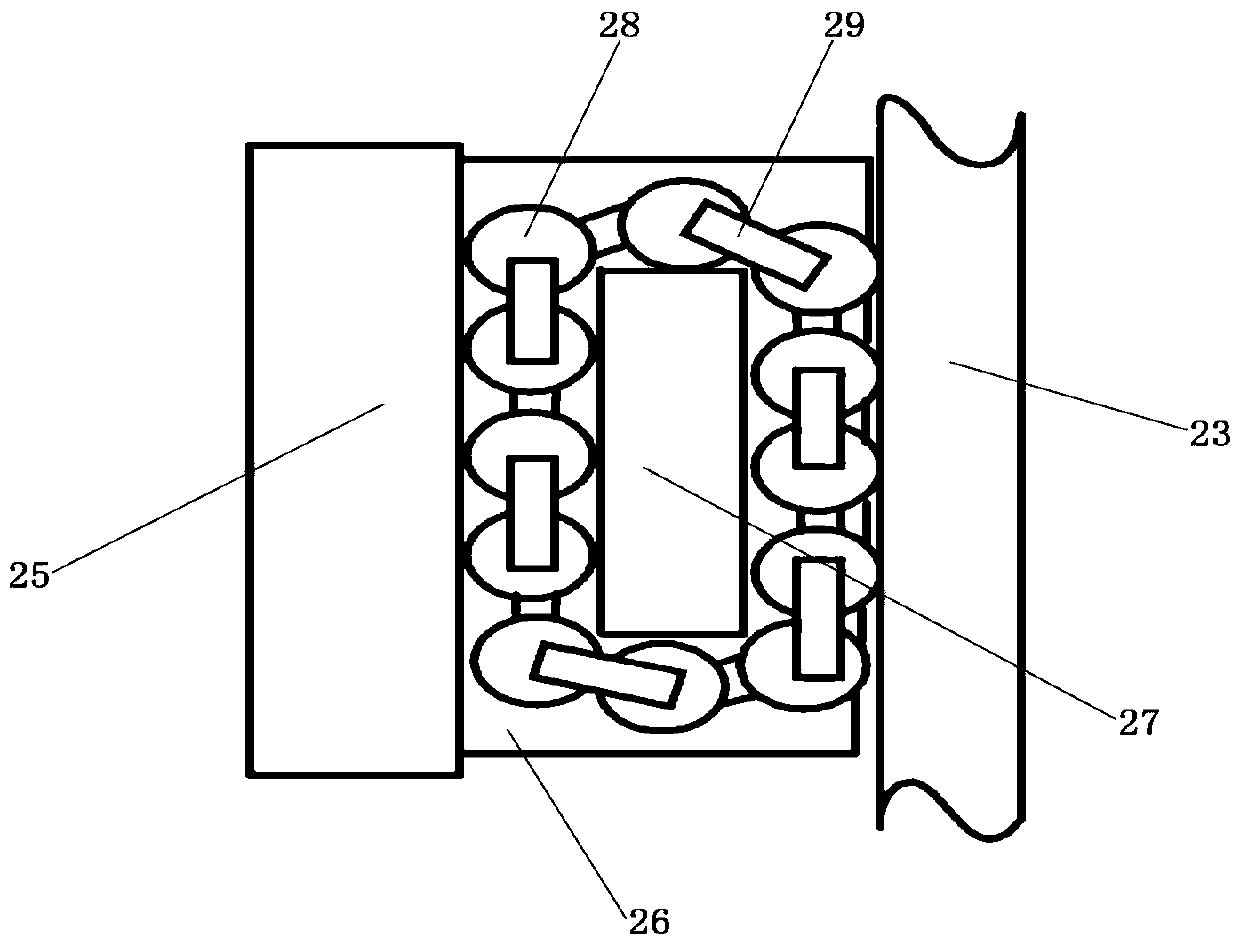

[0025] see Figure 1 to Figure 5 , the embodiment of the present invention provides a large-scale composite tension-compression hydroforming machine, including: upper side hydraulic cylinder 1, upper side hydraulic transmission shaft 22, hydraulic oil tank 2, hydraulic oil pump 3, frame frame 4, frame Positioning column 13, hydraulic transmission shaft sleeve column 5, base 9, tooling fixture 10, forming mold 11, hydraulic positioning column 12, hydraulic platform 6, fixed clamping plate 14, side hydraulic transmission shaft 19, side hydraulic cylinder 20, pull Stretching hydraulic cylinder 18 and control panel 21, wherein, the upper part of the base 9 is provided with a frame-type frame 4, one side of the frame-type frame 4 is provided with a stretching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com