A multi-standard glass door tooling

A glass door, multi-specification technology, used in workbenches, manufacturing tools, hand-held tools, etc., can solve the problems of no correction device, poor assembly reliability, product specification limitations, etc., to reduce defects, high assembly accuracy, and versatility. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

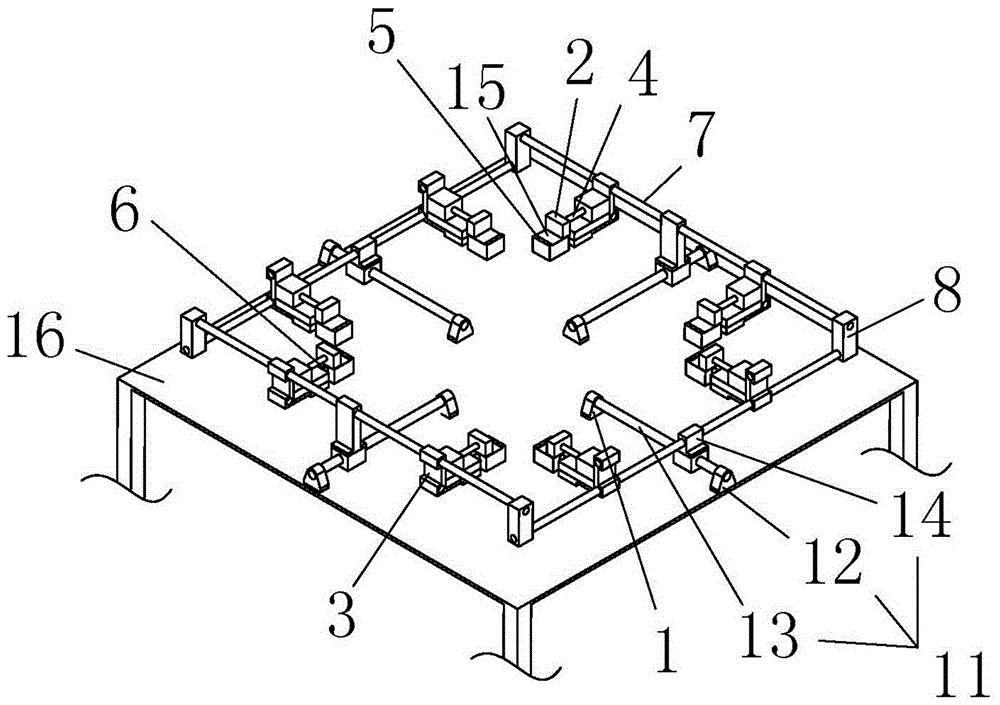

[0034] Embodiment 1: as figure 1As shown, a multi-standard glass door tooling is used for assembling the flat glass of the door frame to make an embedded glass frame door, including a flat glass support part 1 for placing the flat glass, and a flat glass support part 1 arranged on the flat glass The surrounding frame support part 15 that makes the door frame and the flat glass be placed on the same plane also includes a frame support part 15 that is arranged on one side of the frame support part 15 and abuts against the door frame from the outside and makes it point to the displacement of the flat glass to make the door A fastening mechanism with the frame nested around the plate glass, and a correction mechanism that abuts against the inner side of the door frame and makes the door frame move away from the plate glass after the fastening mechanism completes the displacement or movement tendency.

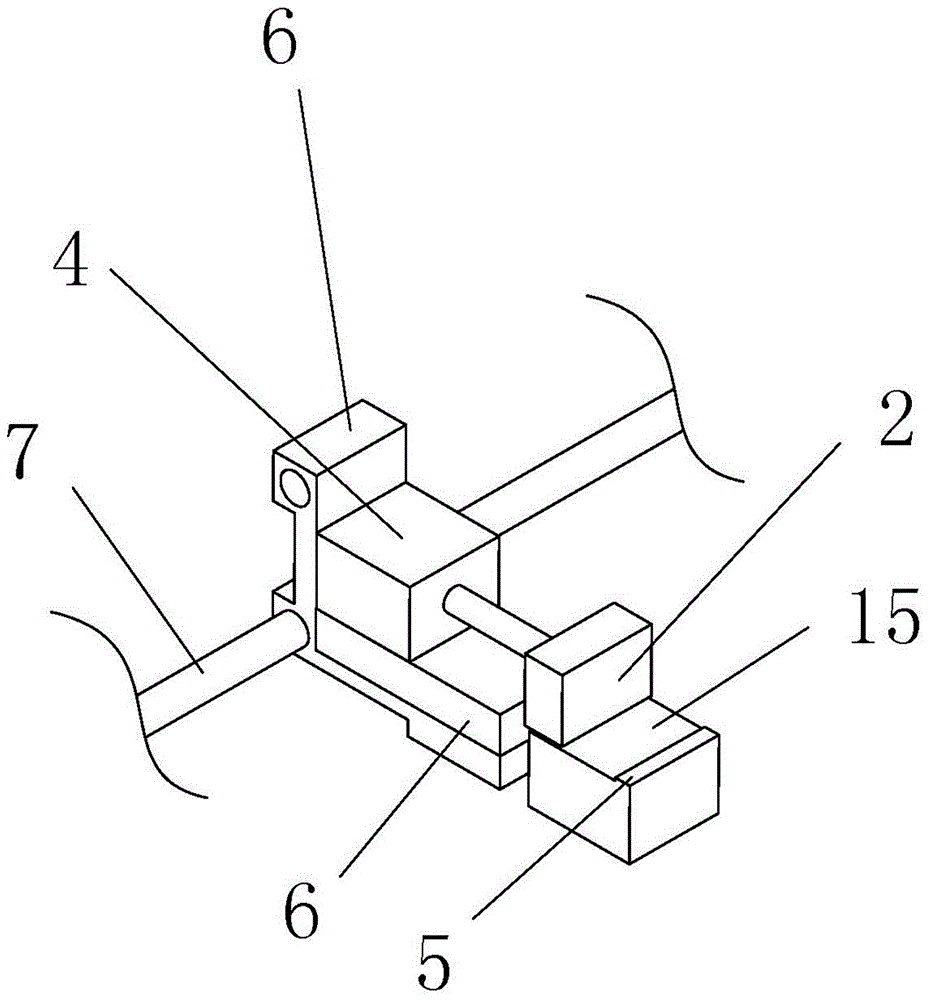

[0035] Such as figure 2 As shown, the fastening mechanism includes a fastenin...

Embodiment 2

[0039] Embodiment 2: The difference between Embodiment 5 and Embodiment 1 is that the guide rail 7 is fixed end-to-end through fixed connectors, and the length of the air rods of the first pneumatic device 4 and the second pneumatic device 6 is used to adjust the fastening structure and the correction mechanism working position; no workbench base 11 is provided.

Embodiment 3

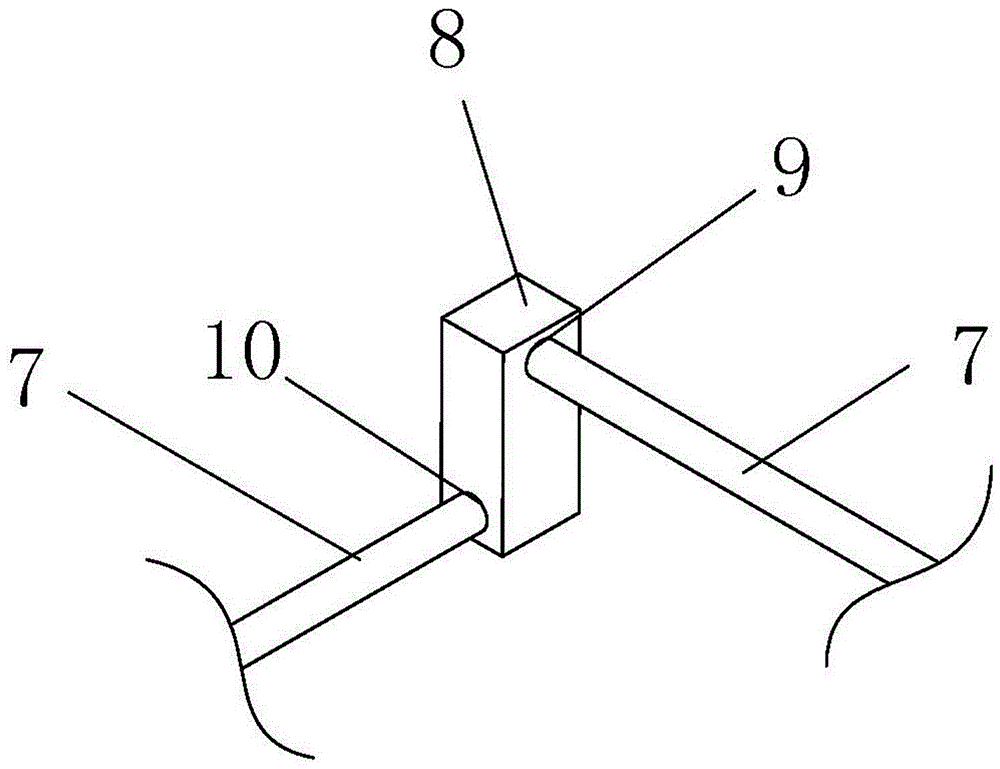

[0040] Embodiment 3: The difference between Embodiment 3 and Embodiment 1 is that the adjustment component 8 is placed directly on the workbench top 16; the fastening structure and the correction mechanism are arranged alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com