Coal-fired flue gas mercury removal adsorbing agent and preparation method and application thereof

A coal-fired flue gas and adsorbent technology, which is applied in the field of coal-fired flue gas mercury removal adsorbent and its preparation, can solve the problems of low adsorption efficiency, narrow action temperature range, and high price, so as to improve adsorption capacity and increase active points , Strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A mercury-removing adsorbent for coal-fired flue gas of the present invention is mainly obtained by modifying the non-carbon-based carrier chabazite with an active material cupric chloride solution.

[0028] A preparation method of the coal-fired flue gas mercury removal sorbent of the above-mentioned present embodiment, comprising the following steps:

[0029] (1) Put the non-carbon-based carrier chabazite into a passivated container, pour a copper chloride solution with a mass concentration of 5wt% into the container to ensure that the solution can fully infiltrate the chabazite, put it into a magnetic stirrer, and control The rotating speed is 300r / min, vigorously stirred on a magnetic stirrer for 24 hours (at room temperature), and then left to stand to obtain the modified chabazite.

[0030] (2) After taking out the modified chabazite, wash it with demineralized water, and dry the modified chabazite in an oven at 90°C for 12 hours.

[0031] (3) Taking out the drie...

Embodiment 2

[0035] A method for preparing an adsorbent for removing mercury from coal-fired flue gas of the present invention is basically the same as that in Example 1, the only difference being that the mass concentration of the copper chloride solution is 1 wt%.

Embodiment 3

[0037] A method for preparing an adsorbent for removing mercury from coal-fired flue gas of the present invention is basically the same as that in Example 1, the only difference being that the mass concentration of the copper chloride solution is 10 wt%.

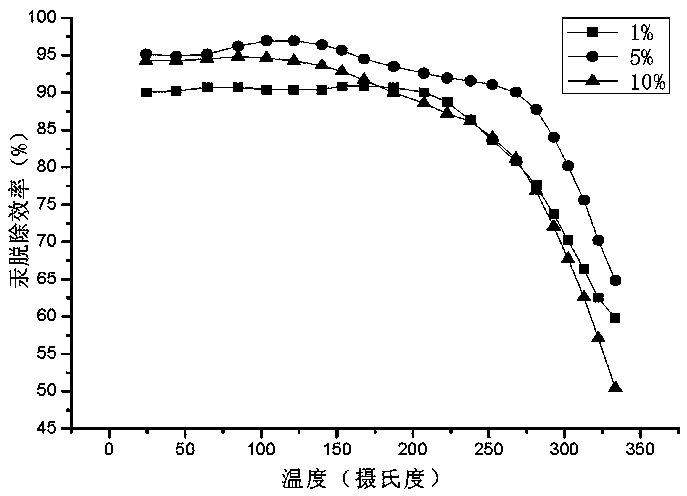

[0038] The coal-fired flue gas mercury-removing adsorbent prepared in the present invention can be applied to the treatment of mercury pollutants in coal-fired boiler flue gas. like figure 1 Shown is the variation curve of the mercury removal efficiency of the adsorbents prepared under different mass concentrations of copper chloride solutions in Examples 1 to 3 as a function of temperature. Wide temperature range, strong adsorption capacity, high adsorption efficiency, and the modification effect of copper chloride solution with a mass concentration of 5% is the best. When the temperature is 25°C, the mercury removal efficiency can reach about 95%. When the temperature reaches At 350°C, the mercury removal efficiency can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com