Method for recycling organic matter through organic waste gas adsorption, steam desorption and fractional condensation

A technology of organic waste gas and graded condensation, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as pollution, high energy consumption, and high cost of condensate separation, and achieve high recovery purity, no secondary pollution, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

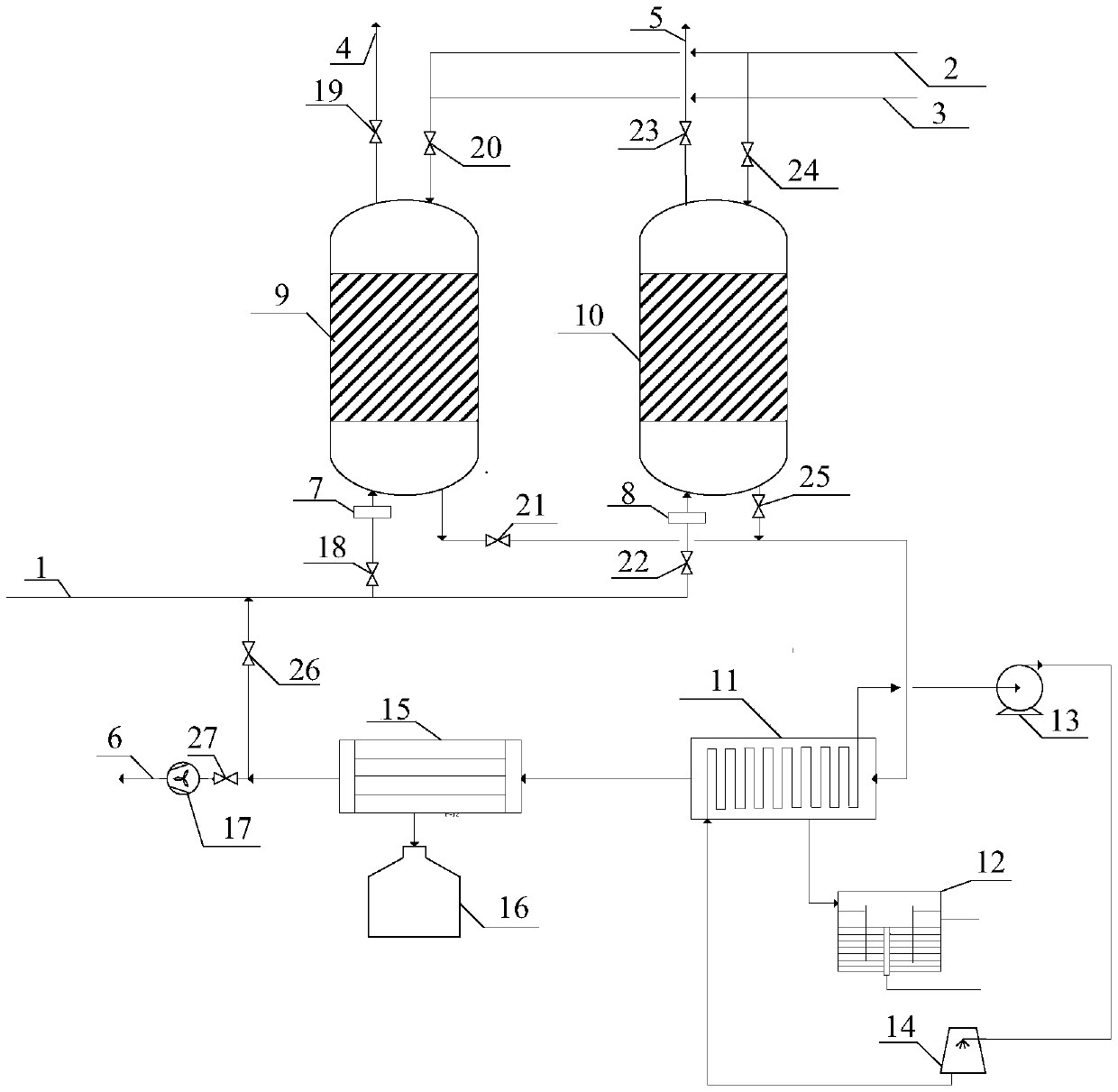

[0035] This embodiment provides an organic waste gas adsorption-steam desorption-staged condensation recovery organic matter device with two adsorbers. The structural diagram is shown in figure 1 . The device includes: 1—exhaust gas inlet; 2—steam inlet; 3—hot air inlet; 4,5—purified gas outlet; 6—cooling air outlet; 7,8—filter cotton; 9,10—adsorber; 11—primary Condenser; 12—oil-water separation device; 13—circulating water pump; 14—circulating water cooling tower; 15—secondary condenser; 16—condensate storage tank; 17—fan; 18—27 are valves.

[0036] The adsorber 9 and the adsorber 10 are filled with honeycomb activated carbon adsorbent.

[0037] The primary condenser 11 is cooled by circulating water; the secondary condenser 15 is refrigerated by vapor compression.

[0038] The filter cotton 7 and the filter cotton 8 can be replaced when the corresponding absorber is in a static state.

[0039] The device is applied to the treatment of exhaust gas in the painting workshop ...

Embodiment 2

[0048] This embodiment provides an organic waste gas adsorption-steam desorption-staged condensation recovery organic matter device with two adsorbers. The structural diagram is shown in figure 1 . The device includes: 1—exhaust gas inlet; 2—steam inlet; 3—hot air inlet; 4,5—purified gas outlet; 6—cooling air outlet; 7,8—filter cotton; 9,10—adsorber; 11—primary Condenser; 12—oil-water separation device; 13—circulating water pump; 14—circulating water cooling tower; 15—secondary condenser; 16—condensate storage tank; 17—fan; 18—26 are valves.

[0049] The adsorber 9 and the adsorber 10 are filled with activated carbon fiber adsorbent.

[0050] The primary condenser 11 adopts circulating water cooling; the secondary condenser 15 adopts absorption refrigeration.

[0051] The filter cotton 7 and the filter cotton 8 can be replaced when the corresponding absorber is in a static state.

[0052] The device is applied to the treatment of dry process waste gas in synthetic leather e...

Embodiment 3

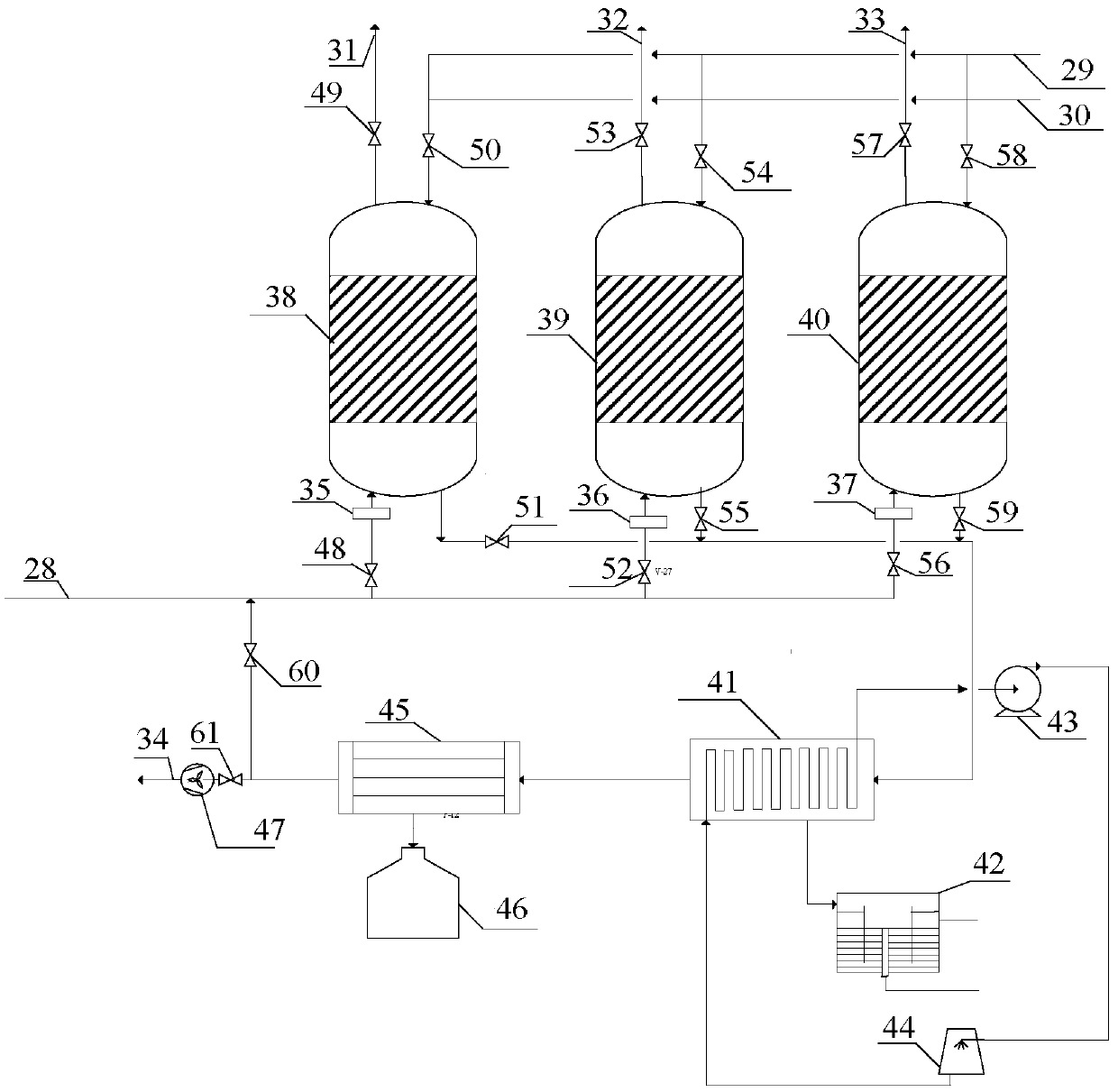

[0061] This embodiment provides an organic waste gas adsorption-steam desorption-staged condensation recovery organic matter device with three adsorbers, the structural diagram is shown in figure 2 . The device includes: 28—exhaust gas inlet; 29—steam inlet; 30—hot air inlet; 31, 32, 33—purified gas outlet; 34—cooling air outlet; 35, 36, 37—filter cotton; 38, 39, 40— Adsorber; 41—primary condenser; 42—oil-water separation device; 43—circulating water pump; 44—circulating water cooling tower; 45—secondary condenser; 46—condensate storage tank; 47—fan; 48—61 is valve .

[0062] The adsorbers 38, 39, 40 are filled with a certain amount of zeolite molecular sieves.

[0063] The primary condenser 41 adopts circulating water cooling; the secondary condenser 45 adopts a semiconductor refrigeration system.

[0064] The filter cottons 35, 36, 37 can be replaced when the corresponding absorbers are in a static state.

[0065] The device is applied to the treatment of exhaust gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com