Cast-in-situ bored pile slurry deposition filtering apparatus and construction method

A technology of bored cast-in-place piles, filter devices, applied in the direction of filter loops, filter separation, separation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The length of a single pile in a pile foundation project is 80m, the pile diameter is 700mm, and the mud output of a single pile is about 150m 3 , the number of construction piles is 10 per day, and the mud is transported abroad, and the treatment cost is 90 yuan / m 3 . In order to reduce the construction cost, the bored pile mud sedimentation filter device is used to reduce the amount of mud transported outside and save construction water.

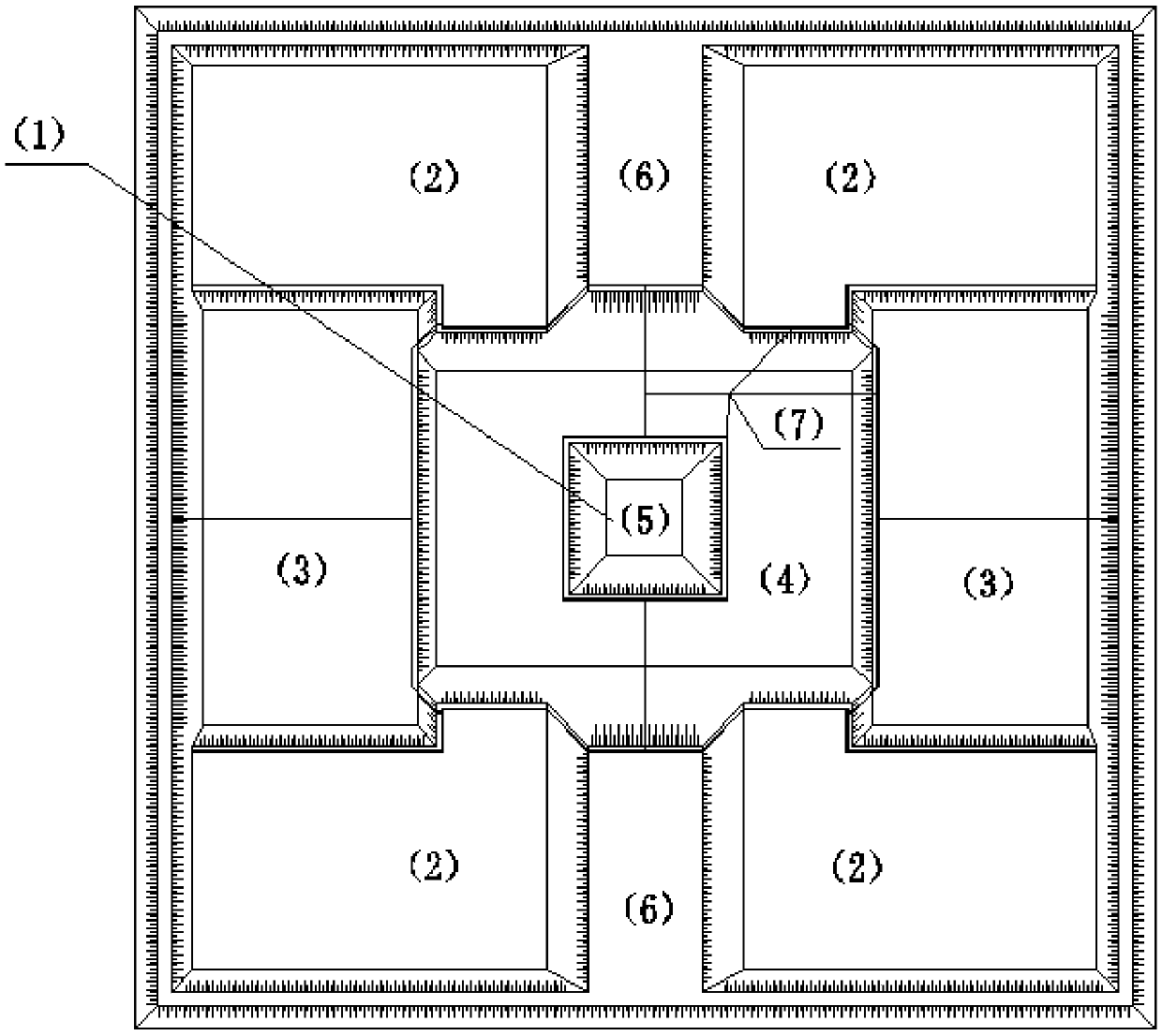

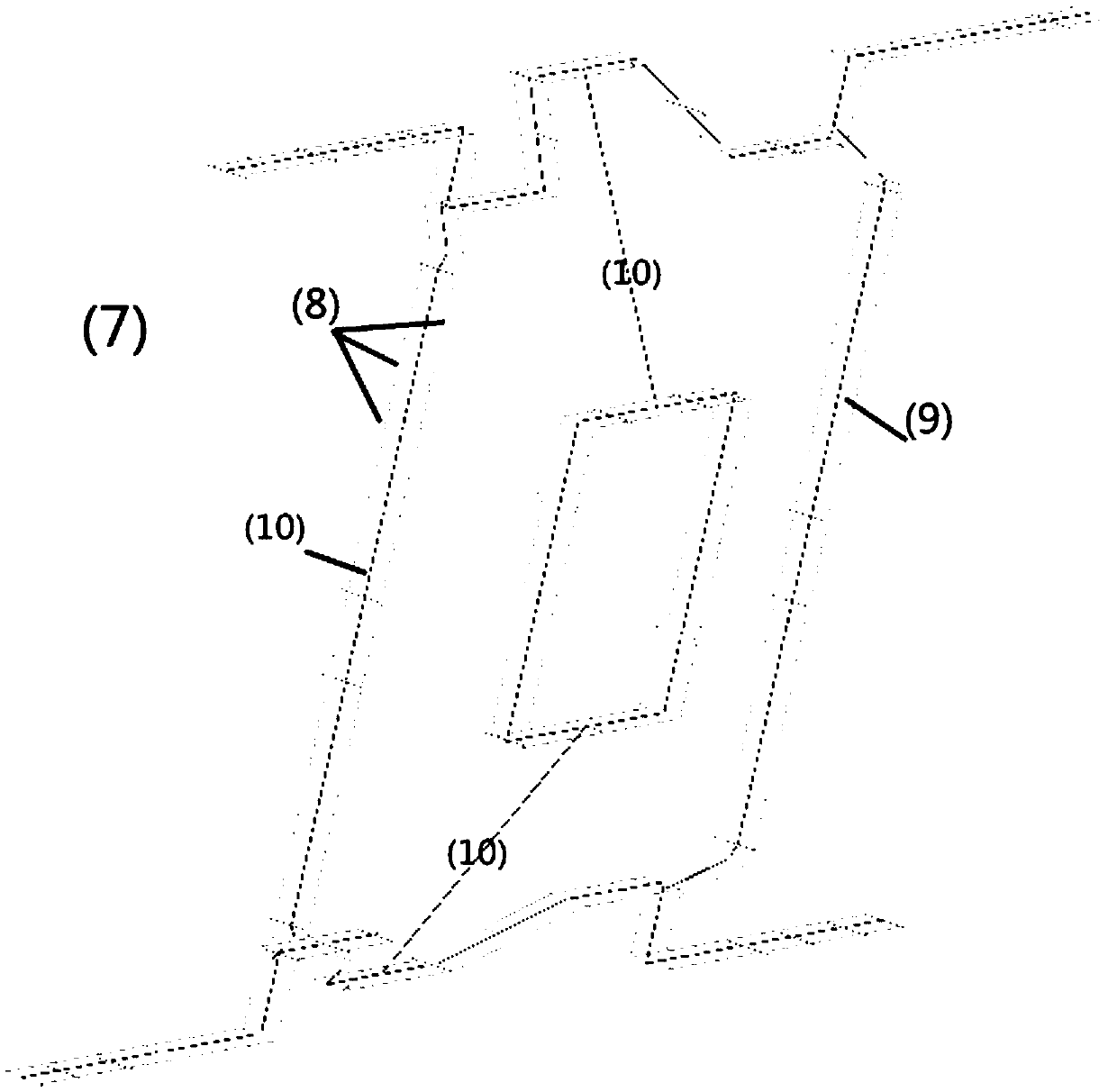

[0028] Such as figure 1 and 2 As shown, a bored pile mud sedimentation filter device includes a four-stage hydraulic height difference sedimentation system 1 and a mud sand filtration system 7, and the four-stage hydraulic height difference sedimentation system 1 is sequentially divided into four stages from the inside to the outside. The first-level clear water pool 5, the third-level purification pool 4, the second-level Sinotrans tank 3, the dredging platform 6 and the first-level dredging tank 2, and the first-level dredging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com