Automatic pineapple processing device

An automatic processing and pineapple technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of manpower not meeting production requirements and low productivity, and achieve easy operation, fast collection, and reduced labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

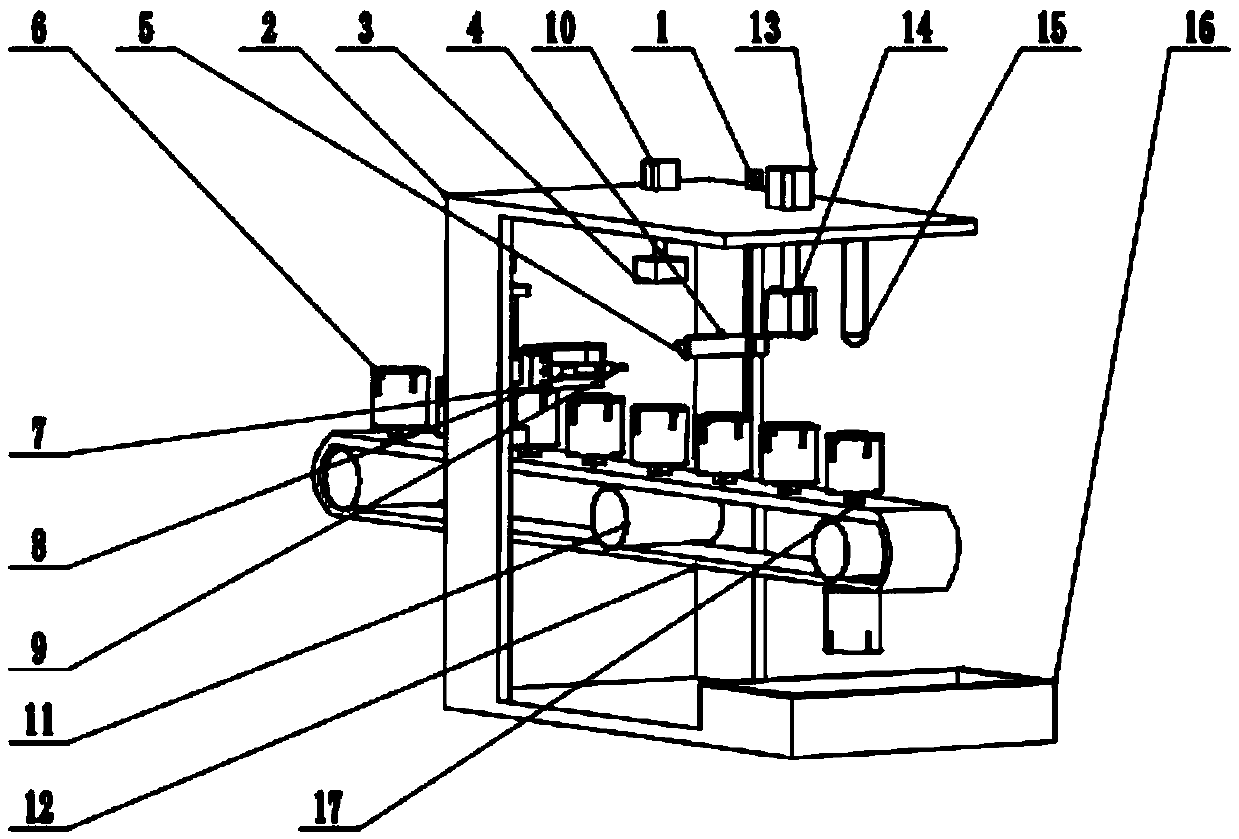

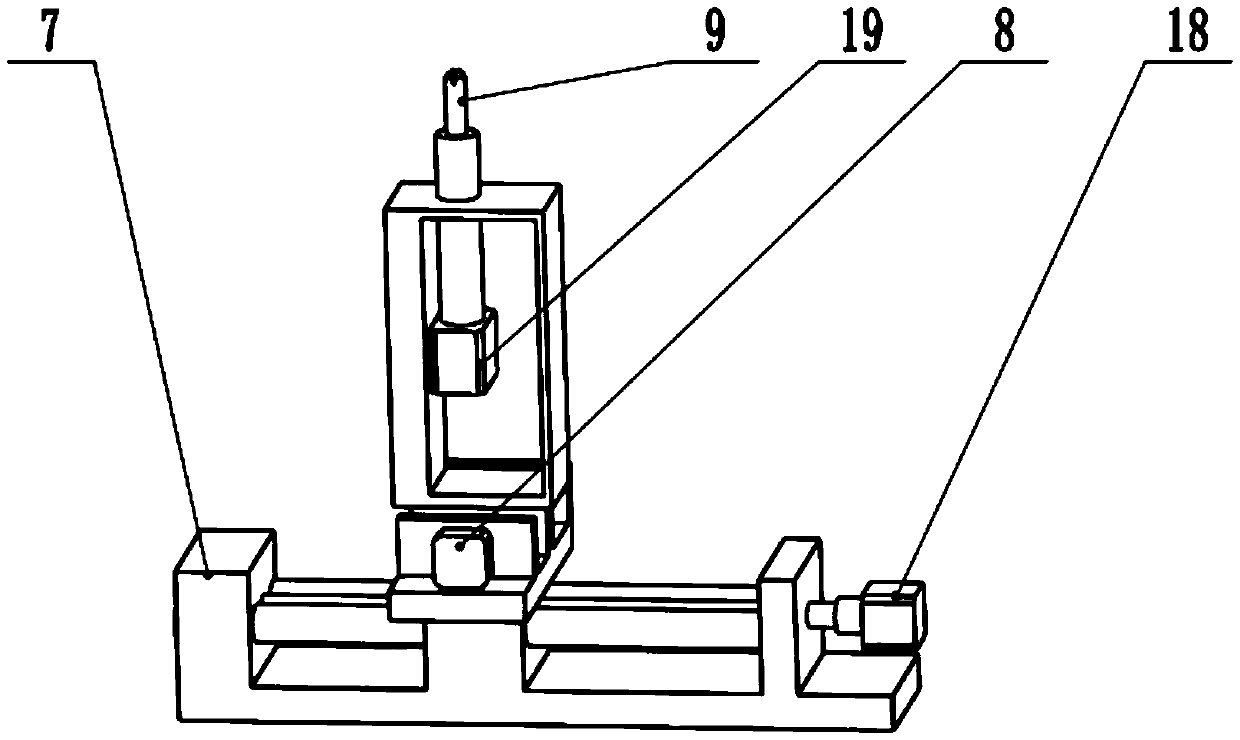

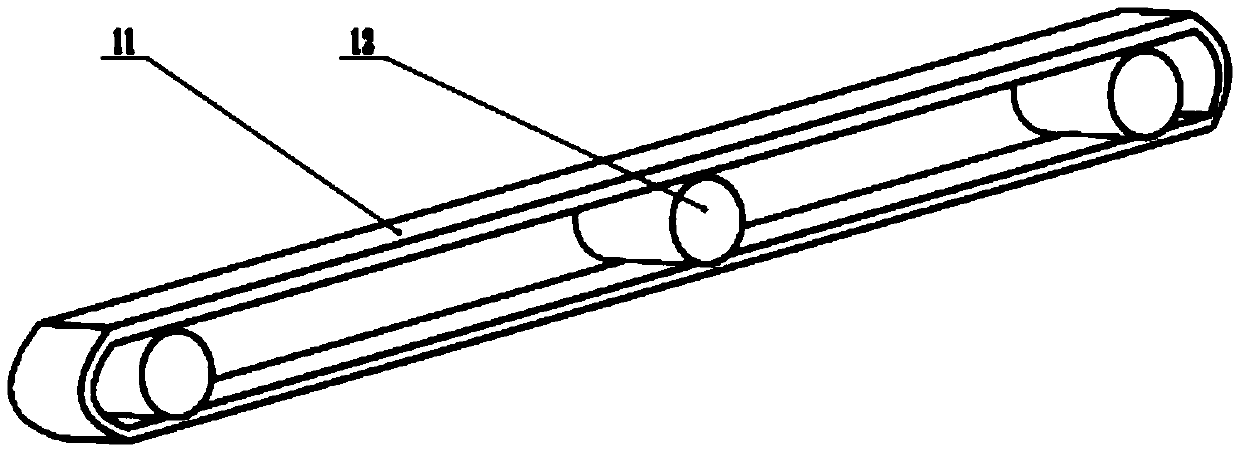

[0020] Please read attached Figure 1-6 , the present invention provides a technical solution: an automatic pineapple processing device, which relates to the field of food automation, has functions such as simplicity, convenience, energy saving, and practicality. , Upper tightening cover 3, Camera 4, Outer circular knife 5, Lower rotating base 6, XY moving table 7, X-direction tool control stepper motor 8, Drilling special tool 9, Control upper tightening cover screw stepper motor 10 , runner 11, conveyor belt 12, control dicing tool screw mandrel stepping motor 13, dicing tool 14, water spray device 15, storage box 16, base rotating motor 17, Y direction tool control stepping motor 18, motor 19, It is characterized in that: a stepping motor 1 for controlling the cutting outer circle tool screw rod is installed on the top of the frame 2, a stepping motor 10 for controlling the tightening cover screw rod, a stepping motor 13 for controlling the screw rod for cutting the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com