Recycling method for waste power lithium ion batteries

A technology of lithium ion battery and lithium iron phosphate battery is applied in the field of lithium ion battery to ensure the service life and improve the effect of consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

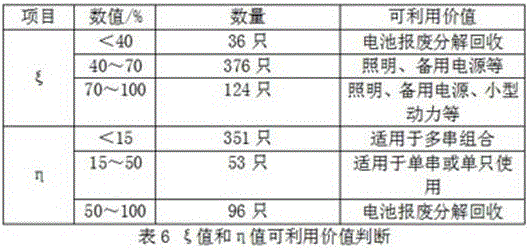

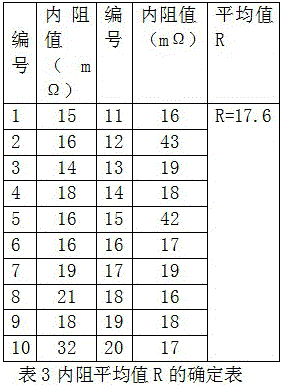

[0040] Taking the recycling method of waste power lithium-ion batteries in the lithium iron phosphate system as an example, and taking the 48V120Ah battery pack as an example, the waste power lithium-ion batteries are collected for information collection, performance testing, and availability judgment. Specific steps are as follows.

[0041] The first step: information collection, check the nameplate, label and other information on the battery pack, collect the positive electrode material system, nominal voltage, and nominal capacity information of the battery pack or module, and make records, among which the nominal capacity is marked for C0.

[0042]

[0043] The second step: performance testing, disassemble all the battery packs into battery cells for testing.

[0044] A: Voltage detection, the detection results are shown in Table 2.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com