Novel flexibly-packaged lithium ion battery and preparation method therefor

A lithium-ion battery and soft pack technology, which is used in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc. The effect of improving the service life and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

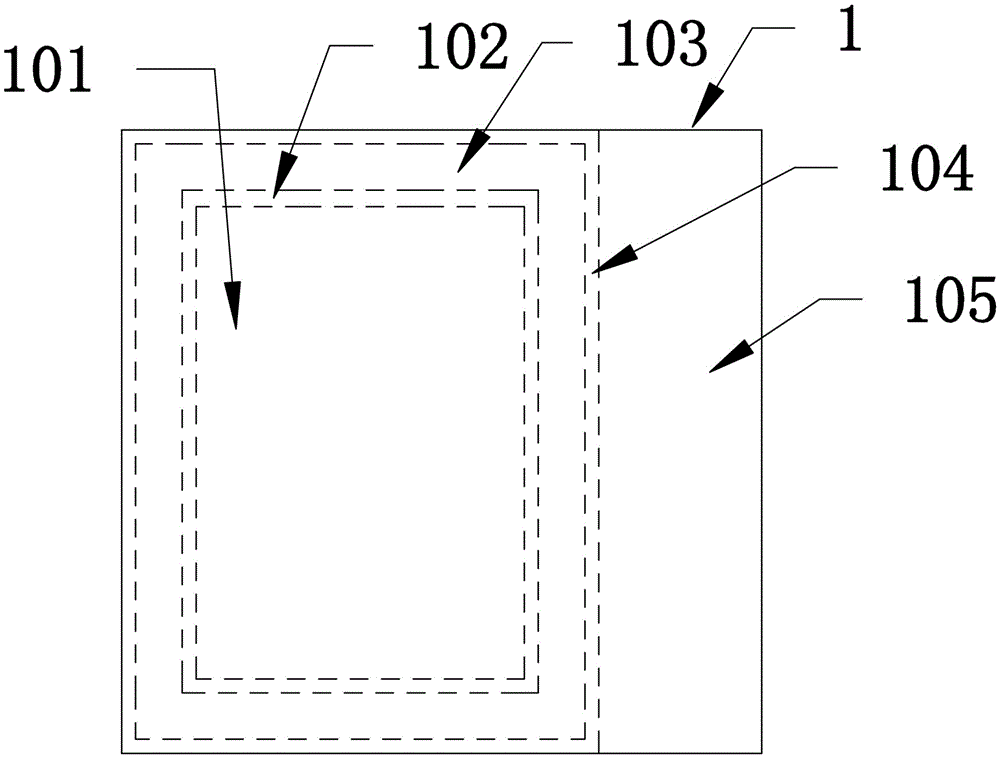

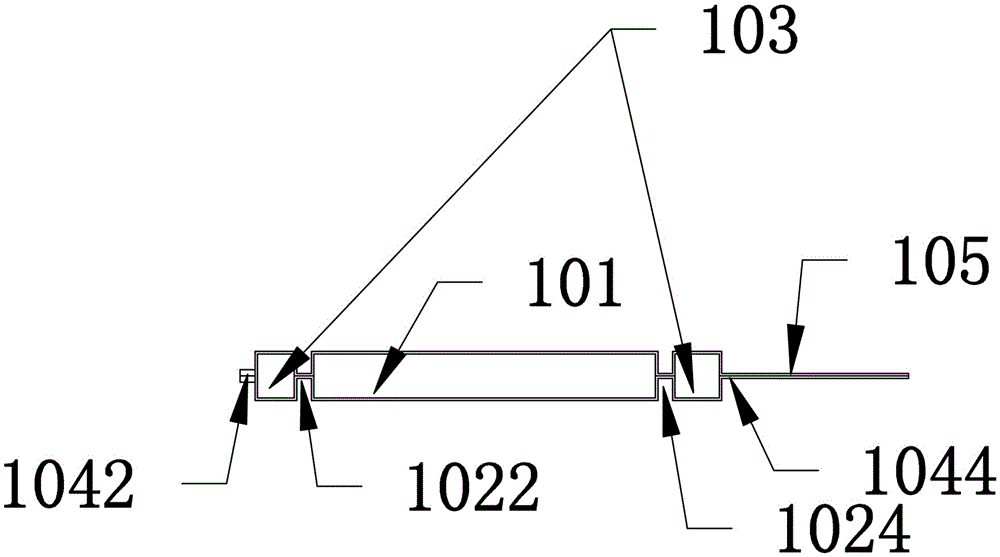

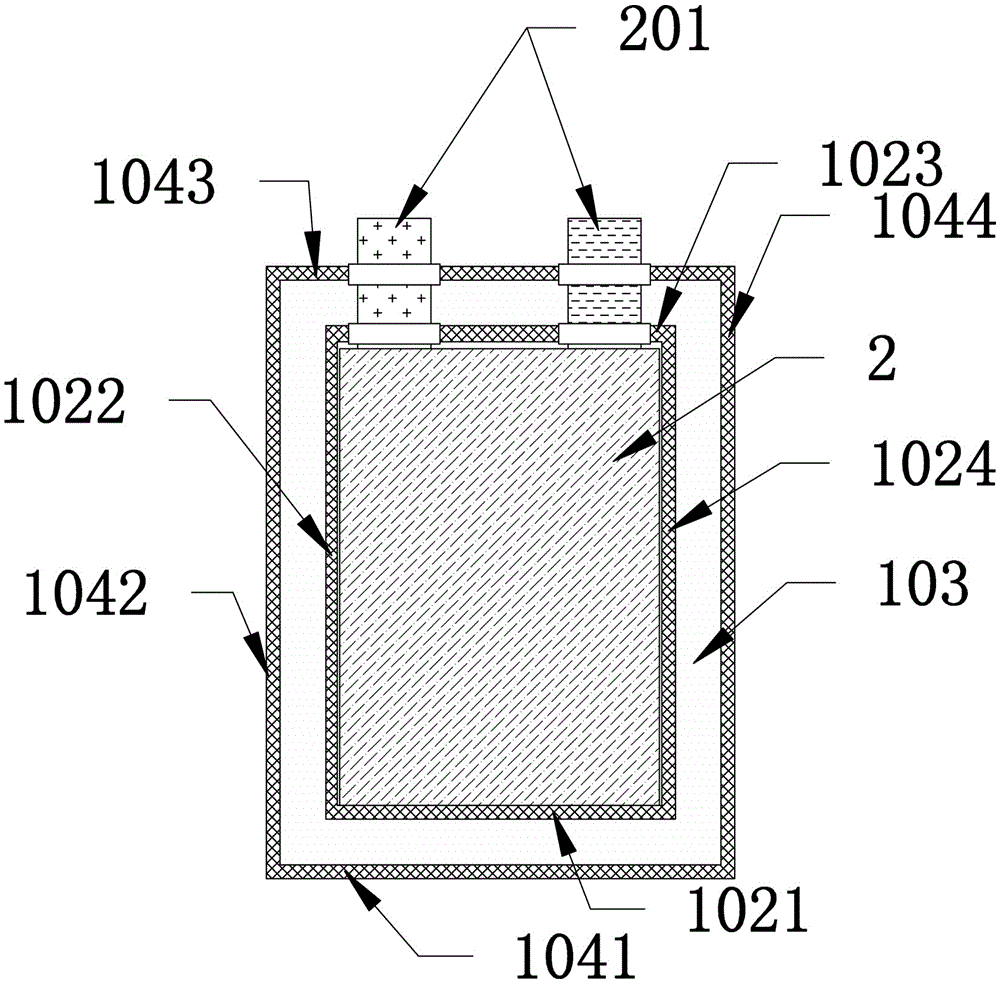

[0028] A new type of aluminum-plastic film for soft-packed lithium-ion batteries such as figure 1 and figure 2 shown. The aluminum-plastic film is formed by adding a circle of pits around the periphery on the basis of traditional aluminum-plastic film forming, that is, the outer edge banding 104 . The cross-sectional view of the new flexible packaging lithium-ion battery is as follows image 3 As shown, the glued lug 201 on the battery cell 2 is a structure of two layers of glue distributed up and down.

[0029] Firstly, the new soft-packed lithium-ion battery cell 2 is packaged with inner bottom sealing edge 1021, inner side sealing edge 1022 and inner top sealing edge 1023. When top sealing, two layers of aluminum-plastic film are sandwiched between the first glue of the two glues. Then carry out conventional battery baking, liquid injection, chemical formation and other processes. After formation, the soft-packed lithium-ion battery is sealed twice. When sealing, first...

Embodiment 2

[0032] A new type of aluminum-plastic film for soft-packed lithium-ion batteries such as figure 1 and figure 2 shown. The aluminum-plastic film is formed by adding a circle of pits around the periphery on the basis of traditional aluminum-plastic film forming, that is, the outer edge banding 104 . The cross-sectional view of the new flexible packaging lithium-ion battery is as follows Figure 4 As shown, the glued lug 201 on the internal cell 2 of the new soft-pack lithium-ion battery is a wide glue structure.

[0033] Firstly, the battery cell 2 of the new soft-packed lithium ion is packaged with inner bottom sealing edge 1021, inner side sealing edge 1022 and inner top sealing edge 1023, and one end of the wide glue is sandwiched between two layers of aluminum-plastic film during top sealing. Then carry out conventional battery baking, liquid injection, chemical formation and other processes. After formation, the soft-packed lithium-ion battery is sealed twice. When sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com