Preparation method for modified diaphragm for lithium-sulfur battery, modified diaphragm and lithium-sulfur battery adopting modified diaphragm

A lithium-sulfur battery and separator technology, applied in the field of lithium-sulfur batteries, can solve the problems of difficulty in further improving the utilization rate of sulfur, difficulty in solving the shuttle effect of polysulfides, high price, etc., so as to improve the capacity and cycle stability, and suppress the shuttle effect. , the effect of reducing battery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a modified diaphragm for a lithium-sulfur battery of the present invention, a modified diaphragm and an embodiment of a lithium-sulfur battery having the modified diaphragm:

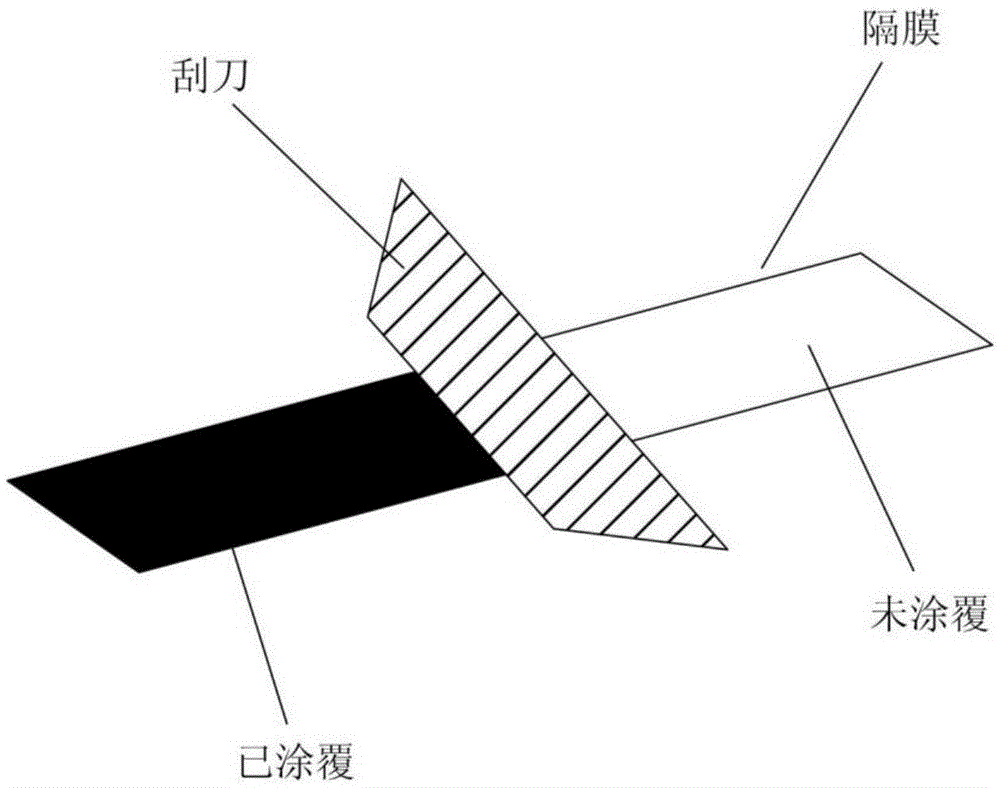

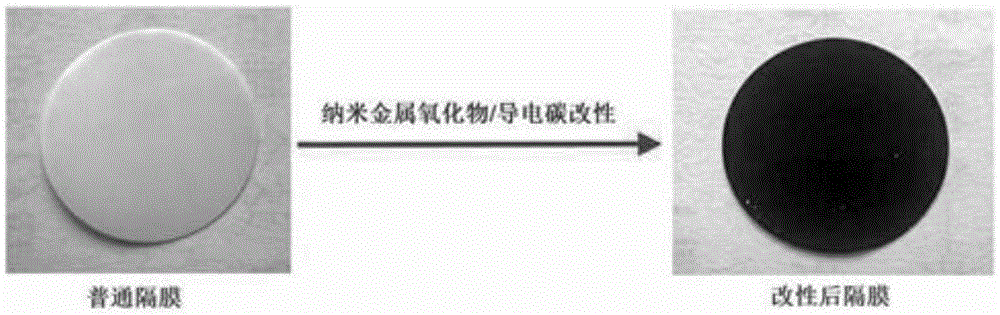

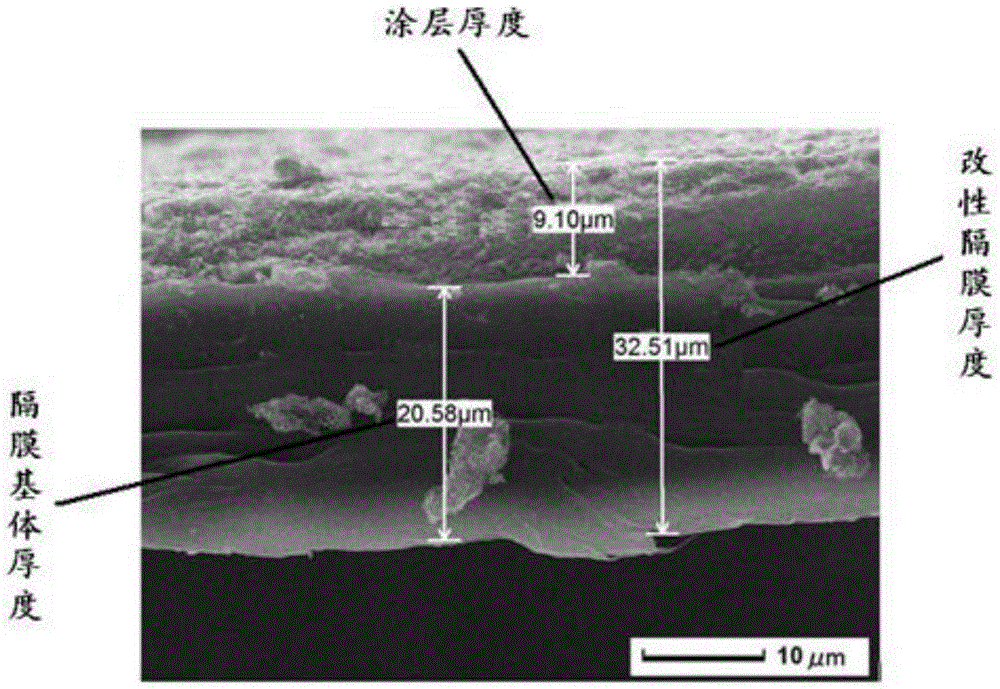

[0037] Modified diaphragm preparation: the prepared Mg 0.6 Ni 0.4 O nanoparticles and Ketjen Black (EC600JD) were mixed in a mass ratio of 1.5:1, and ball milled for 12 hours to obtain a uniformly mixed coating material; : 1 uniformly mixed, and dispersed in the N-methylpyrrolidone solvent, mechanically stirred for 12 hours to obtain a uniformly dispersed coating material; the uniformly dispersed slurry was coated on the polypropylene diaphragm surface (coated by a scraper coating method) operate as figure 1 shown), put the coated diaphragm into a vacuum drying oven, and dry it at 50°C for 6 hours to obtain a modified diaphragm (the appearance of the modified diaphragm is as follows figure 2 shown).

[0038] Battery assembly: the carbon / sulfur (mass ratio of carbon / sul...

Embodiment 2

[0043] A preparation method of a modified diaphragm for a lithium-sulfur battery of the present invention, a modified diaphragm and an embodiment of a lithium-sulfur battery having the modified diaphragm:

[0044] Modified diaphragm preparation: the prepared Mg 0.8 Cu 0.2 O nanoparticles and conductive carbon black (BP2000) were mixed in a mass ratio of 2:1, and ball milled for 12 hours to obtain a uniformly mixed coating material; 3:1 uniform mixing, and dispersed in N-methylpyrrolidone solvent, ultrasonic dispersion for 12 hours to obtain a uniformly dispersed coating material; use a doctor blade to coat the uniformly dispersed slurry on the surface of the polyacrylonitrile diaphragm, The coated separator was put into a vacuum drying oven, and dried at 50° C. for 12 hours to obtain a modified separator.

[0045] Battery assembly: the carbon / sulfur (mass ratio of carbon / sulfur is 1:4, the sulfur content accounts for 80% of the mass of the electrode sheet) composite material...

Embodiment 3

[0049] A preparation method of a modified diaphragm for a lithium-sulfur battery of the present invention, a modified diaphragm and an embodiment of a lithium-sulfur battery having the modified diaphragm:

[0050] Preparation of modified separator: the prepared TiO 2 Mix the nanoparticles and acetylene black at a mass ratio of 5:1, and ball mill for 12 hours to obtain a uniformly mixed coating material, then uniformly mix the uniformly mixed coating material with polyvinyl alcohol at a mass ratio of 4:1, and disperse into the acetone solvent, mechanically stirred for 12 hours to obtain a uniformly dispersed coating material; use a scraper to coat the uniformly dispersed slurry on the surface of the PTFE diaphragm, and put the coated diaphragm into a vacuum drying oven , dried at 50°C for 8 hours to prepare a modified separator.

[0051] Battery assembly: the carbon / sulfur (mass ratio of carbon / sulfur is 1:4, the sulfur content accounts for 80% of the mass of the electrode she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com