Railway vehicle axle phased array ultrasonic flaw detection platform

An ultrasonic flaw detection and rail vehicle technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of large number, prone to missed inspections, cumbersome processes, etc., and achieves a high degree of automation, coverage, and high detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below through the accompanying drawings and embodiments.

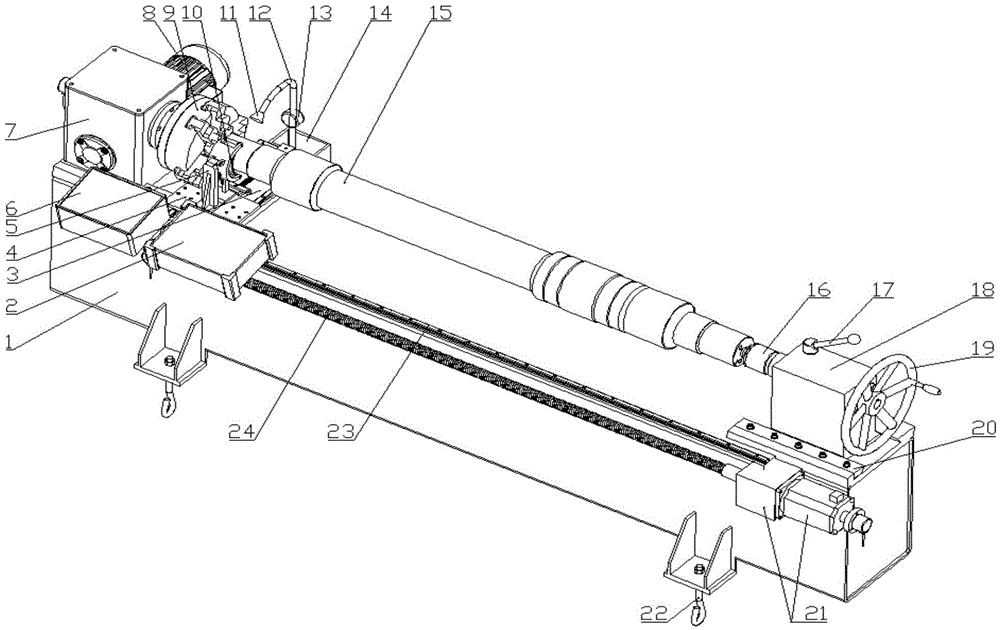

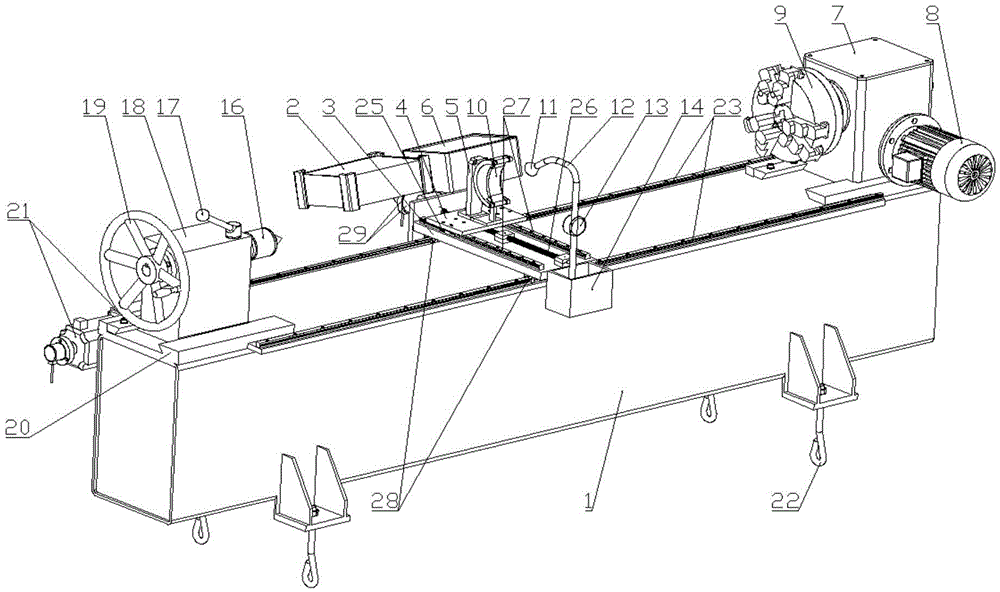

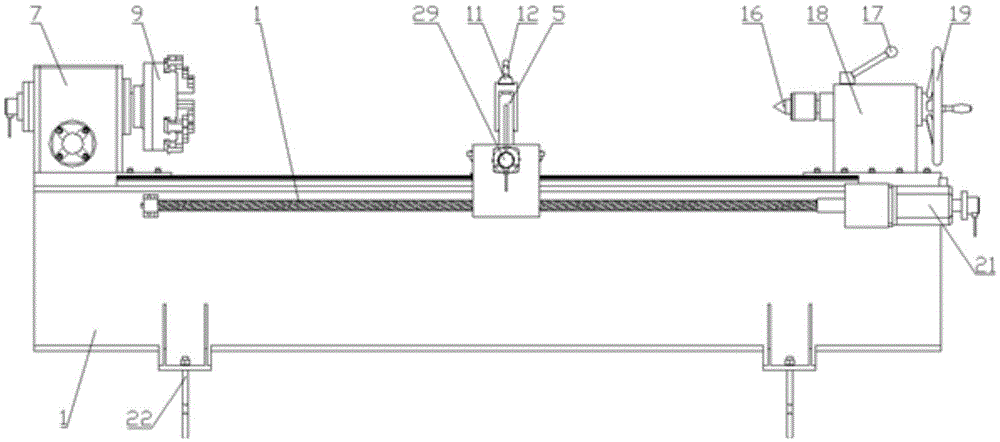

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 7 As shown, the present invention discloses a rail vehicle axle phased array ultrasonic flaw detection platform, including a bed 1, an axle clamping device, a spindle drive transmission mechanism, a detection mechanism, a coupling agent spraying device, a control mechanism, and a phased array flaw detector 2 and related connectors;

[0035] The bed 1 is used as the basis for the installation and acceptance of the rest of the components. It adopts an angle steel frame, and its main body surface is made of steel plates, and is fixed on the ground with anchor bolts 22;

[0036] Such as Image 6 As shown, the spindle drive transmission mechanism includes a spindle motor 8 fixed on the bed 1 and a spindle worm gear reducer 7 for driving the axle to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com