Corrosion morphology quantitative detection method of outer wall of pipeline

A quantitative detection method, a technology for the outer wall of a pipeline, which is applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve the problems of high detection cost, small measurement range, low measurement accuracy, etc., and achieves strong anti-interference ability and measurement range. The effect of large, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for quantitative detection of corrosion appearance on the outer wall of a pipeline, which includes the following steps:

[0027] Step 1) Collect point clouds on the surface of the corroded pipeline;

[0028] Step 2) reversely restore the collected point cloud to a 3D solid image of the pipeline;

[0029] Step 3) Analyze the three-dimensional solid image of the pipe surface, take the inner wall as the reference plane, and the outer wall as the test object to obtain the actual pipe wall thickness in different areas, and use different colors to represent different actual pipe wall thicknesses to reflect different areas of the outer wall of the pipe The size of the degree of corrosion.

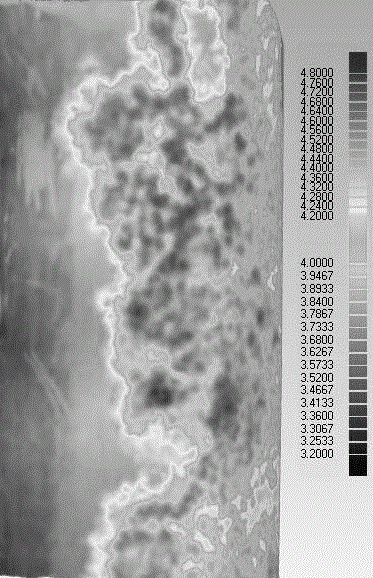

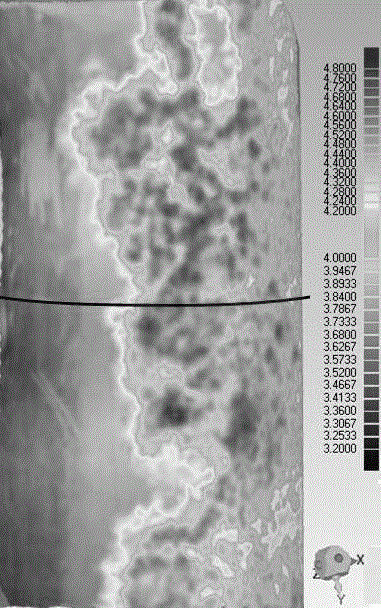

[0030] After the point cloud is collected, the corrosion pipeline is reversely restored, and the following is obtained: figure 1 The three-dimensional topography of corrosion on the pipeline surface is shown, figure 1 The appearance of the outer wall sho...

Embodiment 2

[0032] On the basis of Example 1, the specific process of point cloud acquisition on the surface of the corroded pipeline is as follows:

[0033] (1) Remove the paint and corrosion products on the outer surface of the pipeline, remove the rust on the surface with a copper brush, and clean the surface of the pipeline with alcohol and acetone, so that the matrix on the surface of the pipeline is completely exposed;

[0034] (2) Apply a layer of white imaging agent evenly on the outer surface of the pipe, then paste at least three marking points on the outer surface, and then use the calibration plate to calibrate;

[0035] (3) Start scanning, and project gratings of various frequencies onto the pipeline of the object to be tested through the grating projector, and two CCD cameras receive a corresponding angled image at the same time, and then decode and phase calculate the image;

[0036] (4) Multi-view and multiple omni-directional scans are performed on the surface of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com