a shotgun

A shotgun and gun body technology, which is applied in the field of shotguns, can solve the problems of reducing production efficiency, preventing jumping damage, and preventing jumping loss, and achieves the effects of reducing production costs, preventing loss, and increasing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

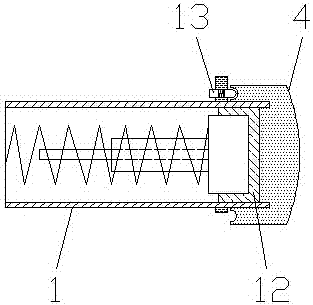

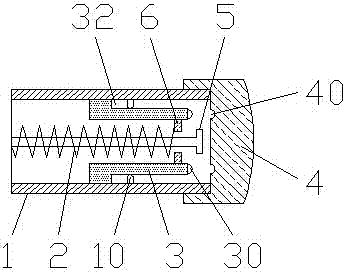

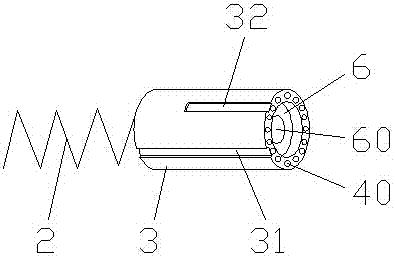

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] As shown in the figure, a shotgun includes a gun body, a bolt locking mechanism located in the gun body, a magazine barrel 1 located below the gun body, and a locking screw located at the front end of the magazine barrel 1. The cap 4 is characterized in that: a limit button 10 is provided on the inner wall of the magazine barrel 1, a guide shaft 3 and a spring 2 are respectively arranged in the magazine barrel 1, and the spring 2 is located on the guide shaft 3 The end of the guide shaft 3 is respectively provided with a through groove 31 and a limit groove 32, and a perforation 60 is provided in the guide shaft 3, and the perforation 60 is used to place the limiter rod 5, the limit groove 32, the through The slot 31 and the stop buckle 10 are symmetrically arranged, and the difference between the through slot 31 and the stop slot 32 is 90 degrees, so that whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com