A polygonal wind power tower and its manufacturing method

A polygonal, polygonal tube technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, installation/supporting the configuration of wind turbines, etc., can solve problems such as large bearing capacity, top steel waste, waste, etc. Material wastage, effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples.

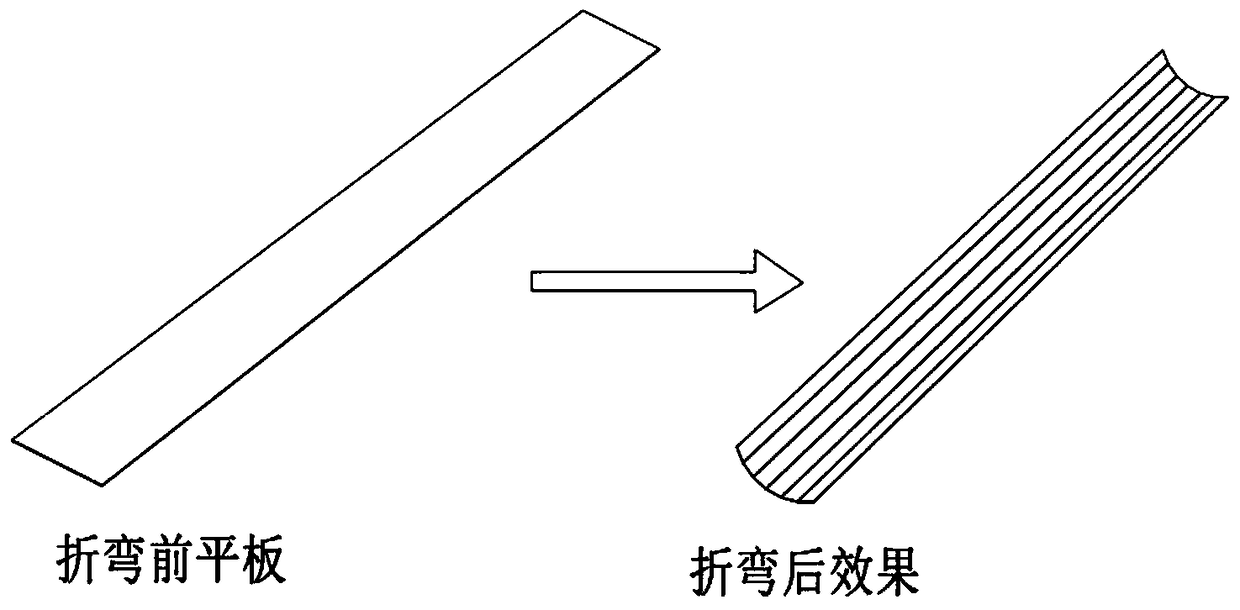

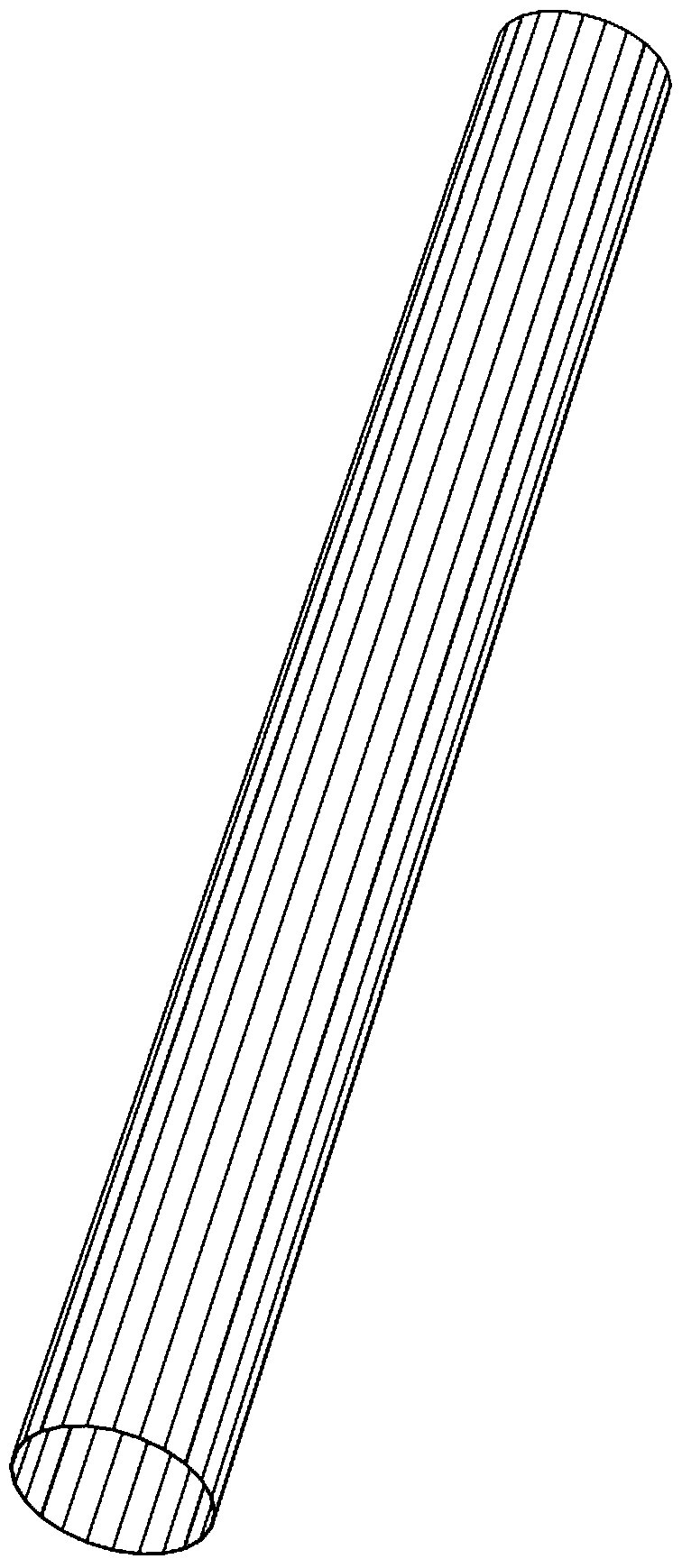

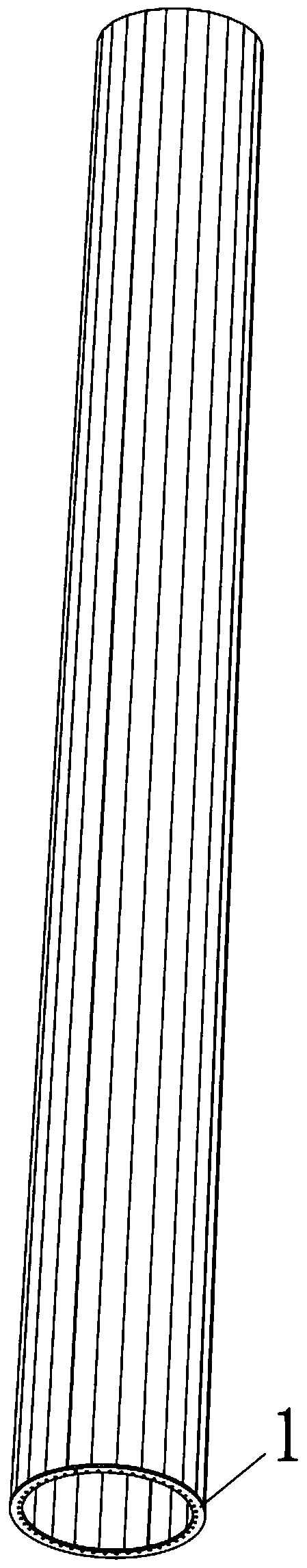

[0034] Such as Figure 1 to Figure 7 As shown, the polygonal wind power tower described in this embodiment includes at least two tower sections, and the horizontal cross-section of each tower section is a polygonal structure. Due to the polygonal structure, the tower does not need a coiling machine Production can be changed to a bending machine; two tower sections are connected by welded flanges 1 (made of ring forgings or welded parts), and bolts 2 are used to connect the flanges 1 of the two tower sections Fixing is carried out, and then the tower sections are connected into a whole, and longitudinal ribs 3 are welded on the flange 1 for reinforcement, and the longitudinal ribs 3 are also welded together with corresponding tower sections. In this way, the horizontal plane of the tower does not have welds or welds are reinforced, thereby avoiding the weak phenomenon. And be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com