Safe environmentally-friendly combined type plastic cement racetrack and manufacturing method thereof

A plastic runway, safety and environmental protection technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of limitation, long construction period, etc., and achieve the effect of good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

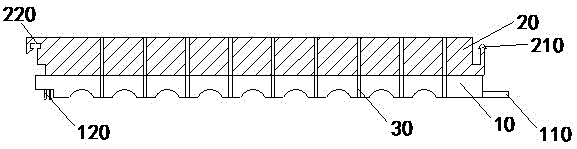

[0026] Such as Figure 1~3 As shown, a safety and environment-friendly combined plastic runway includes a mobile receiving plate 10 at the bottom and a plastic surface layer 20 arranged above the mobile receiving plate. There are interlocking locks between adjacent plastic surface layers 20, and the corresponding There is a locking clip adjacent to the peripheral side of the moving receiving plate.

[0027] The locking clip of the moving receiving plate 10 includes a collar 110 disposed on an adjacent side and an elastic protruding pin 120 correspondingly disposed on the side where the collar is located. A flange is provided on the edge of the elastic protruding pin 120 to securely lock the collar 110 on the outer edge of the elastic protruding pin 120. The elasticity of the material of the elastic protruding pin itself is used to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com