Biodiesel continuous esterification reaction tower

A technology of esterification reaction and biodiesel, which is applied in the direction of biofuel, fatty acid esterification, petroleum industry, etc., to achieve high esterification reaction efficiency, reasonable design, and improve the effect of esterification reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

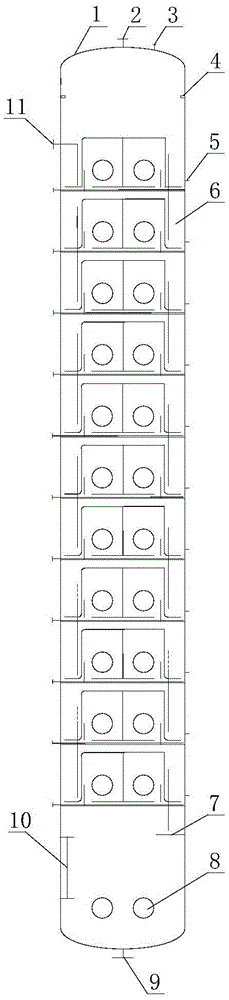

[0020] exist figure 1 Among them, the biodiesel continuous esterification reaction tower of this embodiment consists of a reaction tower shell 1, a methanol outlet pipe 2, a top pressure gauge 3, a demister 4, a temperature monitor 5, a tower section 6, a liquid baffle 7, a tower The bottom heater 8, the oil outlet pipe 9, the liquid level gauge 10, and the feed pipe 11 are connected to form.

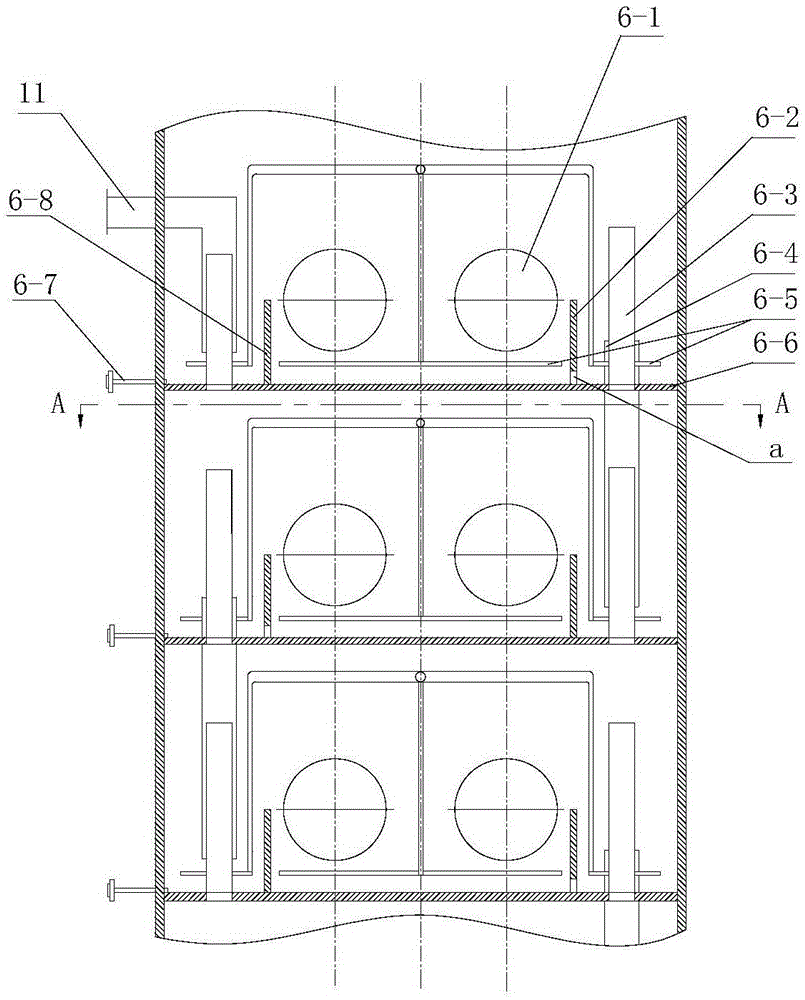

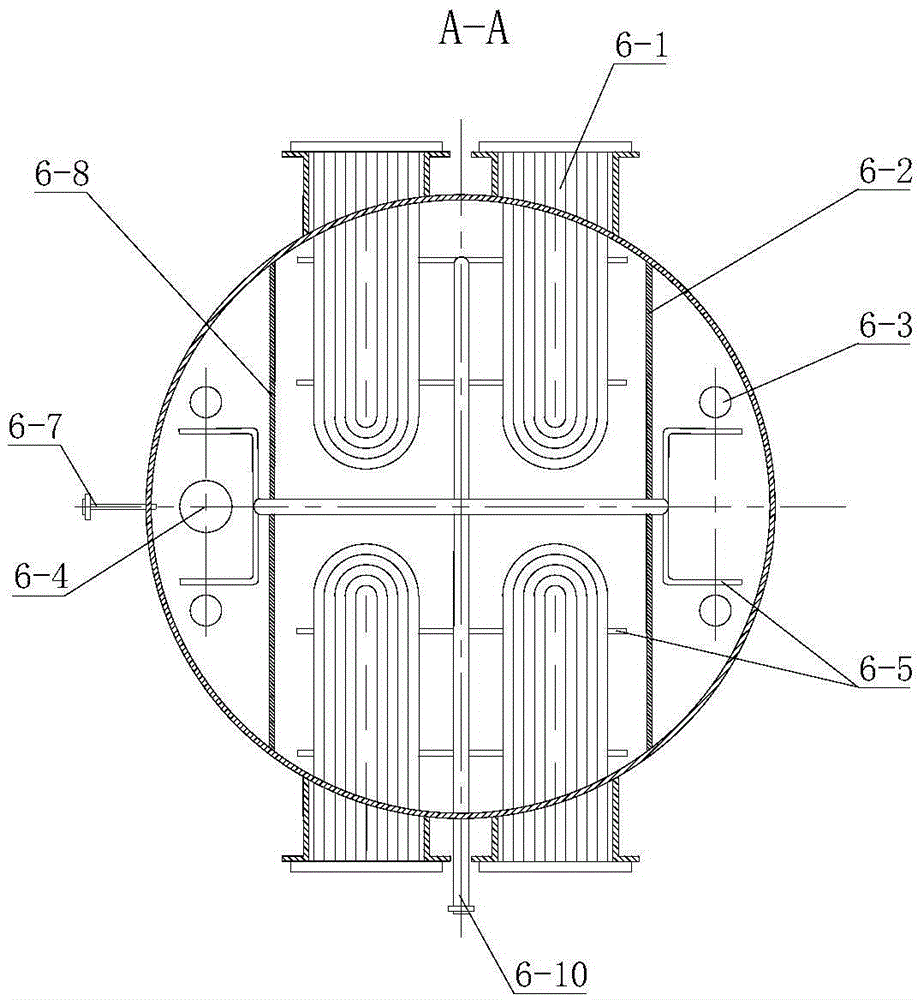

[0021] The geometric shape of the reaction tower shell 1 is a cylinder with a cross-sectional diameter of 2000mm. On the top head of the reaction tower shell 1, a methanol outlet pipe 2 and a top pressure gauge 3, a methanol outlet pipe 2 and a top pressure gauge 3 are installed. It communicates with the inner cavity of the reaction tower, and the demister 4 is installed under the head of the top of the reaction tower shell 1. The middle part of the reaction tower shell 1 is installed with 11 interconnected tower sections 6 from top to bottom, and each tower section 6 A temperature mon...

Embodiment 2

[0026] In the present embodiment, the geometric shape of the reaction tower shell 1 is cylindrical, and the cross-sectional diameter is 1500 mm. The middle part of the reaction tower shell 1 is equipped with 8 interconnected tower sections 6 from top to bottom. An overflow liquid barrier 6-8 and a downstream liquid barrier 6-2 are installed on the section bottom plate 6-6 to divide the tower section chamber into 3 chambers, and the bottom of the downstream liquid barrier 6-2 is processed with slotted holes a. The height of the overflow liquid separator 6-8 is 400mm, the vertical distance between the overflow liquid separator 6-8 and the center line of the tower section bottom plate 6-6 is 500mm, and the height of the downstream liquid separator 6-2 The height is equal to the overflow liquid separator 6-8, the vertical distance between the downstream liquid separator 6-2 and the center line of the tower section bottom plate 6-6 is 400mm, and there are 4 inner diameters distribut...

Embodiment 3

[0028]In the present embodiment, the geometric shape of the reaction tower shell 1 is cylindrical, and the cross-sectional diameter is 3000mm. The middle part of the reaction tower shell 1 is equipped with 15 interconnected tower sections 6 from top to bottom, and the tower section 6 of the tower section 6 An overflow liquid barrier 6-8 and a downstream liquid barrier 6-2 are installed on the section bottom plate 6-6 to divide the tower section chamber into 3 chambers, and the bottom of the downstream liquid barrier 6-2 is processed with slotted holes a. The height of the overflow liquid separator 6-8 is 700mm, the vertical distance between the overflow liquid separator 6-8 and the center line of the tower section bottom plate 6-6 is 900mm, and the height of the downstream liquid separator 6-2 The height is equal to the overflow liquid separator 6-8, the vertical distance between the downstream liquid separator 6-2 and the center line of the tower section bottom plate 6-6 is 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com