Sliding type cutting and fixing device

A fixed device and sliding technology, which is applied in the direction of shearing devices, shearing machine accessories, measuring/indicating equipment, etc., can solve the problems of inconvenient operation, and achieve the effect of convenient pulling operation, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

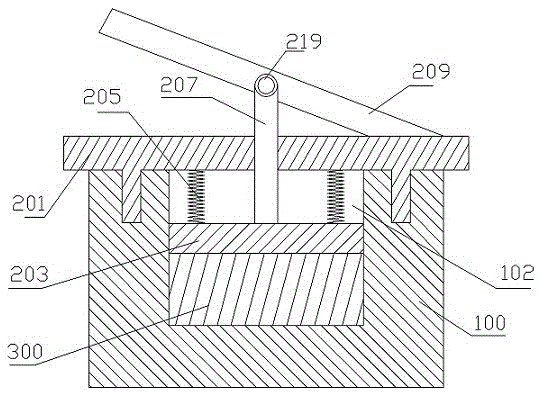

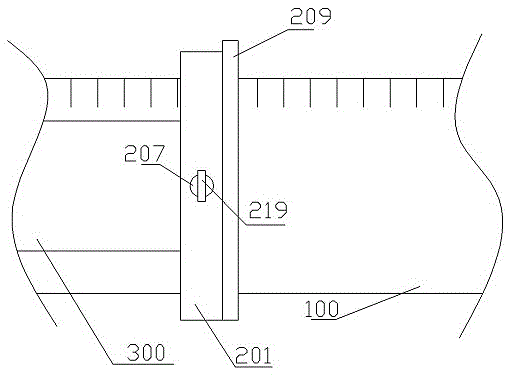

[0015] The reference numerals in the accompanying drawings of the description include: workbench 100 , working groove 102 , slide plate 201 , fixed plate 203 , spring 205 , connecting rod 207 , cutting knife 209 , pull ring 219 , and plate 300 .

[0016] Such as figure 1 and figure 2 The sliding cutting and fixing device shown includes a workbench 100, a cutting knife 209 and a fixing mechanism. The workbench 100 is provided with a chute and a working groove 102, the surface of the chute is provided with a polishing layer, and the workbench 100 is provided with a scale Table, the fixing mechanism includes a slide plate 201 and a fixed plate 203, one side of the slide plate 201 is hinged with the cutting knife 209, the lower end of the slide plate 201 is slidably connected with the chute, the bottom of the slide plate 201 is connected with a spring 205, and the spring 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com