Metal tube drilling machine convenient to dismount

A technology for easy disassembly and metal pipe, applied in metal processing mechanical parts, boring/drilling, metal processing equipment, etc., can solve the problems of rough processing, waste of financial and material resources, expensive purchase, etc., to achieve high processing accuracy and simple structure , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

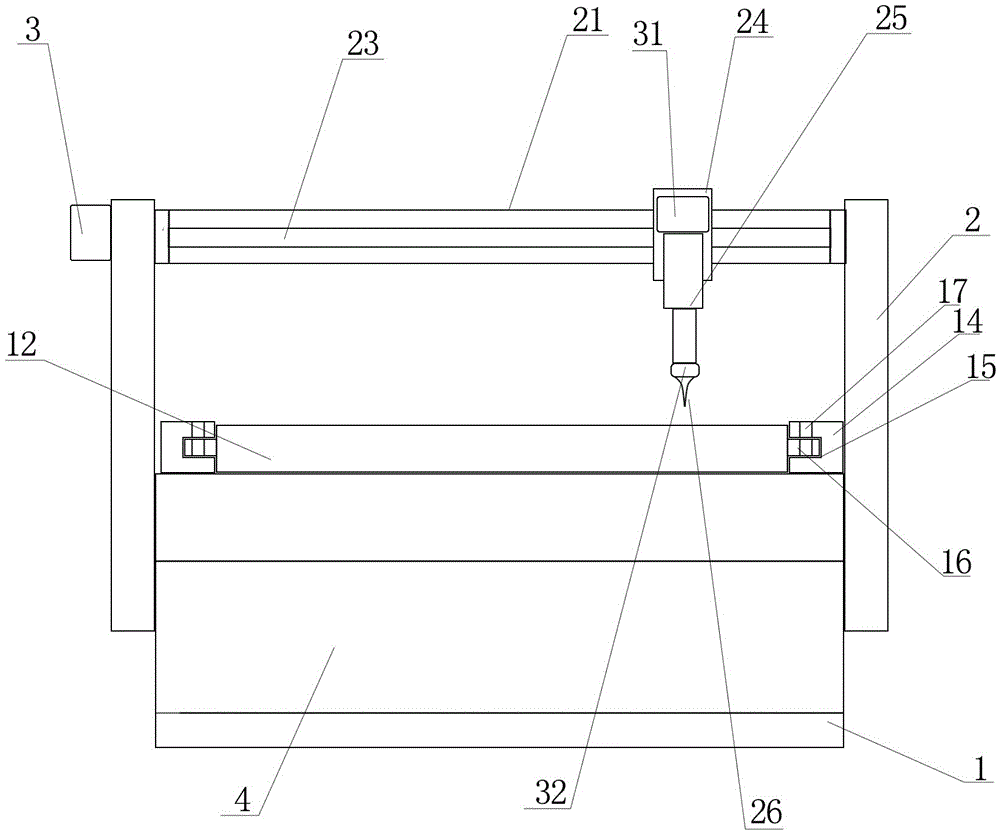

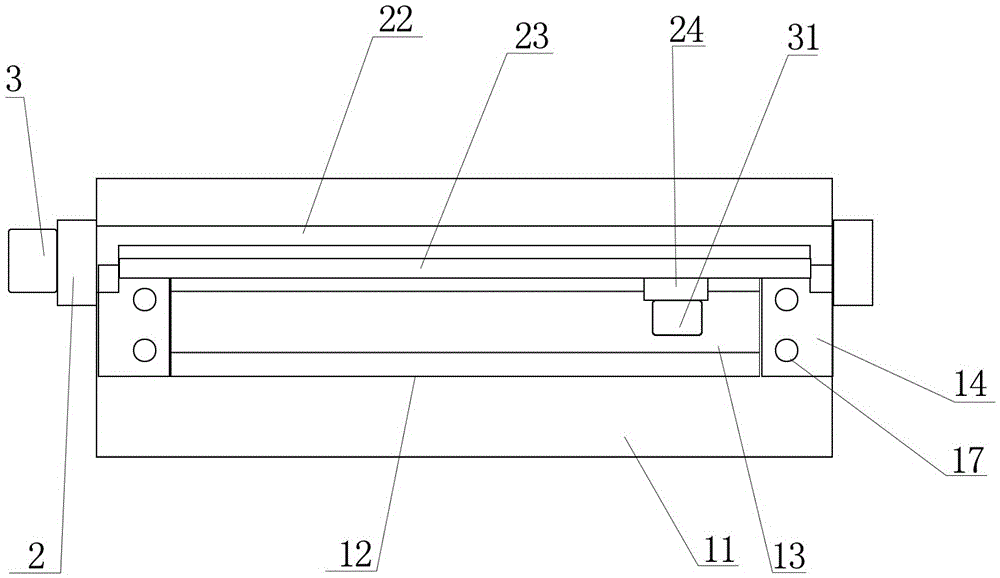

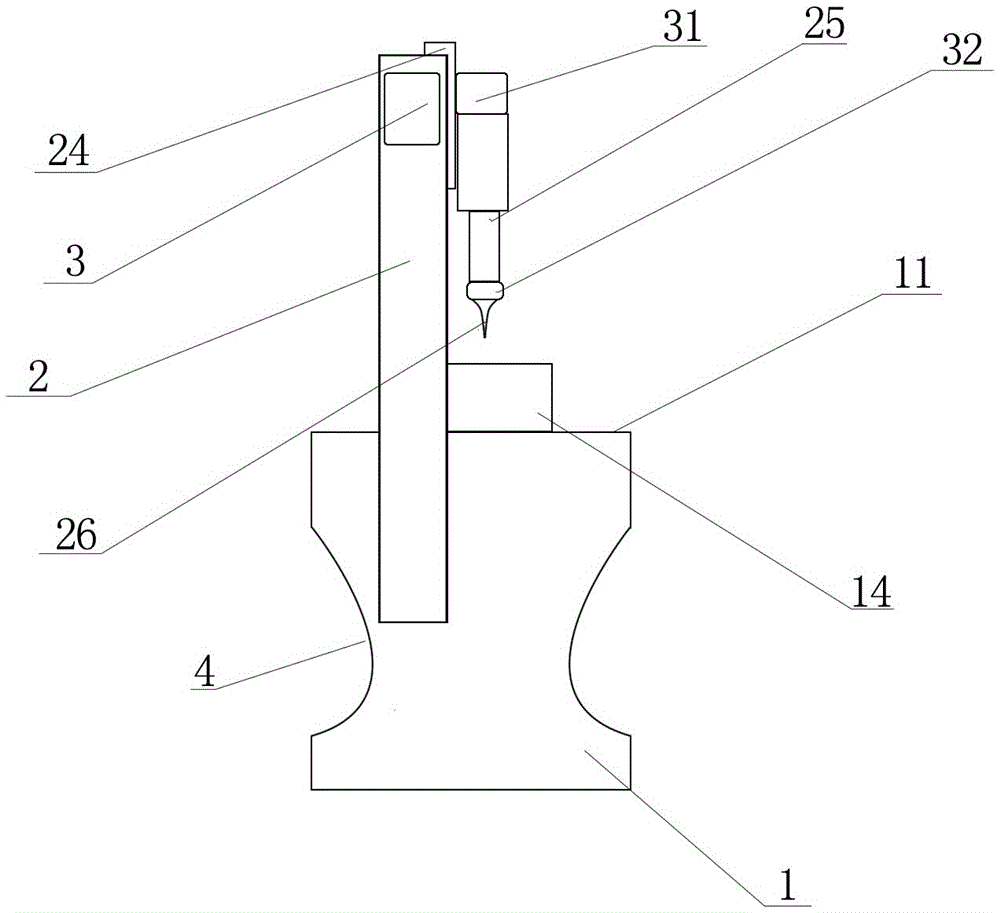

[0015] like Figure 1 to Figure 3 As shown, a metal pipe drilling machine that is easy to disassemble according to the present invention includes a support 1, which is characterized in that: the top of the support 1 is a horizontal plane 11, and two sides of the plane 11 are respectively provided with a mounting seat 14 , the mounting seat 14 is arranged in a rectangular shape, and a through groove 15 is arranged inwardly on the adjacent two sides of the mounting seat 14, and a strip-shaped metal pipe fixing seat 12 is arranged between the two mounting seats 14, and the two sides of the metal pipe fixing seat 12 A fixed piece 16 corresponding to the through groove 15 is provided, a plurality of fixed holes 17 are provided on the fixed piece 16 and the mounting seat 14, and a rectangular concave hole for placing the metal pipe is arranged downward on the top of the metal pipe fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com