Parallel-cutting crusher

A crusher and rack technology, applied in the field of garbage processing equipment, can solve the problems of poor crushing effect and unfavorable recycling, and achieve the effect of meeting the requirements of shearing and crushing, the shape is regular, and the recycling is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

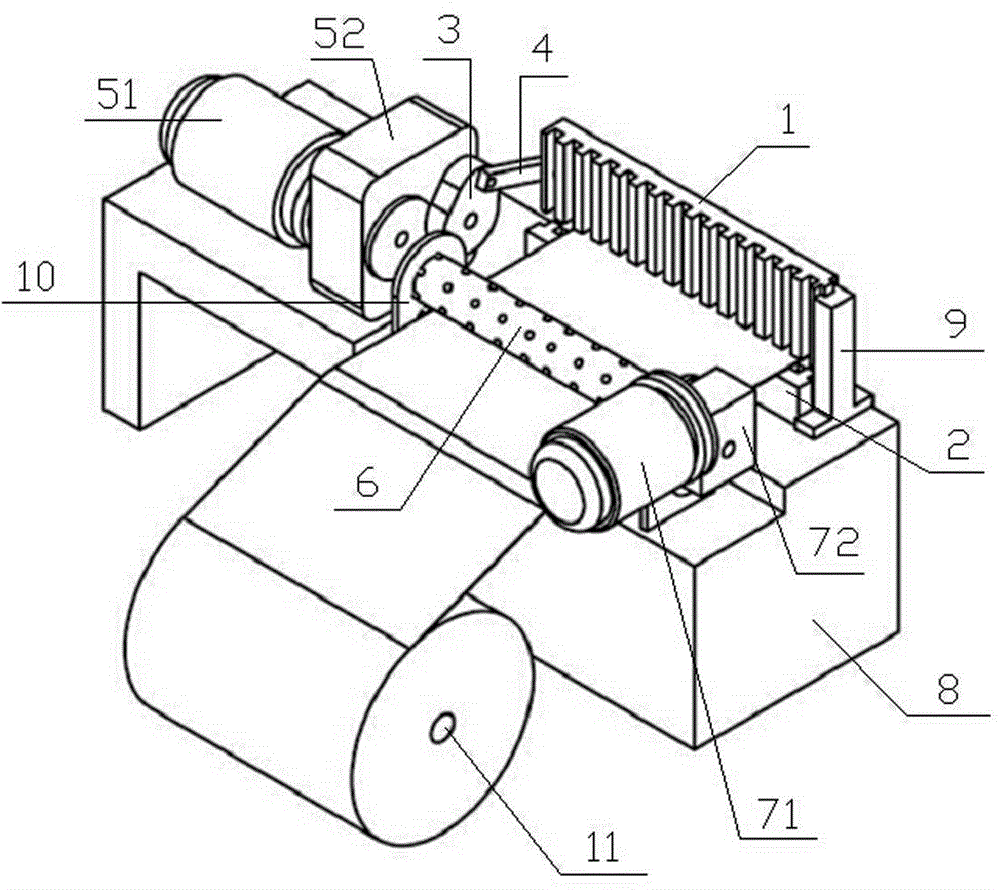

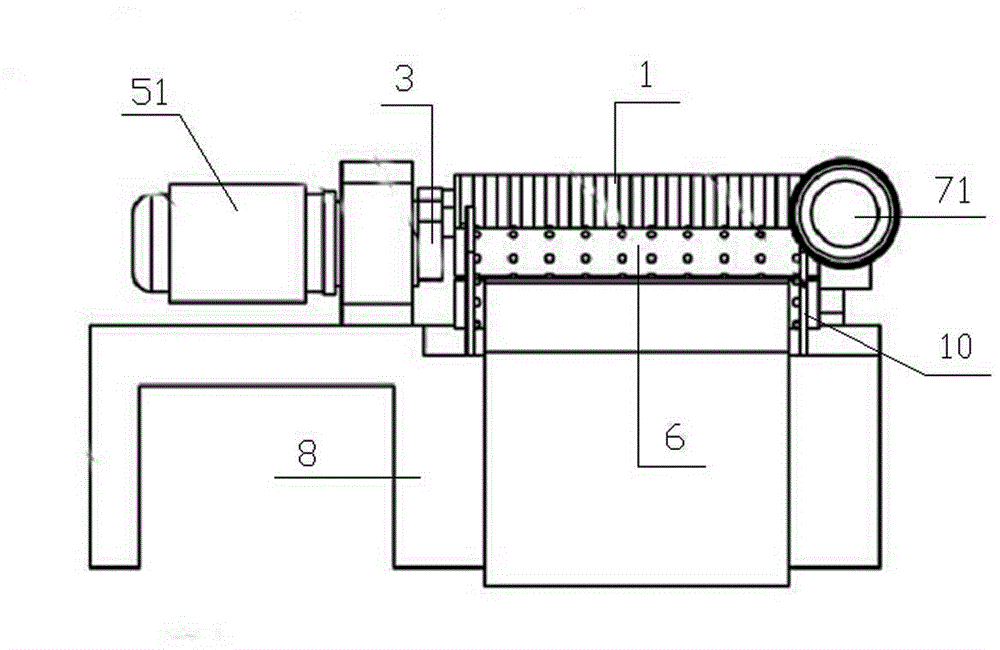

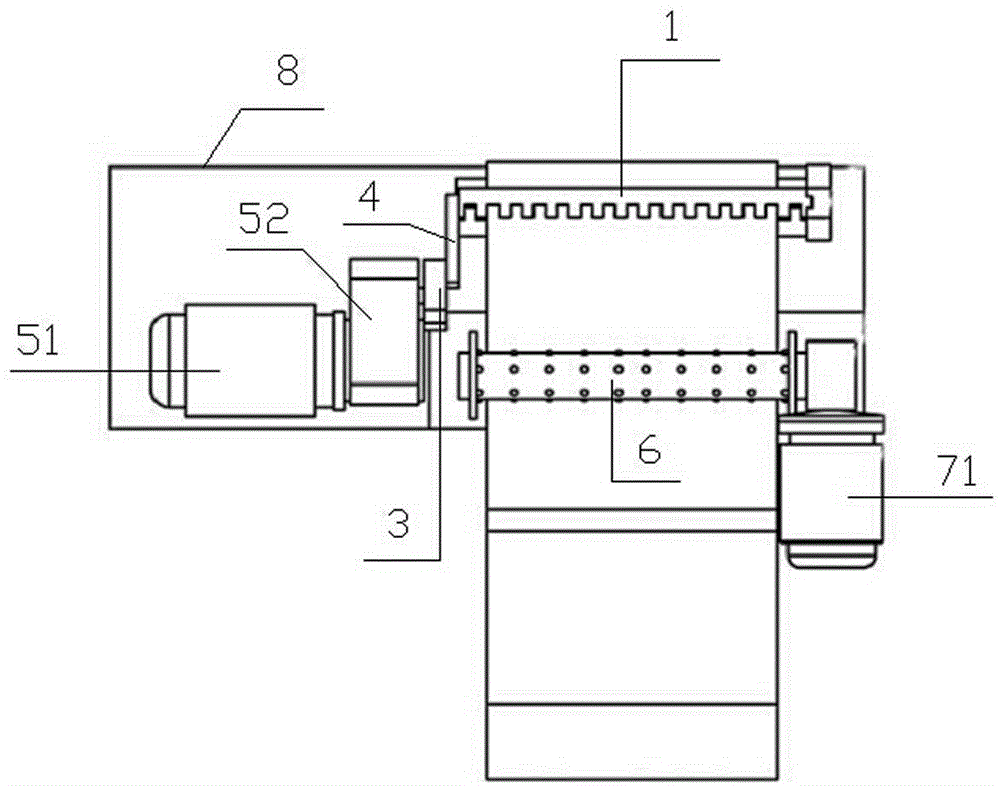

[0024] Example : A kind of parallel cutting crusher, as shown in the figure, comprises upper cutter group 1, lower cutter group 2, cam 3, connecting rod 4, cutter group power unit, pressure roller 6, pressure roller power device and frame 8. The knife group power unit and the lower knife group are fixed on the frame 8, and the upper knife group 1 is movable up and down on the frame 8 through the guide rail 9, and the upper knife group 1 and the lower knife group 2 are in a shear fit state. The cam 3 is connected to the power unit of the knife group, one end of the connecting rod 4 is eccentrically hinged with the cam 3 (actually the function of the eccentric wheel), the other end of the connecting rod 4 is hinged with the upper knife group 1, and the power unit of the knife group drives the cam 3 rotates, and the cam 3 drives the upper knife group 1 to perform a shearing movement relative to the lower knife group 2 through the connecting rod 4; other equivalent mechanisms can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com