automatic fish feeder

A fish feeding machine and automatic technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of increasing manual pressure, and achieve the effects of reducing waste rate, solving sedimentation and unevenness, and high efficiency filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

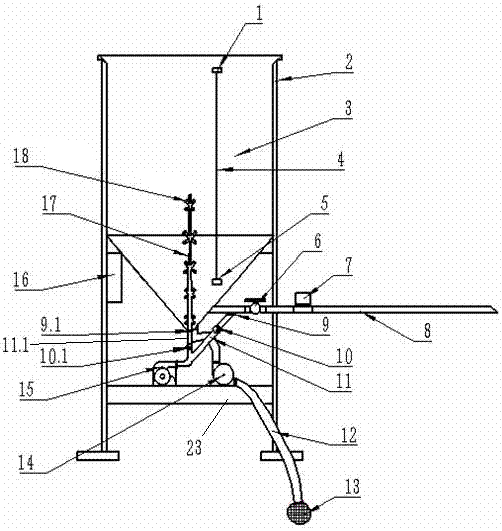

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

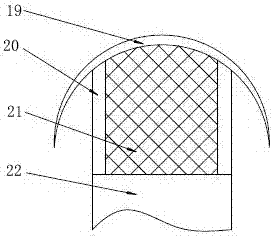

[0029] The automatic fish feeding machine comprises a support frame 2 and a hopper 3, the hopper 3 is arranged on the support frame 2, a crosspiece 23 is arranged on the support frame below the hopper, and a water pump 14 and an air pump 15 are arranged on the crosspiece 23; the hopper center is vertical Set the air spray column 17, the lower end of the air spray column 17 is connected to the air outlet of the air pump through the first air pipe 11.1, and the first air pipe is sequentially provided with the first air outlet valve 10.1 and the first one-way valve 9.1 from bottom to top to control the outlet of the first air pipe. Gas volume and on-off, a number of nozzles 18 are arranged on the circumference of the spray column 17 from top to bottom, and the fish feed is mixed by spraying air. The nozzle is composed of a nozzle cap 19, a nozzle cap column 20, a protective ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com