Valve arrangement

A technology of valve device and driving device, which is applied in the direction of valve device, valve operation/release device, valve details, etc., and can solve problems such as damage to operating performance and large dead point volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

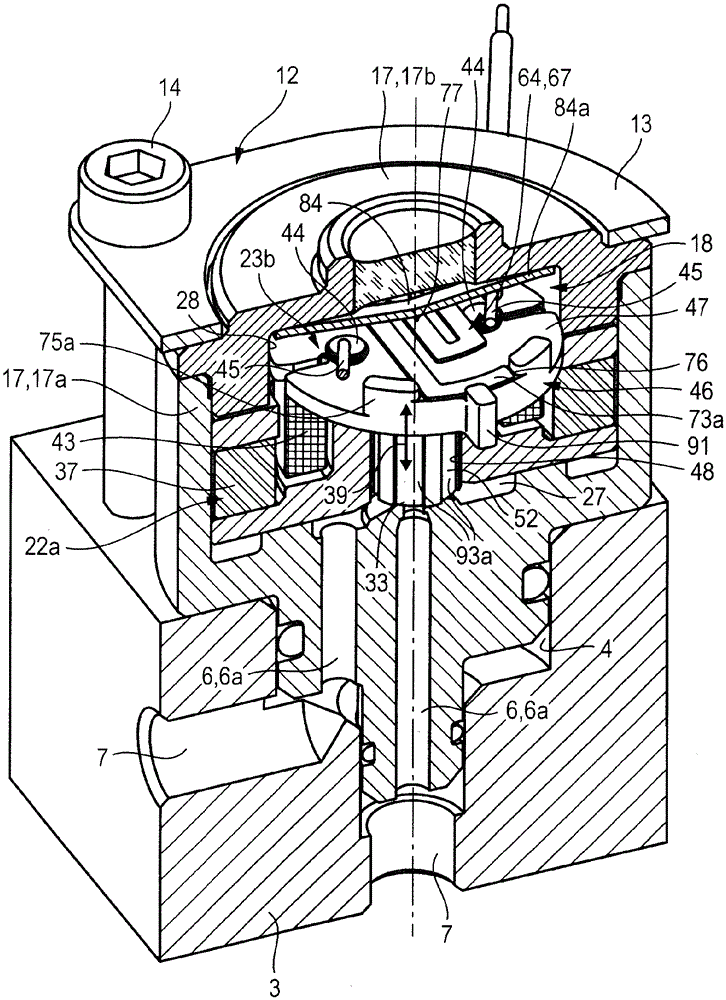

[0037] The valve device, which is identified in its general aspect with the reference number 1 , serves to control the flow of a fluid, in particular a gaseous fluid, and here preferably compressed air. However, the valve arrangement can also be used to control liquid media.

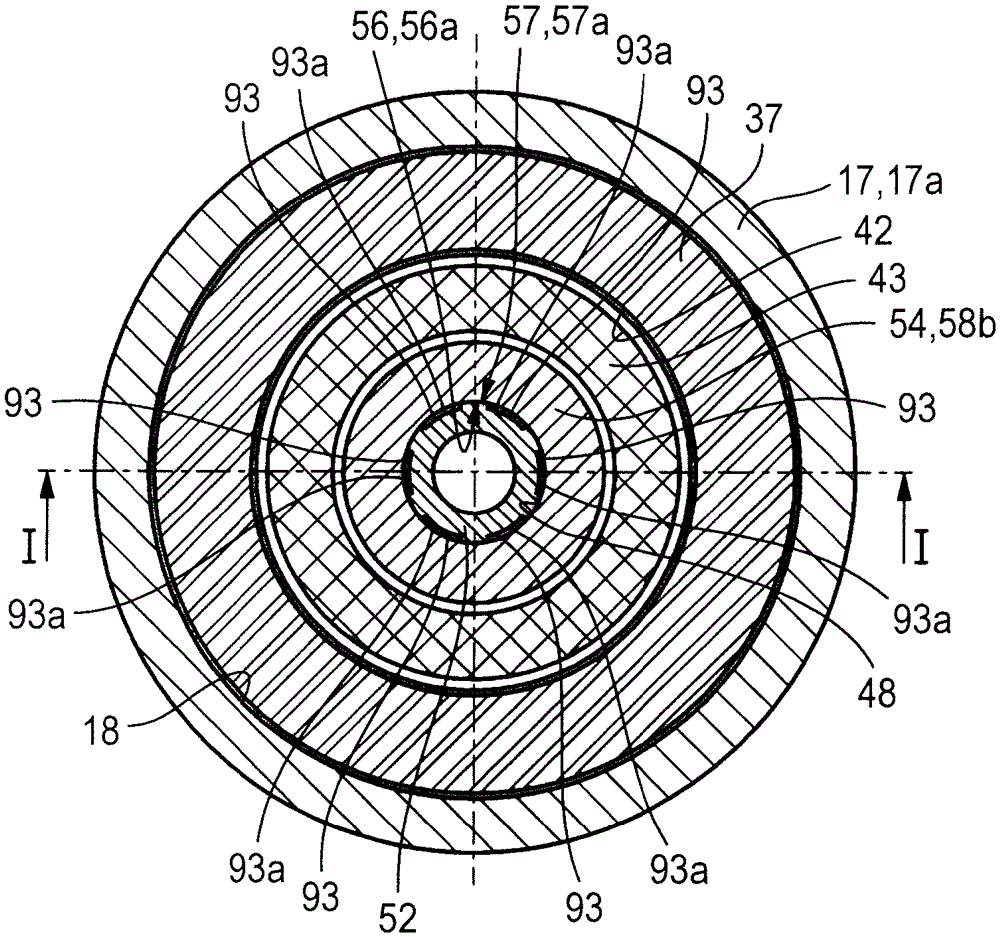

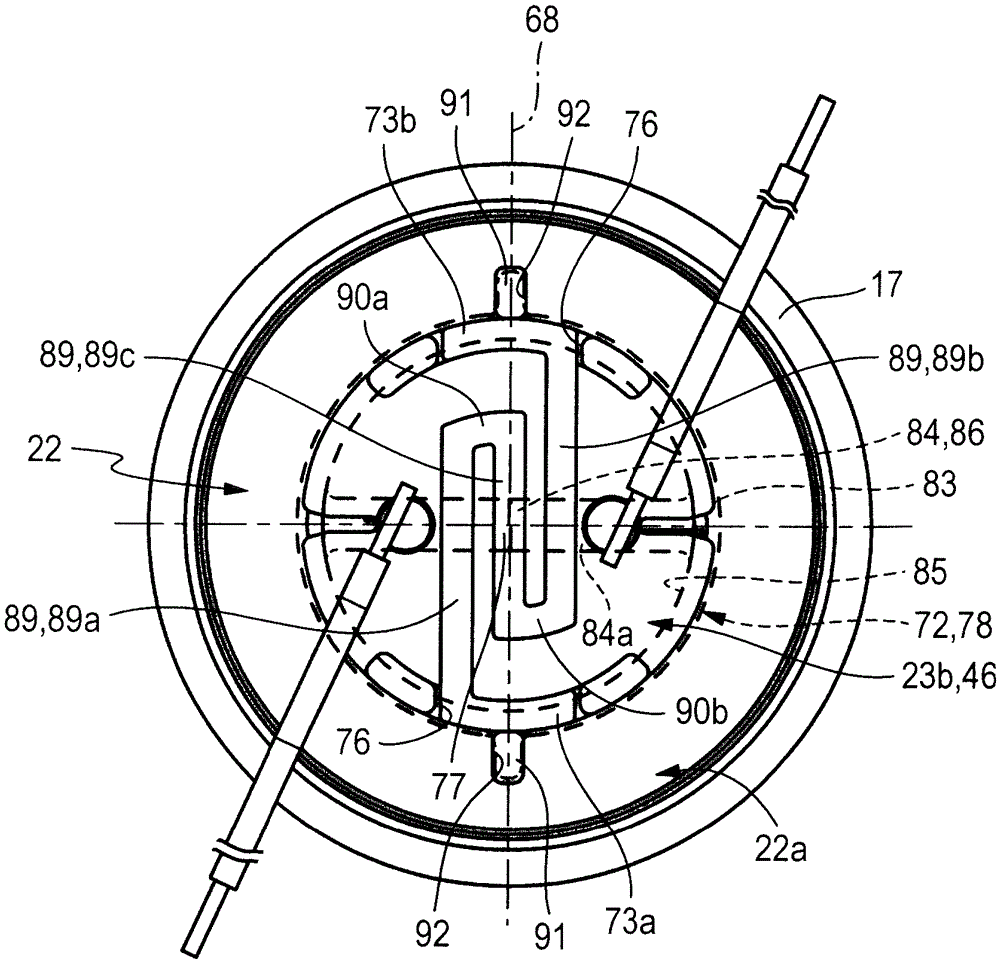

[0038] The valve device 1 has a valve unit 2 which can be used alone or preferably in combination with a connecting body 3 with which it can form a subassembly. The connecting body 3 has a blind hole-shaped receptacle 4 , into which the valve unit 2 can be inserted in a sealed manner in the manner of a bullet casing with a seat section 5 . figure 1 and figure 2 The valve device 1 is shown in the joined state of the subassembly consisting of the valve unit 2 and the connecting body 3 .

[0039] A plurality of valve channels 6 extend in the valve unit 2 . The valve channels 6 respectively communicate with one of a plurality of connecting channels 7 , which pass through the connecting body 3 . Each con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com