Method for the industrial production of flour from lipid-rich microalga biomass with no "off-notes" by controlling the oxygen availability

A biomass and utilization technology, applied in biochemical equipment and methods, specific-purpose bioreactor/fermenter, biomass post-treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

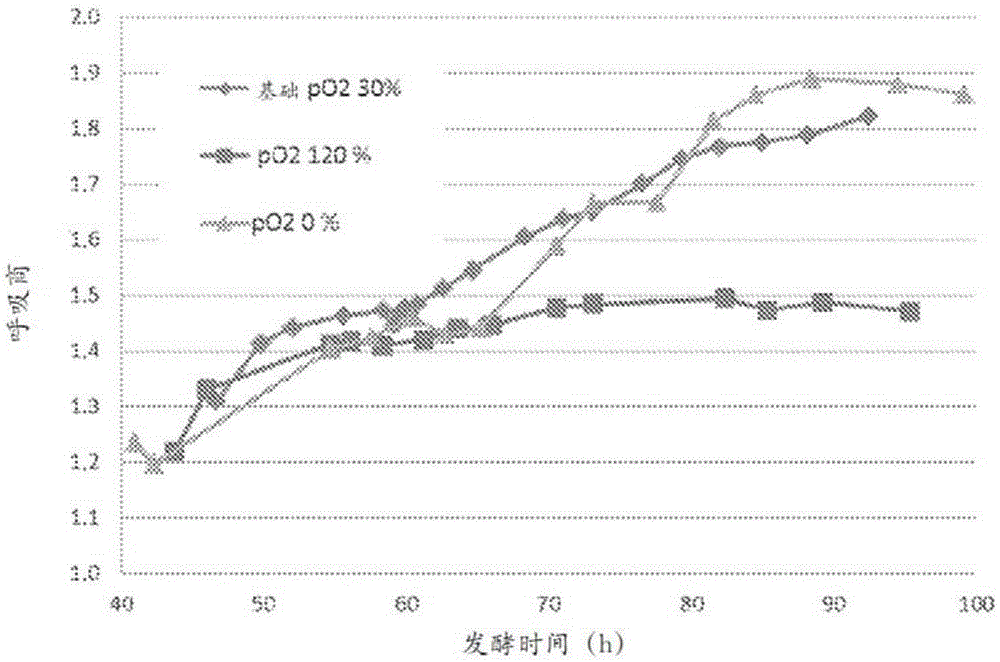

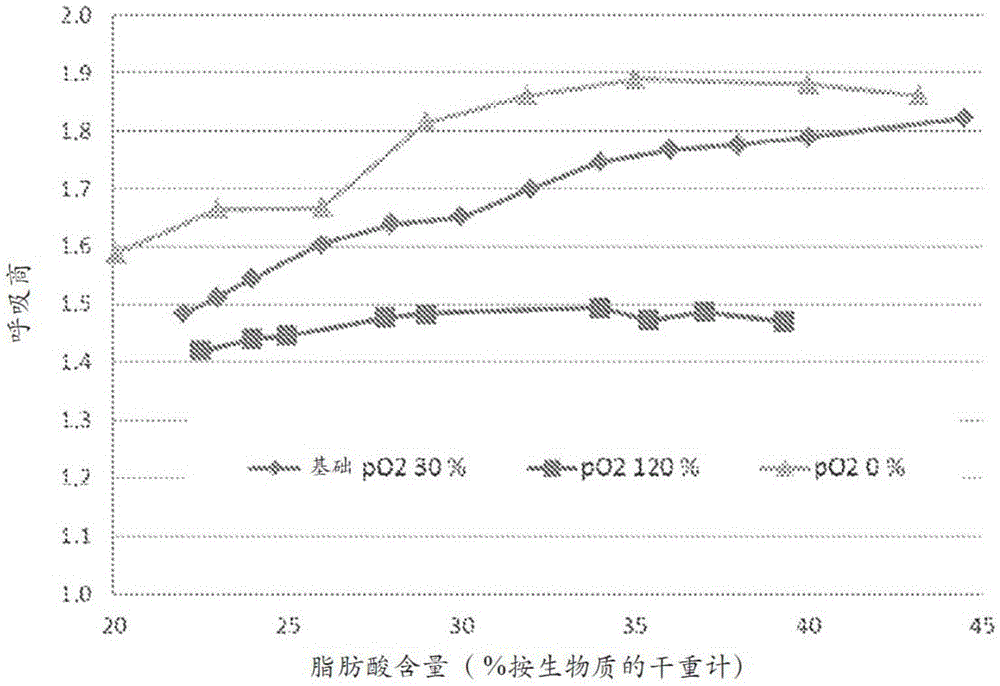

[0138] Example 1: Production of lipid-rich Chlorella protothecoides - controlled oxygenation

[0139] The algal species used is Chlorella protothecoides UTEX250

[0140] pre-culture :

[0141] - 500 ml medium in a 2 l Erlenmeyer flask (Erlenmeyer flask);

[0142] -Composition of the culture medium:

[0143] Table 1.

[0144]

[0145]

[0146] Incubation was performed under the following conditions: time: 72 h; temperature: 28° C.; shaking: 110 rpm (Infors Multitron incubator).

[0147] The preculture was then transferred to a Sartorius 301 fermenter.

[0148] Cultivation for biomass production:

[0149] The base medium is as follows:

[0150] Table 2.

[0151]

[0152]

[0153] The initial volume (Vi) of the fermentor was adjusted to 7 l after inoculation. A final volume of 15-20l is reached.

[0154] The parameters used to run the different tests are as follows:

[0155] table 3.

[0156]

[0157] When the residual concentration of glucose fell ...

Embodiment 2

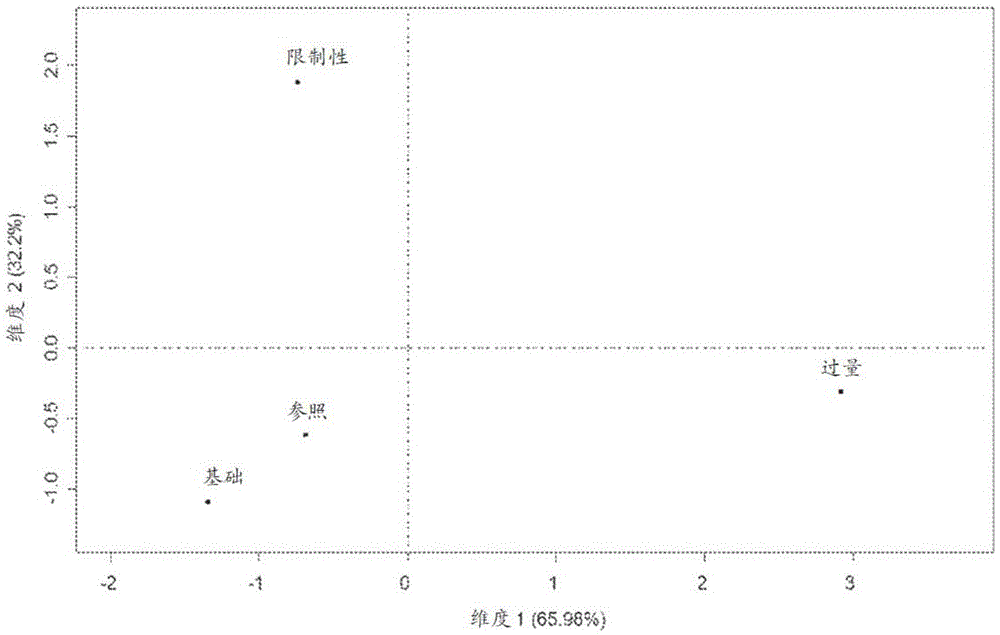

[0179] Example 2: Sensory Evaluation of 3 Batches Produced in Example 1

[0180] In this example, the applicant company proposes to determine the organoleptic quality of microalgal flour prepared from 3 batches produced in Example 1, which have been ground and dried according to the method described in patent application WO2010 / 12093 from Said flour made from biomass.

[0181] In French Patent Application No. 1356113, the applicant company defined a very simple tasting matrix that allows sensory evaluations similar to those obtained with far more complex and very different formulations (e.g. ice cream or brioche) sensory evaluation. The precision or accuracy of the assessment using this tasting matrix is much higher than that performed using a simple aqueous solution, which has proven unable to predict the organoleptic qualities of, for example, microalgal flour compositions in ice cream.

[0182] Thus, the microalgal flour tasting composition includes:

[0183] - 7% co...

Embodiment 3

[0232] Embodiment 3: Different from the 3 batches of the microalgal flour composition obtained from Example 1 Analysis of Volatile Organic Compounds (VOCs) Related to Sensory Classification of Acceptable Abnormal Characteristics

[0233] To carry out the SPME / GC-MS analysis of 3 batches of microalgal flour compositions obtained from the biomass produced in Example 1, the method was carried out as described below.

[0234] A test sample of 3 g aliquots was introduced into a sealed SPME flask (20 ml) and incubated at 60°C for 15 min, and then at 60°C using DVB / CAR / PDMS (divinylbenzene / carboxan / polydimethylsiloxane Abbreviation for oxane, df50 / 30μm) SPME fiber extraction for 45min.

[0235] The extracted VOCs were desorbed in an injector of a TSQGC-MS system from Thermo Scientific and then separated on a CPwax52 (60m x 0.25mm, 0.25μm) column using helium at 1.5ml / min.

[0236] The temperature program is as follows: keep at 50°C for 3 minutes, then program the temperature up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com