Manufacturing method of color membrane substrate

A production method and technology for color filter substrates, which are applied in nonlinear optics, instruments, optics, etc., can solve the problems of product quality degradation, affecting the display effect of the picture, and impurity of the picture, saving process technology and materials, and improving product display. Quality, the effect of improving product perspective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

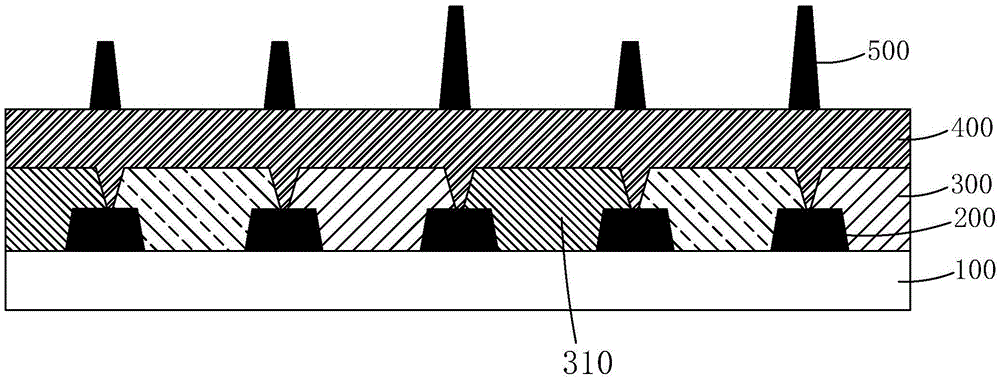

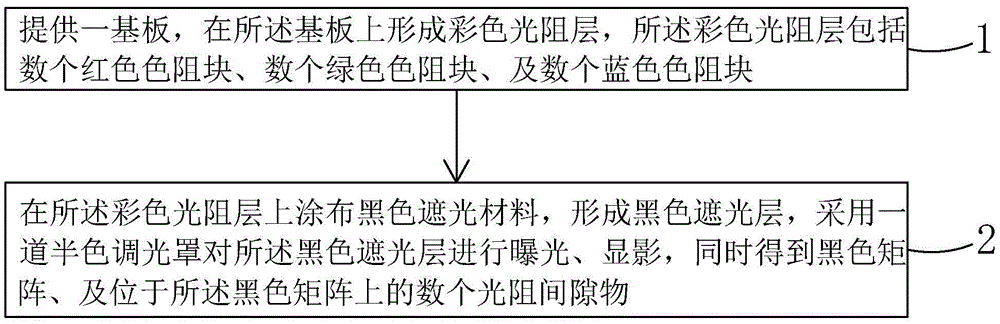

[0047] see image 3 , which is the first embodiment of the manufacturing method of the color filter substrate of the present invention, specifically includes the following steps:

[0048] Step 1, such as Figure 4-5 As shown, a substrate 10 is provided, and a color photoresist layer 20 is formed on the substrate 10. The color photoresist layer 20 includes several red color resist blocks 21, several green color resist blocks 22, and several blue color resist blocks. Block 23.

[0049] Specifically, the substrate 10 is a transparent substrate, preferably a glass substrate.

[0050] Specifically, the color photoresist layer 20 may also include several white color resist blocks. Further, the manufacturing sequence of the red color-resisting block 21 , several green color-resisting blocks 22 , several blue color-resisting blocks 23 , and several white color-resisting blocks is not limited, and can be selected according to needs.

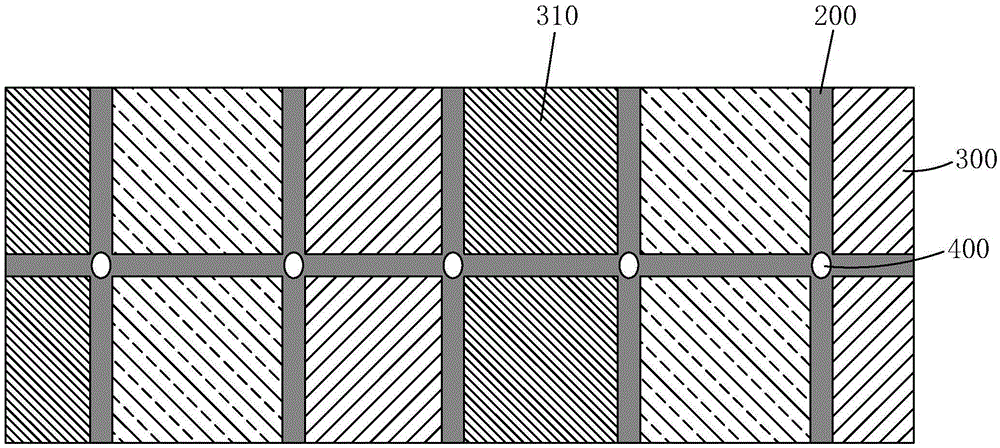

[0051] Step 2, such as Figure 6-8 As shown, a...

no. 2 example

[0056] see Figure 9 , which is the second embodiment of the manufacturing method of the color filter substrate of the present invention, specifically includes the following steps:

[0057] Step 1, such as Figure 10-11 As shown, a substrate 10 is provided, and a color photoresist layer 20 is formed on the substrate 10 using a halftone mask process, and the color photoresist layer 20 includes several red color resist blocks 21 and several green color resist blocks 22 , and several blue color resist blocks 23, while the color photoresist layer 20 has several transverse grooves 25 and several longitudinal grooves 26, and the several transverse grooves 25 and several longitudinal grooves 26 are located in phase The junction of adjacent color resistance blocks 21 / 22 / 23.

[0058] Specifically, the substrate 10 is a transparent substrate, preferably a glass substrate.

[0059] Specifically, the color photoresist layer 20 may also include several white color resist blocks. Furthe...

no. 3 example

[0066] see Figure 15 , which is the third embodiment of the manufacturing method of the color filter substrate of the present invention, specifically includes the following steps:

[0067] Step 1, such as Figure 16-17 As shown, a substrate 10 is provided, a first black matrix 70 is formed on the substrate 10, a color photoresist layer 20 is formed on the black matrix 20 and the substrate 10, and the color photoresist layer 20 includes several red color Resistance block 21 , several green color resistance blocks 22 , and several blue color resistance blocks 23 .

[0068] Specifically, the substrate 10 is a transparent substrate, preferably a glass substrate.

[0069] Specifically, the first black matrix 70 is arranged corresponding to the junction of the adjacent color resist blocks 21 / 22 / 23 on the color photoresist layer 20 .

[0070] Preferably, the color photoresist layer 20 may also include several white color resist blocks. Further, the manufacturing sequence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com