Biomass height difference combustion chamber

A combustion chamber and biomass technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems that the combustion efficiency needs to be further improved, and achieve the effects of heat exchange, efficiency improvement, and particle temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

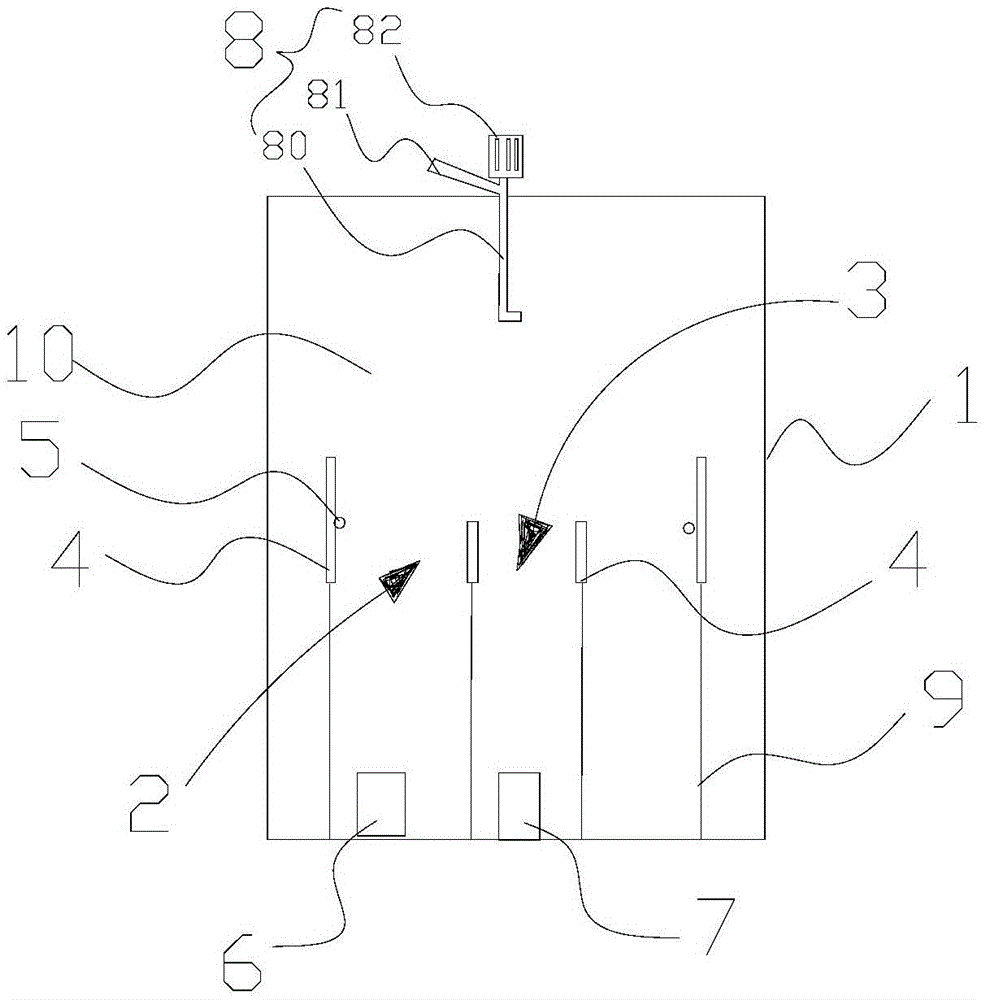

[0022] A biomass combustion chamber with height difference, comprising a combustion chamber shell 1, a feeding device 8, a main bed 2, an auxiliary bed 3, a buried pipe 5, a main bed air supply device 7, and a auxiliary bed air supply device 6; The chamber housing includes an internal cylindrical chamber, in the middle of the cylindrical chamber is provided with N concentrically arranged annular partitions 4, and the N annular partitions divide the central part of the cylindrical chamber into an inner circle. The bottoms of the circular main bed and the N annular auxiliary beds are connected to each other; the height of the N partitions rises stepwise from the axis of the cylindrical chamber from the inside to the outside Where N is an integer between 1-5; the feeding device is used to spray the biomass to be burned at the top of the cylindrical chamber and the area directly above the circular main bed; the auxiliary bed gives There are N wind devices; the number of buried pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com