Device for detecting air density in natural gas pipeline

A natural gas pipeline and gas density technology, which is applied in the direction of measuring devices, pipeline systems, gas/liquid distribution and storage, etc., can solve problems such as unfavorable popularization and application of multi-point real-time monitoring systems, high cost of detection methods, and complicated operations, etc., to achieve Effect of avoiding natural gas leakage, low cost, high accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

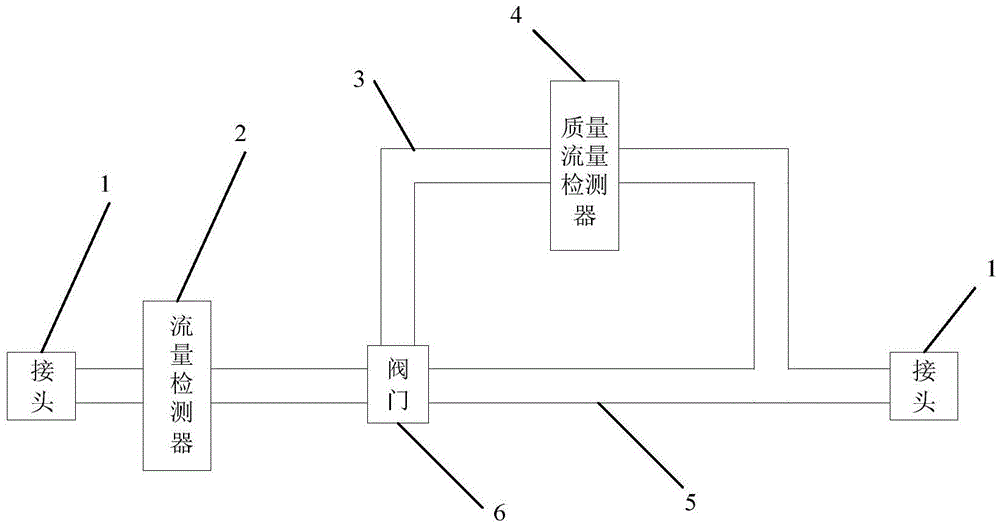

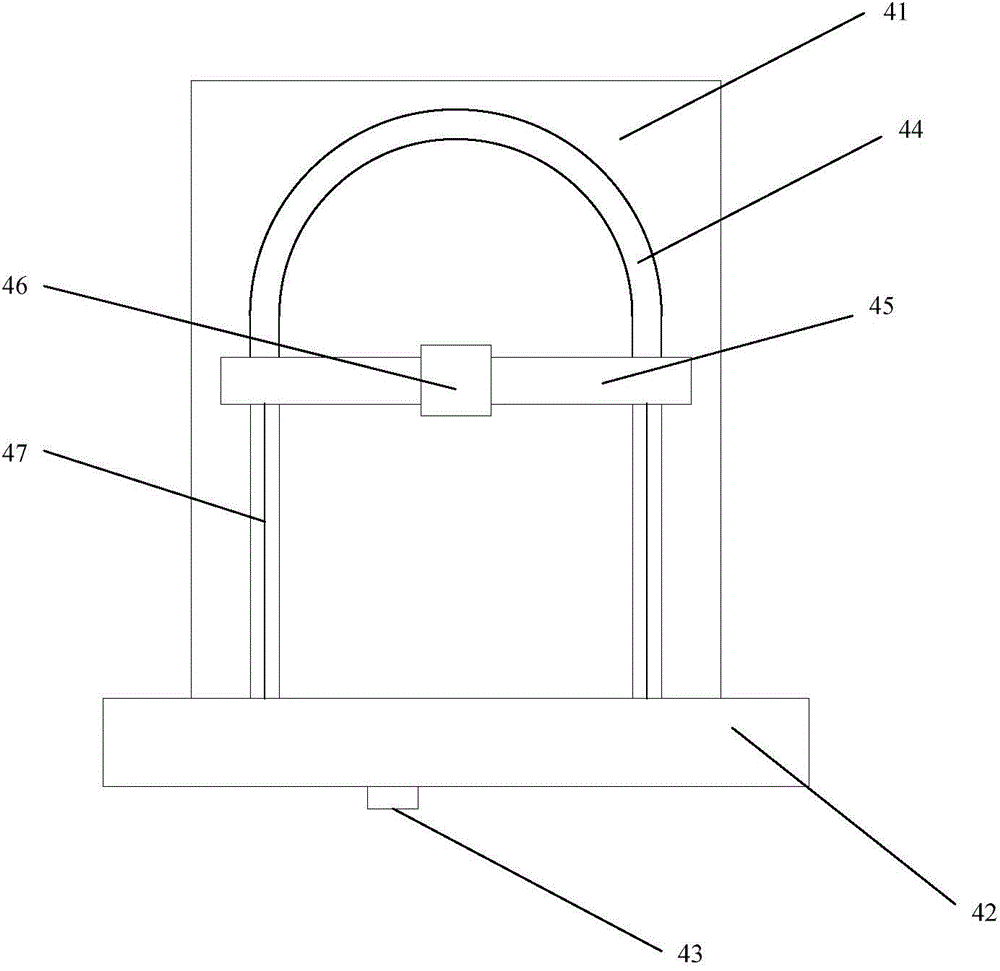

[0017] Such as figure 1 , 2 As shown, a device for detecting gas density in a natural gas pipeline includes: a joint 1, a flow detector 2, a straight pipe section 5, a valve 6, a detection pipe section 3, and a mass flow detector 4;

[0018] The joint 1 is arranged at both ends of the straight pipe section 5, and is used to connect the pipeline to be tested;

[0019] The flow detector 2 and the valve 6 are sequentially connected through the straight pipe section 5;

[0020] One end of the detection pipe section 3 is set at the connection between the valve 6 and the straight pipe section 5, and the other end communicates with the straight pipe section 5. When there is gas passing through the straight pipe section, the valve 6 can selectively let the gas flow in according to the signal sent by the flow detector 2. Detect pipe section 3 or subsequent straight pipe section 5;

[0021] The mass flow detector 4 is arranged inside the detection pipe section 3 for detecting the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com