Gravity balance difference pumping unit

A technology of gravity balance and pumping unit, which is applied in the direction of brake actuators, production fluids, boreholes/well components, etc., can solve the problems of unsatisfactory energy saving effects, and achieve safe and reliable parameter adjustment operations, low energy consumption, and reduced The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

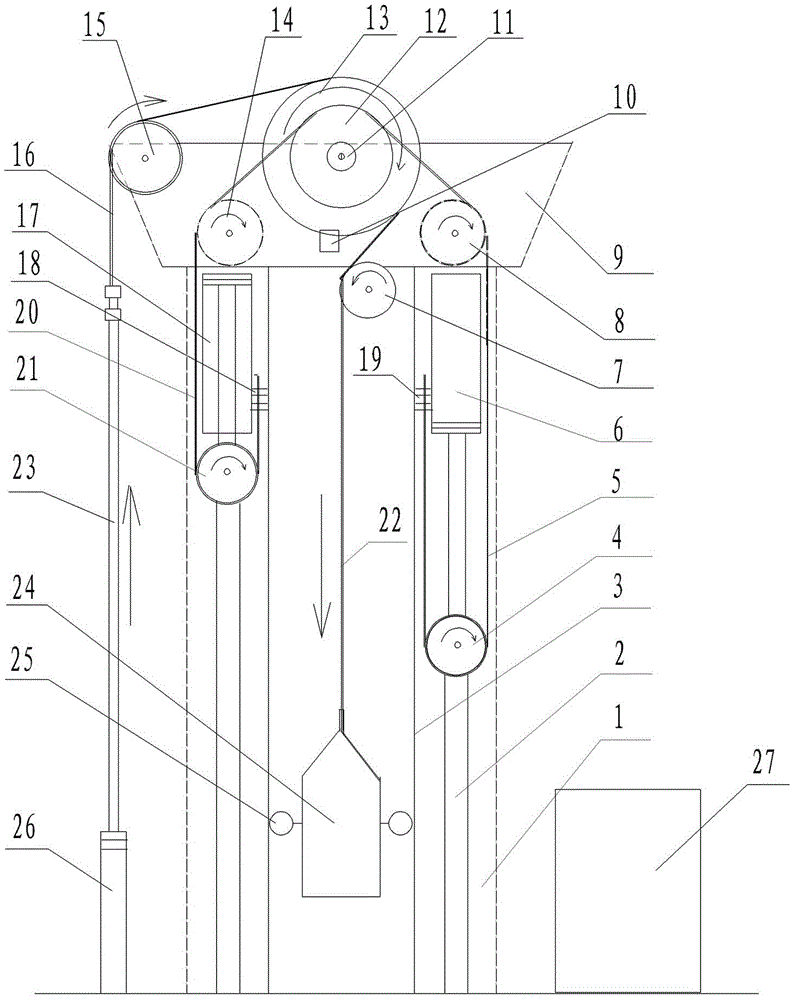

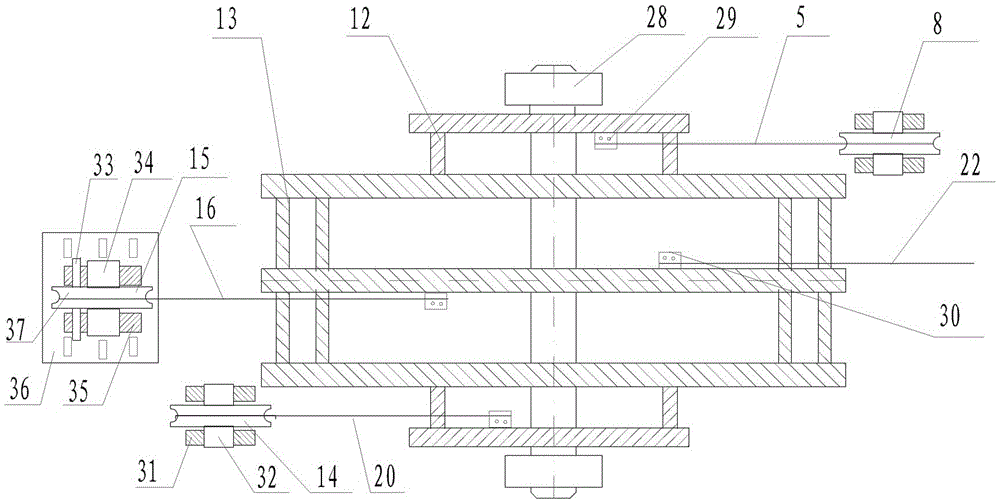

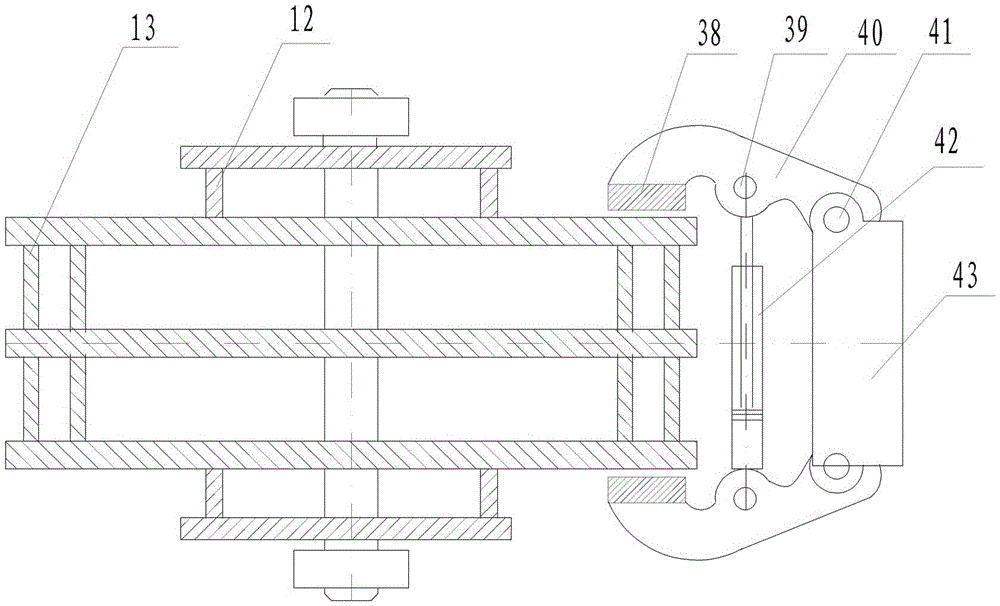

[0038]Pumping unit with poor gravity balance, including frame 1, upper platform 9 fixed on the top of the frame, first driving cylinder 6, second driving cylinder 17, gravity combination drum, driving cylinder pull rope, counterweight pull rope, and sucker rod 23 , counterweight iron 24, hydraulic braking device 10, hydraulic pump station 27. The first driving cylinder 6 and the second driving cylinder 17 are respectively installed on the front and rear sides of the frame 1, the first driving cylinder 6 and the second driving cylinder 17 are connected to the plunger pump of the hydraulic pump station 27 through the oil circuit, the first The piston rod of the drive cylinder 6 is connected with the first movable pulley 4, and the piston rod of the second drive cylinder 17 is connected with the second movable pulley 21. The first movable pulley 4 and the second movable pulley 21 are connected to the front and rear sides of the frame 1 respectively. On the movable pulley slideway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com