Gable waterproof structure

A waterproof structure and gable technology, applied in the direction of roof drainage, building structure, roof, etc., can solve the problems such as the falling off of the gable trim 32, and achieve the effect of reducing wind damage, reducing the area affected by wind, and connecting strong and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

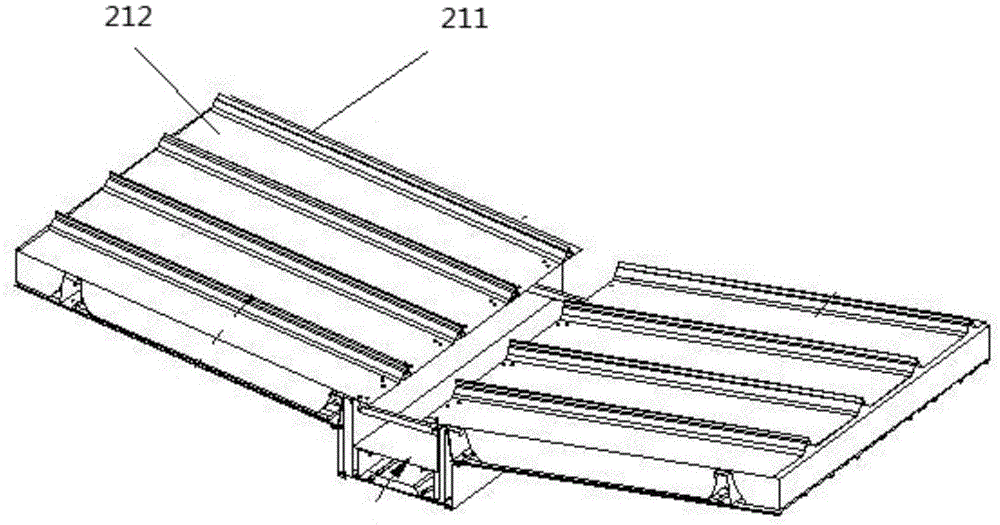

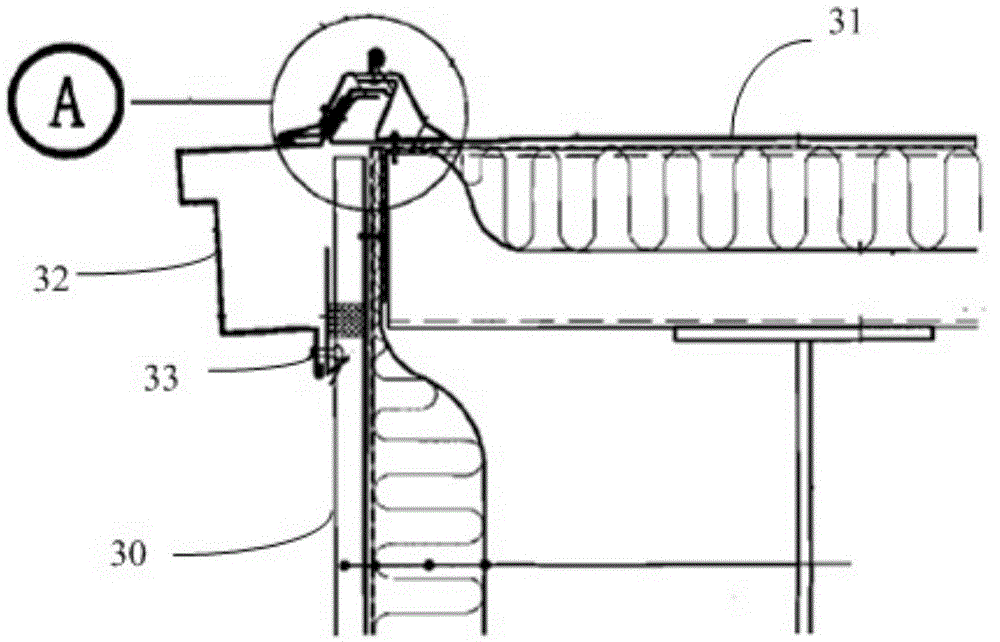

[0042] Figure 5 It is the schematic diagram of the gable waterproof structure of the embodiment of the present invention, as Figure 5 As shown, the embodiment of the present invention provides a gable waterproof structure, including:

[0043] The gable bending angle steel 51 is fixed on the inner side of the gable 50;

[0044] Angle steel bracket 52, the first end is fixed on the said gable bending angle steel 51, and the second end protrudes to the outside of said gable 50 through the top of said gable 50;

[0045] The sliding bracket 53 is slidably installed on the gable bending angle steel 51;

[0046] The upper flashing part 54 is fixedly installed on the sliding bracket 53 and connected with the roof panel 55 to cover the top of the gable wall 50;

[0047] The side flashing part 56 is located below the upper flashing part 54 and is fixedly installed on the angle steel bracket 52 .

[0048] It can be seen that in the embodiment of the present invention, there are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com