An adaptive sliding rubber bearing and its replacement method

A rubber bearing, self-adaptive technology, applied in building maintenance, building components, shockproof, etc., can solve the problems of inconvenient replacement of bearings, troublesome process, and many steps, etc., to meet the needs of engineering use, easy operation, and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

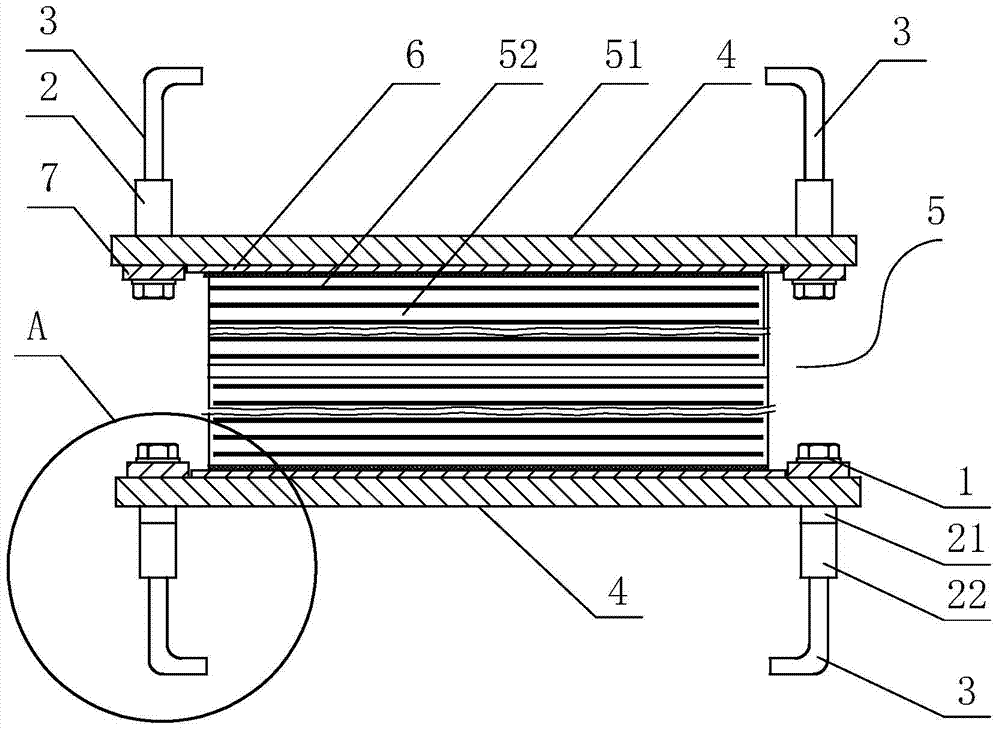

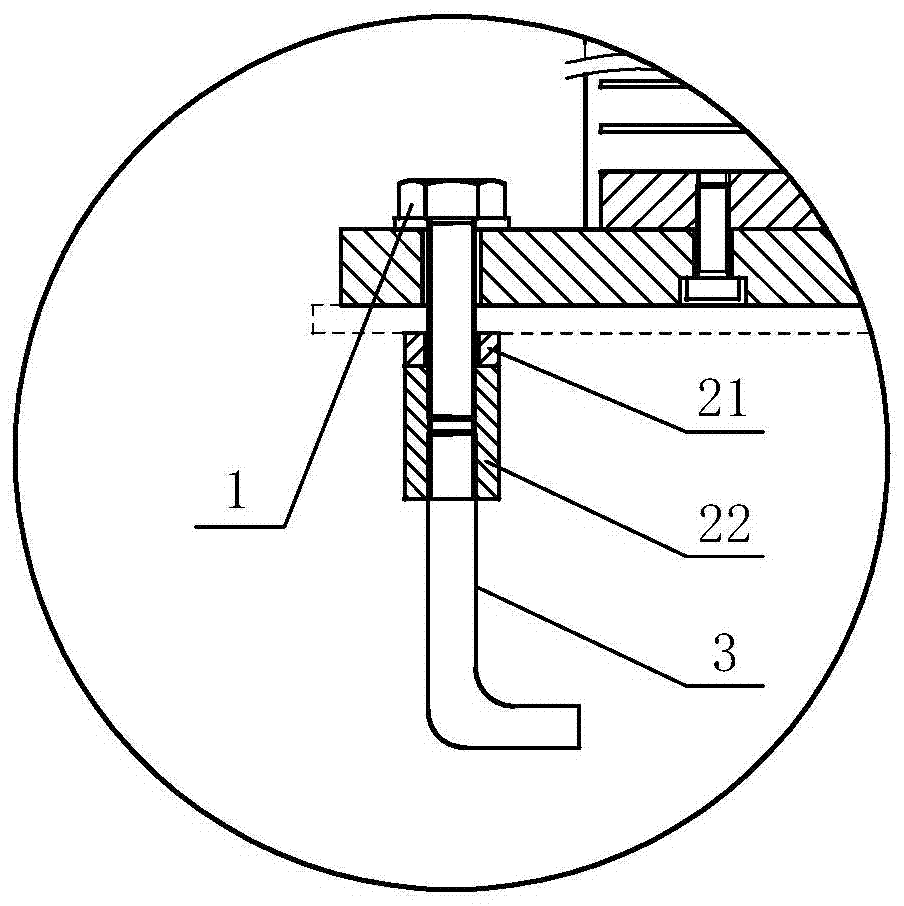

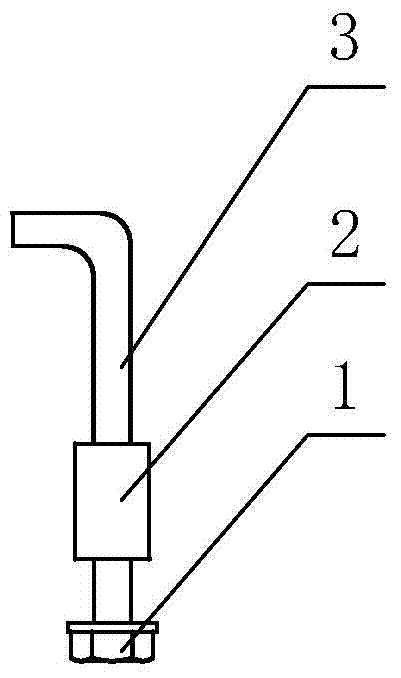

[0032] Such as figure 1 As shown, an adaptive sliding rubber bearing includes a bearing body 5, an outer connecting steel plate 4 and a connecting fastener installed on the outer connecting steel plate, and the connecting fastener includes an anchor rib 3, a sleeve 2 and a connecting Bolt 1, the sleeve of the connecting fastener installed on the upper and outer connecting steel plate is a traditional sleeve 2, and the connecting bolt of the connecting fastener passes through the upper and outer connecting steel plate 4 and is threadedly connected with half of the sleeve 2, The outer half of the sleeve 2 is connected with the anchor rib 3;

[0033] The sleeve of the connecting fastener installed on the lower outer connecting steel plate includes a movable sleeve 21 and a fixed sleeve 22, and the connecting bolt of the connecting fastener passes through the lower outer connecting steel plate 4 of the support, the movable sleeve 21 and the fixed sleeve The inner half of the cyli...

Embodiment 2

[0036] Such as Figure 4 As shown, an adaptive sliding rubber bearing has the same basic structure as that of Embodiment 1, including a bearing body 5, an outer connecting steel plate 4 and connecting fasteners installed on the outer connecting steel plate, and the connecting fasteners include Anchor rib 3, sleeve 2 and connecting bolt 1,

[0037] The difference is: the sleeve of the connecting fastener installed on the lower outer connecting steel plate is a traditional sleeve 2, and the connecting bolt of the connecting fastener passes through the lower outer connecting steel plate 4 and is threaded to the inner half of the sleeve 2 , the outer half of the sleeve 2 is connected to the anchor rib 3;

[0038] The sleeve of the connecting fastener installed on the upper outer connecting steel plate includes a movable sleeve 21 and a fixed sleeve 22, and the connecting bolt of the connecting fastener passes through the upper outer connecting steel plate 4 of the support and the...

Embodiment 3

[0041] Embodiment 1 A method for replacing an adaptive sliding rubber bearing, comprising the following steps:

[0042] 1) Unscrew and take out the connecting bolts of the outer connecting steel plate under the rubber bearing;

[0043] 2) Chisel off the concrete on the layer where the movable sleeve is located together with the movable sleeve;

[0044] 3) Unscrew the connecting bolts of the outer connecting steel plate on the rubber bearing, remove the rubber bearing, and put a new rubber bearing in;

[0045] 4) Install the connecting bolts of the outer connecting steel plate on the support, put the movable sleeve in the lower part of the connecting steel plate under the support, and then screw in the connecting bolts;

[0046] 5) After the new support is in place and the level is adjusted, tighten the connecting bolts at the upper and lower parts;

[0047] 6) Finally, the concrete pouring of the movable sleeve layer is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com