Chemosynthetic water-soluble fertilizer and production method and application thereof

A water-soluble fertilizer, chemical synthesis technology, applied in the direction of alkaline orthophosphate fertilizer, application, inorganic fertilizer, etc., can solve the problems of poor water solubility and absorption effect, incomplete dechlorination of potassium chloride, unstable physical and chemical properties, etc. , to achieve the effects of less water insoluble matter, reduced production processes, and improved appearance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

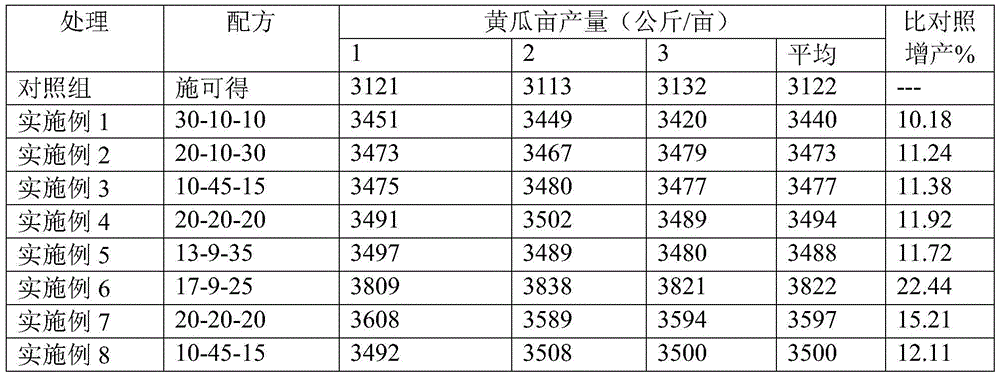

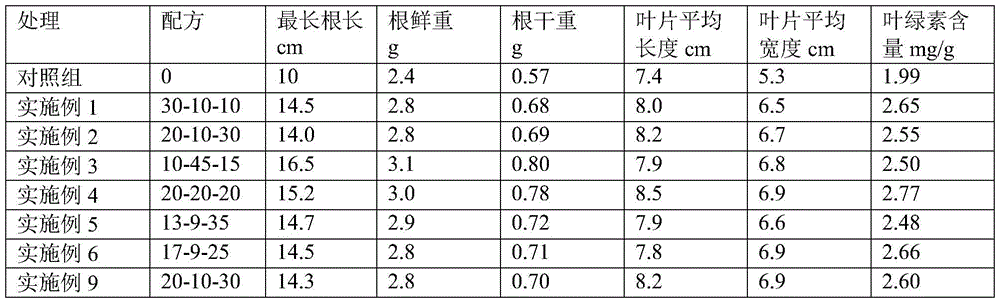

Examples

Embodiment 1

[0043] Technical indicators: 30-10-10+TE0.3

[0044] Raw materials: 175kg of ammonium dihydrogen phosphate, 575kg of urea, 225kg of potassium nitrate, 10kg of sodium octaborate tetrahydrate, 5.5kg of zinc sulfate heptahydrate, 6kg of potassium hydroxide, and 3.5kg of sodium citrate.

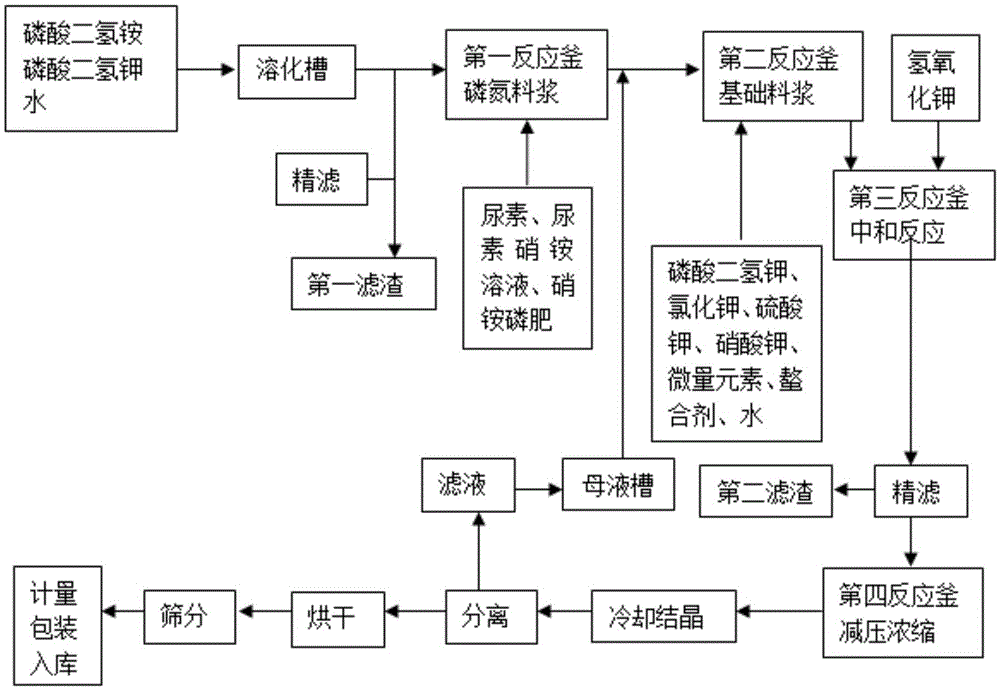

[0045] Such as figure 1 Shown, the production method of the chemically synthesized water-soluble fertilizer of present embodiment, comprises the steps:

[0046] Step 1, adding ammonium dihydrogen phosphate into the dissolving tank, adding an appropriate amount of water to make the water content of ammonium dihydrogen phosphate 35%, and heating it to 90°C, finely filtering to obtain phosphorus fertilizer slurry and the first filter residue;

[0047] Step 2, pump the phosphorus fertilizer slurry into the first reaction kettle, add urea, heat to keep the temperature of the first reaction kettle at 90°C, and react for 2 hours to obtain phosphorus and nitrogen slurry;

[0048] Step 3. Add potassium ...

Embodiment 2

[0056] Technical indicators: 20-10-30+TE0.2

[0057] Raw materials: Potassium dihydrogen phosphate 210kg, urea 260kg, potassium nitrate 510kg, sodium octaborate tetrahydrate 5kg, zinc sulfate heptahydrate 6kg, potassium hydroxide 5kg, sodium citrate 4kg.

[0058] Such as figure 1 Shown, the production method of the chemically synthesized water-soluble fertilizer of present embodiment, comprises the steps:

[0059] Step 1, adding potassium dihydrogen phosphate into the dissolving tank, adding an appropriate amount of water to make the water content of potassium dihydrogen phosphate 25%, heating it to 95°C, and finely filtering to obtain phosphorus fertilizer slurry and the first filter residue;

[0060] Step 2, pump the phosphorus fertilizer slurry into the first reactor, add urea, heat to keep the temperature of the first reactor at 95°C, and react for 1.5 hours to obtain the phosphorus and nitrogen slurry;

[0061] Step 3. Add potassium nitrate, sodium octaborate tetrahydra...

Embodiment 3

[0069] Technical indicators: 10-45-15+TE0.25

[0070] Raw materials: 580kg ammonium dihydrogen phosphate, 200kg potassium dihydrogen phosphate, 140kg potassium nitrate, 50kg urea, 10kg sodium octaborate tetrahydrate, 4kg zinc sulfate heptahydrate, 12kg potassium hydroxide, 4kg sodium citrate.

[0071] Such as figure 1 Shown, the production method of the chemically synthesized water-soluble fertilizer of present embodiment, comprises the steps:

[0072] Step 1. Add ammonium dihydrogen phosphate and potassium dihydrogen phosphate into the dissolving tank, add an appropriate amount of water to make the water content of ammonium dihydrogen phosphate and potassium dihydrogen phosphate 20%, heat it to 100°C, fine filter, Obtain phosphorus fertilizer slurry and the first filter residue;

[0073] Step 2, pumping the phosphorus fertilizer slurry into the first reactor, adding urea, heating to keep the temperature of the first reactor at 100°C, and reacting for 1 hour to obtain the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com