Multilayer storage and transport assembly line

A multi-layer storage and assembly line technology, applied in the field of transportation assembly line, can solve the problems of a large amount of labor and occupying a large inventory space, and achieve the effect of utilizing the workshop area, reducing transportation costs, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

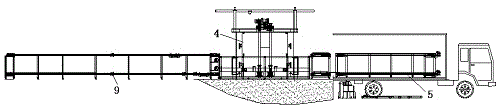

[0030] combine figure 1 , figure 2 with image 3 , a kind of multi-layer storage transport assembly line of the present embodiment, comprises loading area 5 and transport channel 6, and it also comprises buffer area 3, connecting area 4 and pallet storage area, one end of transport channel 6 is fixedly connected with pallet storage area, and the other One end is fixedly connected to the buffer area 3, the transport channel 6 is perpendicular to the pallet storage area, and the loading area 5 is connected to the buffer area 3 through the connecting area 4.

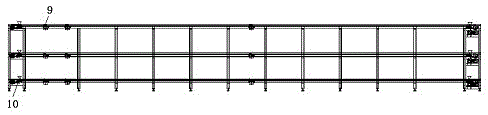

[0031] The pallet storage area is divided into storage A area 7 and storage B area 8. The storage A area 7 and the storage B area 8 both have three floors. A blocker 9 is also arranged in the middle of the length direction of the line transport chain in the area, and the distance between the two blockers 9 arranged before and after the exit of the pallet storage area is equal to the width of the pallet. A transfer mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com