Coal mine lifter patrol robot mechanism based on electromagnetic suckers

An electromagnetic sucker and robot technology, applied in the direction of manipulators, chucks, joints, etc., can solve the problems of damage to the paint protection layer, inflexible activities, and increased artificial risks, and achieve the effect of not being easily corroded, flexible in movement, and guaranteed in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

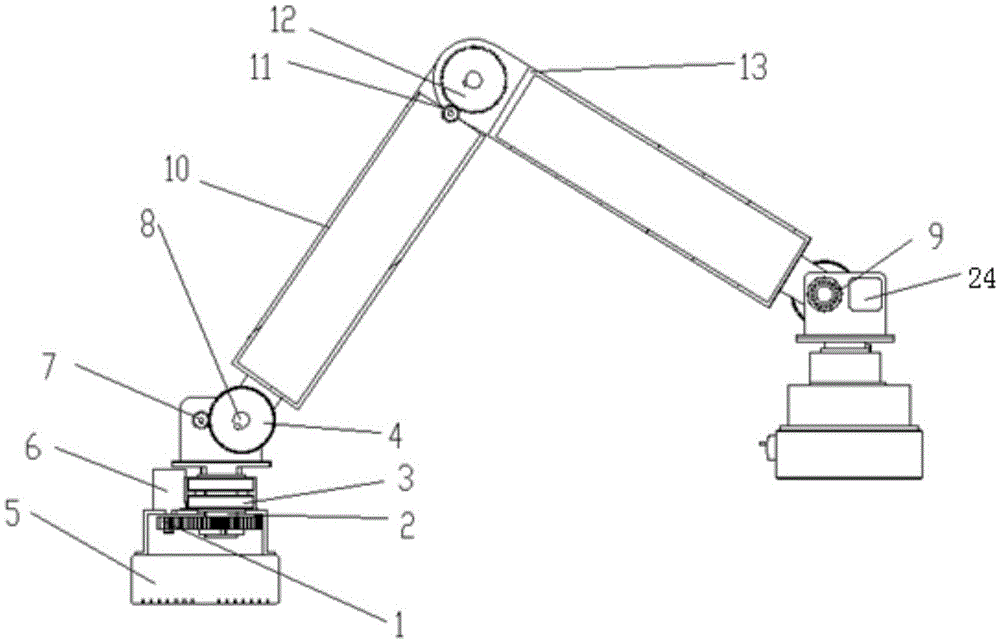

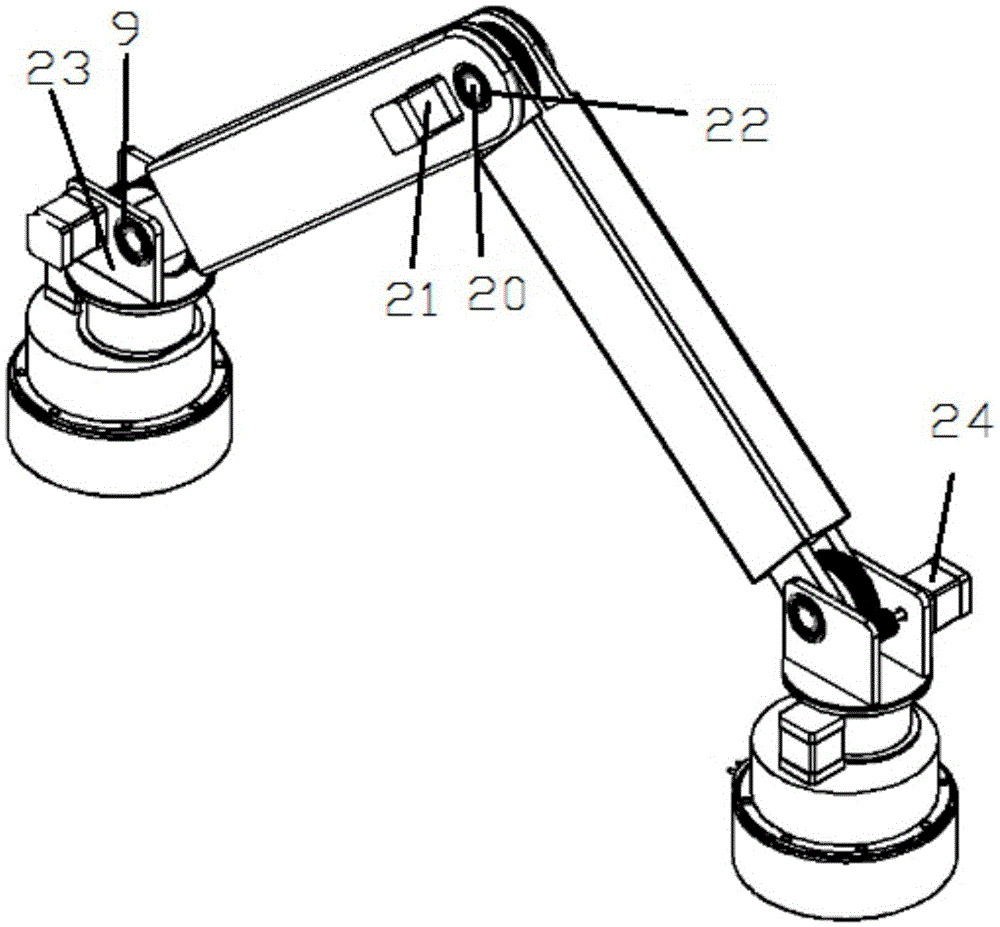

[0018] The iron frame climbing robot structure based on the electromagnetic chuck of the present invention mainly consists of two two-degree-of-freedom wrist structures, a climbing mechanical arm hinged with two two-degree-of-freedom wrist structures, and two two-degree-of-freedom wrist structures The bottom is respectively provided with electromagnetic chuck 5;

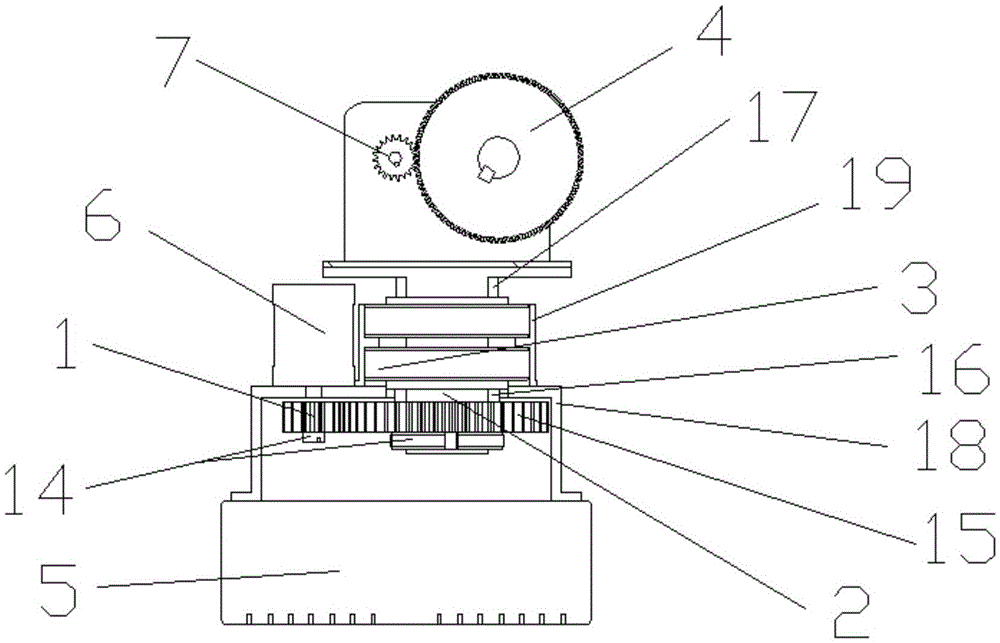

[0019] The two-degree-of-freedom wrist structure includes: rotary drive gear 1, rotary shaft 2, driven gear 4, electromagnetic chuck 5, stepping motor 6, drive gear 7, connecting shaft 8, deep groove ball bearing 9, rotary slave The moving gear 15, the gear end sleeve 16, the shaft end sleeve 17, the bottom connecting piece 18 and the bearing mounting piece 19; the bottom connecting piece 18 is provided on the upper surface of the electromagnetic chuck 5, and the stepping motor 6 and the bearing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com