A sedimentation tank device with a sedimentation wall

A sedimentation tank and inclined hole technology, applied in the feeding/discharging device of sedimentation tank, sedimentation separation, sedimentation tank, etc., can solve the maintenance difficulty of scraping and suction equipment, difficulty in uniform water distribution and water collection, and bottom sediment discharge Difficulties and other problems, to achieve the effect of simple structure, simple mechanism, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

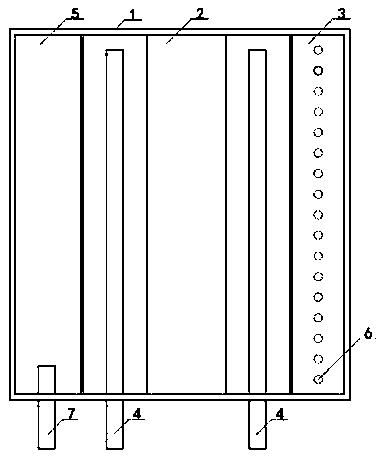

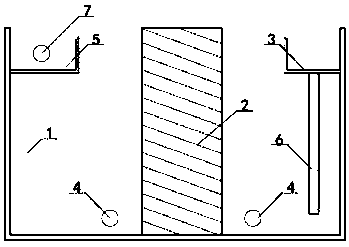

[0022] Such as figure 1 and figure 2 Said, a sedimentation tank device with a sedimentation wall, comprising a sedimentation tank 1, the two inner walls of the sedimentation tank 1 along the length direction are respectively provided with an inlet water distribution tank 3 and an outlet water collection channel 5, the sedimentation tank 1 In the middle along the length direction, a settling wall 2 with oblique holes installed on the bottom of the sedimentation tank 1 and separating the sedimentation tank 1 into two parts is arranged vertically. The sedimentation channel on both sides of the inclined hole sedimentation wall 2, the inclination direction of the sedimentation channel is from the side of the water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com