Method for evaluating fracturing property of shale based on rock debris microscopic characteristics

An evaluation method and cuttings technology, applied in material inspection products, soil material testing and other directions, can solve the problems of high experimental cost, low drilling and coring rate, long time consumption, etc., and achieve convenient and fast operation, high promotion value, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments:

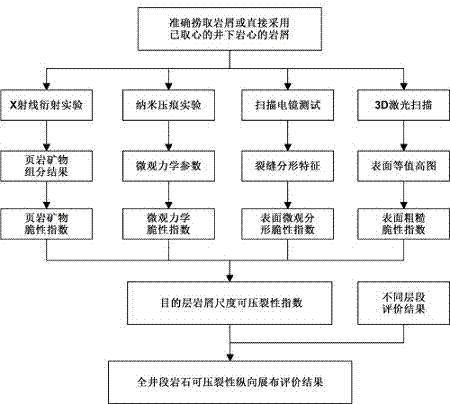

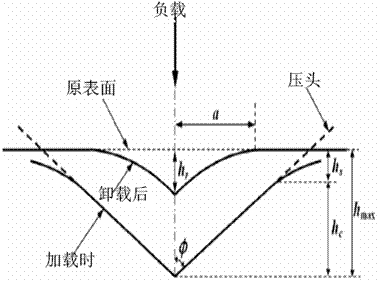

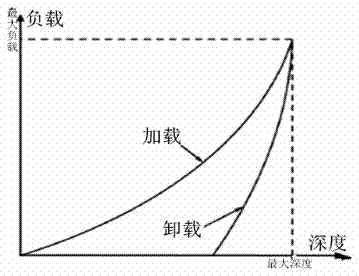

[0035] Take the relevant data of well R in a certain area as an example, such as figure 1 figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention is a shale fracturing evaluation method based on the microscopic characteristics of cuttings, and the method includes the following steps:

[0036] ① Take the shale cuttings at a specific depth of the reservoir, collect the cuttings accurately, and measure the late time according to the specified time interval to ensure the continuity and representativeness of the cuttings. Eliminate fake rock fragments with blurry tone, unobvious edges and corners, and larger individuals (non-stratification); or directly use cored core fragments. After the test cuttings are obtained, the cuttings are cleaned and dried to remove the drilling fluid attached to the surface. According to the requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com