A method for evaluating the mechanical properties of metal-based copper-clad laminates

A copper-clad laminate, metal-based technology, applied in the direction of applying a stable bending force to test the strength of materials, etc., can solve the problem of inability to achieve accurate quantitative evaluation, inability to distinguish the bending properties of metal substrates, and inability to achieve quantitative evaluation, etc. Questions, to achieve the effect of simple and quick evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

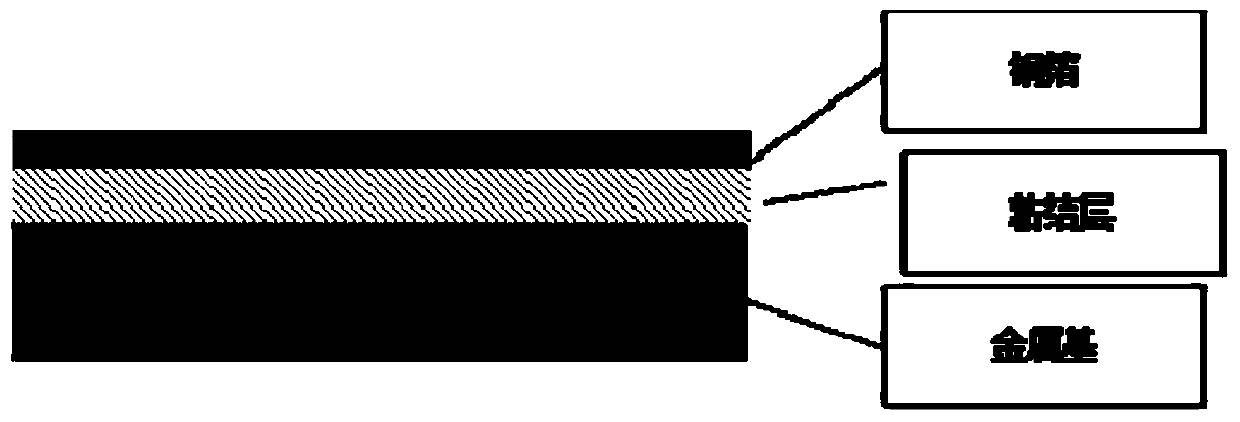

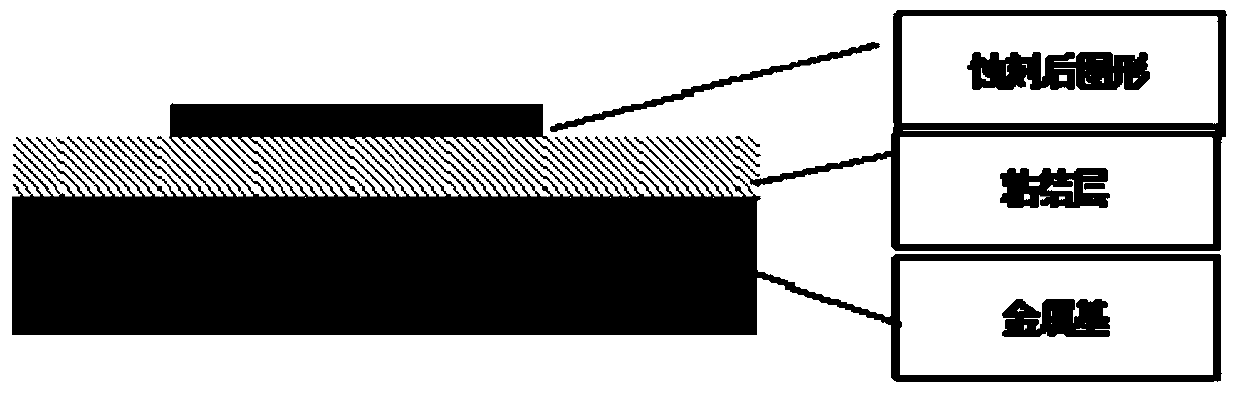

[0032] Cut the metal-based copper-clad laminate A to be tested into 6 samples with a width of 100 mm and a length of 100 mm, and etch the middle copper foil of the sample to be tested into a circle with a diameter of 50 mm.

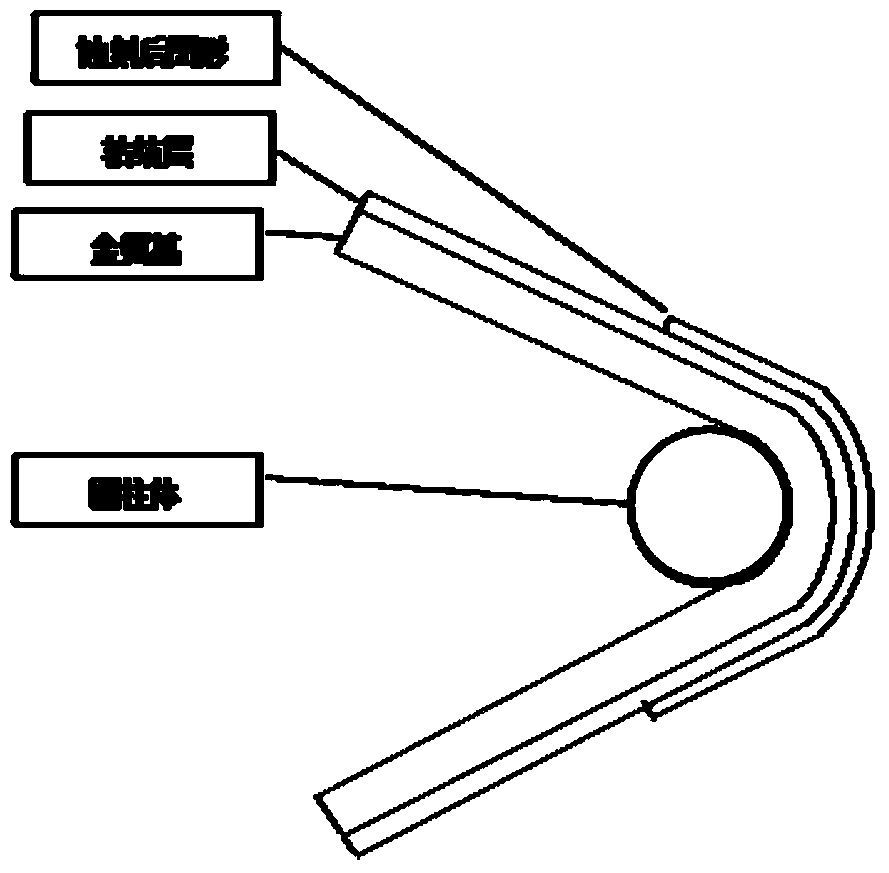

[0033] Divide the samples to be tested into two groups (A1 and A2), with 3 pieces in each group, bend the A2 sample with the copper side outward and bend it at 90° with a bending radius of 2mm, and divide the bent A2 sample and the unbent The A1 sample is subjected to a withstand voltage test, and the DC voltage is set to 5000V, and the leakage current is 0.1mA. A1 group samples can withstand voltage values of 5000V, 5000V, 5000V; A2 group samples can withstand voltage values of 5000V, 5000V, 5000V; record and compare the actual withstand voltage values of the two groups of samples. rate of 100%), the material has good bending resistance.

Embodiment 2

[0035] Cut the metal-based copper-clad laminate B to be tested into 6 samples with a width of 100 mm and a length of 100 mm, and etch the middle copper foil of the sample to be tested into a circle with a diameter of 50 mm.

[0036] Divide the samples to be tested into two groups (B1 and B2), 3 pieces in each group, bend the copper side of the B2 sample outwards and bend it 90° with a bending radius of 2 mm, and divide the bent B2 sample and the unbent The B1 sample is subjected to a withstand voltage test, and the DC voltage is set to 5000V, and the leakage current is 0.1mA. B1 group samples can withstand voltage values of 5000V, 5000V, 5000V; B2 group samples can withstand voltage values of 3500V, 3000V, 3000V; record and compare the actual withstand voltage values of the two groups of samples, and the average retention rate of the sample withstand voltage values after bending It is 63% (the retention rate is less than 80%), and the pressure resistance level of the s...

Embodiment 3

[0038] Cut the metal-based copper-clad laminate C to be tested into 6 samples with a width of 100 mm and a length of 100 mm, and etch the middle copper foil of the sample to be tested into a circle with a diameter of 50 mm.

[0039] Divide the samples to be tested into two groups (C1 and C2), with 3 pieces in each group, bend the C2 sample with the copper side outward and bend it at 90° with a bending radius of 2mm, and divide the bent C2 sample and the unbent The C1 sample is subjected to a withstand voltage test, and the DC voltage is set to 5000V, and the leakage current is 0.1mA. C1 group samples can withstand voltage values of 5000V, 5000V, 5000V; C2 group samples can withstand voltage values of 4500V, 4200V, 4500V; record and compare the actual withstand voltage values of the two groups of samples, and the average retention rate of the sample withstand voltage values after bending It is 88% (the retention rate is greater than 80%), and the pressure resistance lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com