Novel composite glass fiber reinforced plastic pressure tank composed of poly ethylene (PE) inner container layer and winding layer

A fiberglass tank and liner layer technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of long manual production period, low degree of standardization, and low production efficiency, and achieve light weight and integrity Good, high applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

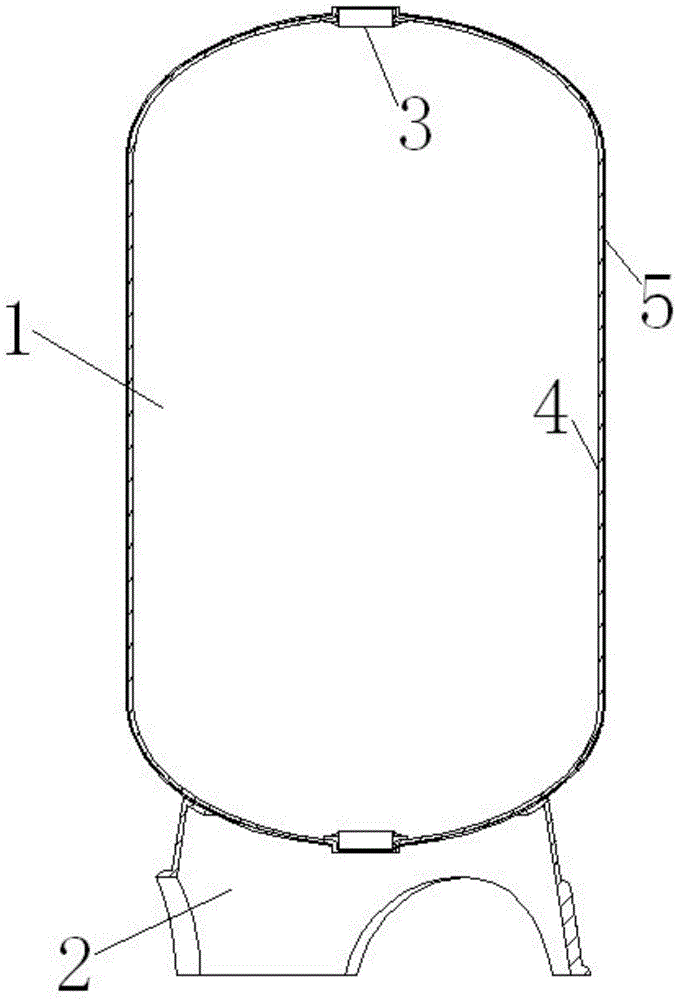

[0023] Such as figure 1 , figure 2 and image 3 As shown, a new type of FRP pressure tank with PE liner layer and winding layer composite according to the present invention, it includes a FRP tank body 1, a base 2 is arranged at the bottom of the FRP tank body 1, and a base 2 is arranged on the FRP tank body 1 The tank mouth 3 is provided at the top and the bottom, and the FRP tank body 1 is composed of an inner liner layer 4 and a winding layer 5, the inner liner layer 4 is a PE inner liner layer, and the winding layer 5 is directly mixed with glass fiber roving High-performance epoxy resin winding layer, the tank mouth 3 and the liner layer 4 are integrally formed; the tank mouth 3 is divided into a threaded interface tank mouth and an aluminum alloy flange tank mouth; the diameter of the threaded interface tank mouth is 4inch; the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com