Combined well mouth testing device for polymer injection well and method thereof

A technology for combined testing and polymer injection wells, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc. It can solve the problems of inability to monitor the actual change of viscosity, inability to accurately describe the seepage characteristics of polymer solution, and difficulty in viscosity distribution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

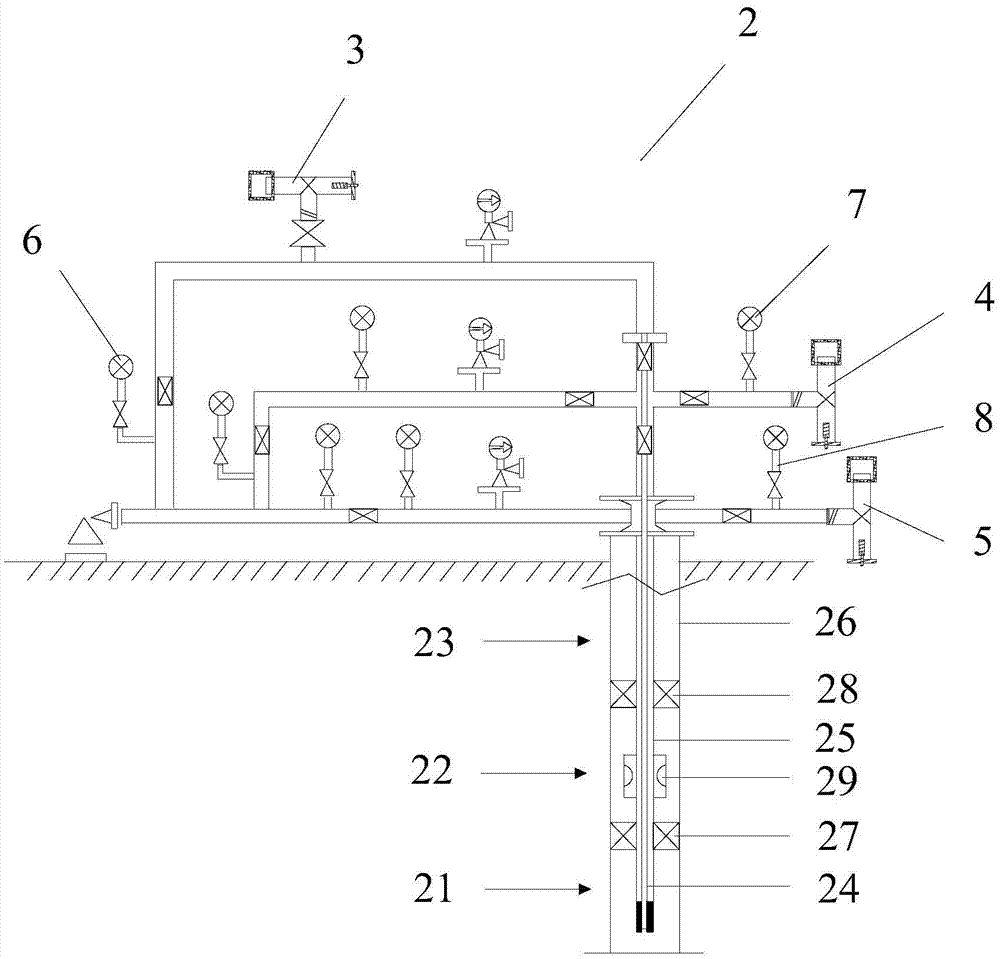

[0076] This embodiment is taken from an injection well in a certain oil field. Water was injected in December 2009, and polymer solution was injected in April 2011. The concentration of the injected polymer solution was 2000mg / l, and the thickness of each layer from bottom to top was respectively 8m, 8m and 10m. The injection was stopped on April 22, 2012, and the pressure drop was measured for 2.5 days.

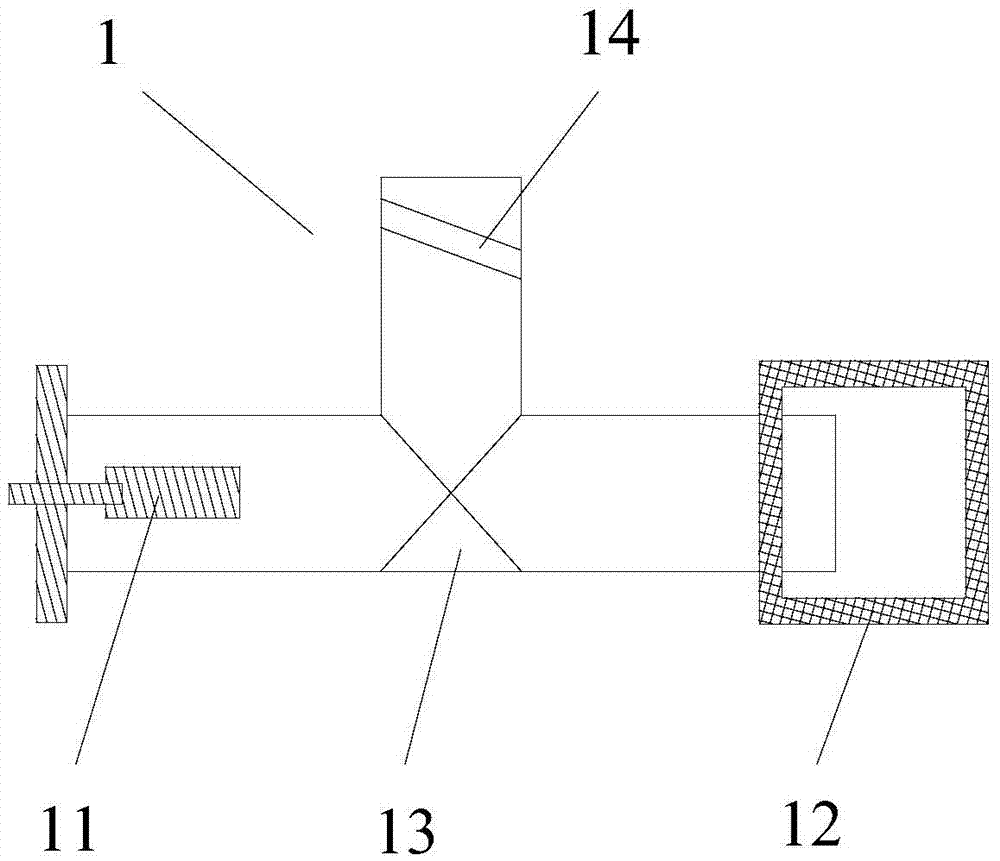

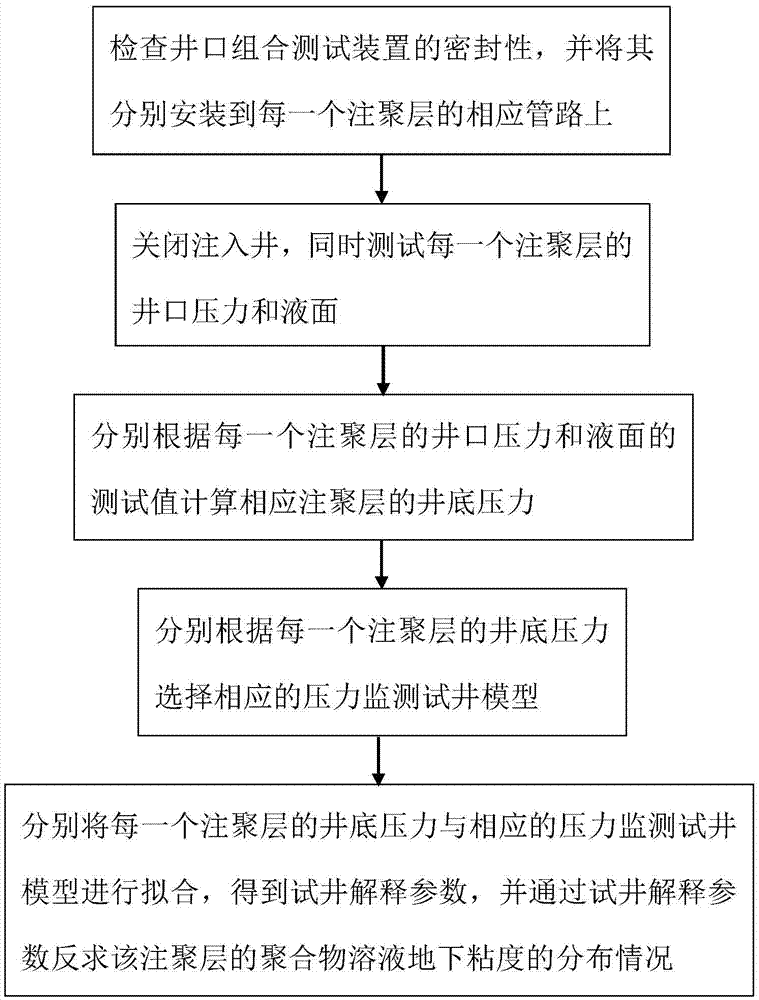

[0077] Such as figure 1 As shown, according to an embodiment of the wellhead combination testing device 1 for polymer injection wells of the present invention, it includes a high-precision pressure monitor 11, a continuous liquid level monitor 12 and a three-way valve 13, and the high-precision pressure monitor 11 and the continuous liquid level monitor 12 are connected in combination with the three-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com