A method for improving the air permeability of paint-dyed fabric

A paint dyeing and air permeability technology is applied in the field of improving the air permeability of paint dyed fabrics and physical pretreatment to improve the air permeability of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

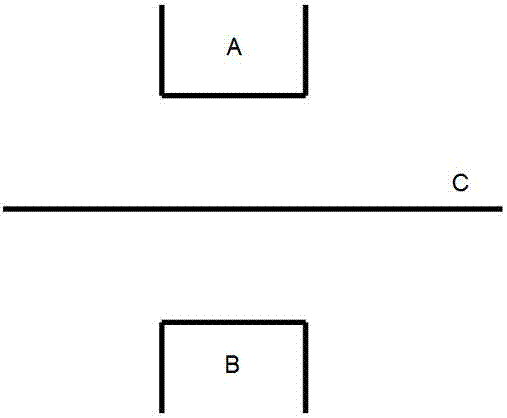

[0013] Example 1 In the whole process of fabric C paint dyeing, a negative pressure suction device is set between fabric C padding and pre-drying process, after fabric C padding paint, undried fabric C passes through There is a negative pressure suction device area, the negative pressure of the suction port of the upper suction device A and the suction port of the lower suction device B is 1MPa, and the upper surface of the fabric C is the same as the plane of the suction port of the upper suction device A The distance is 0.1 cm, the distance between the lower surface of fabric C and the air outlet of lower suction device B is 0.1 cm, and part of the paint dye solution in fabric C is sucked out from the upper surface of fabric C through the air outlet of upper suction device A. Part of the paint dye liquor is sucked out from the lower surface of the fabric C through the air outlet of the lower suction device B, and then enters the pre-drying process, wherein the pre-drying temp...

Embodiment 2

[0014] Example 2 In the whole process of fabric C dyeing with paint, a negative pressure suction device is set between the padding of fabric C and the pre-drying process. After fabric C is padded with paint, the undried fabric C passes through There is a negative pressure suction device area, the negative pressure of the suction port of the upper suction device A and the suction port of the lower suction device B are both 5MPa, and the upper surface of the fabric C is the same as the plane of the suction port of the upper suction device A The distance is 0.3cm, the distance between the lower surface of fabric C and the air outlet of lower suction air device B is 0.3cm, and part of the paint dye solution in fabric C is sucked out by the upper surface of fabric C through the air outlet of upper suction air device A. Part of the paint dye liquor is sucked out from the lower surface of the fabric C through the air outlet of the lower suction device B, and then enters the pre-drying...

Embodiment 3

[0015] Example 3 In the whole process of fabric C dyeing with paint, a negative pressure suction device is set between the padding of fabric C and the pre-drying process. After fabric C is padded with paint, the undried fabric C passes through There is a negative pressure suction device area, the negative pressure of the suction port of the upper suction device A and the suction port of the lower suction device B are both 3MPa, and the upper surface of the fabric C is the same as the plane of the suction port of the upper suction device A The distance is 0.2cm, the distance between the lower surface of fabric C and the air outlet of lower suction air device B is 0.2cm, and part of the paint dye solution in fabric C is sucked out by the upper surface of fabric C through the air outlet of upper suction air device A. Part of the paint dye liquor is sucked out from the lower surface of the fabric C through the air outlet of the lower suction device B, and then enters the pre-drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com